Knitted fabric, making method and use device for knitted fabric and garment made from knitted fabric

A technology for knitted fabrics and clothing, applied in the field of fabrics and clothing, can solve problems such as reduction, and achieve the effects of good width, reduced shrinkage and less hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

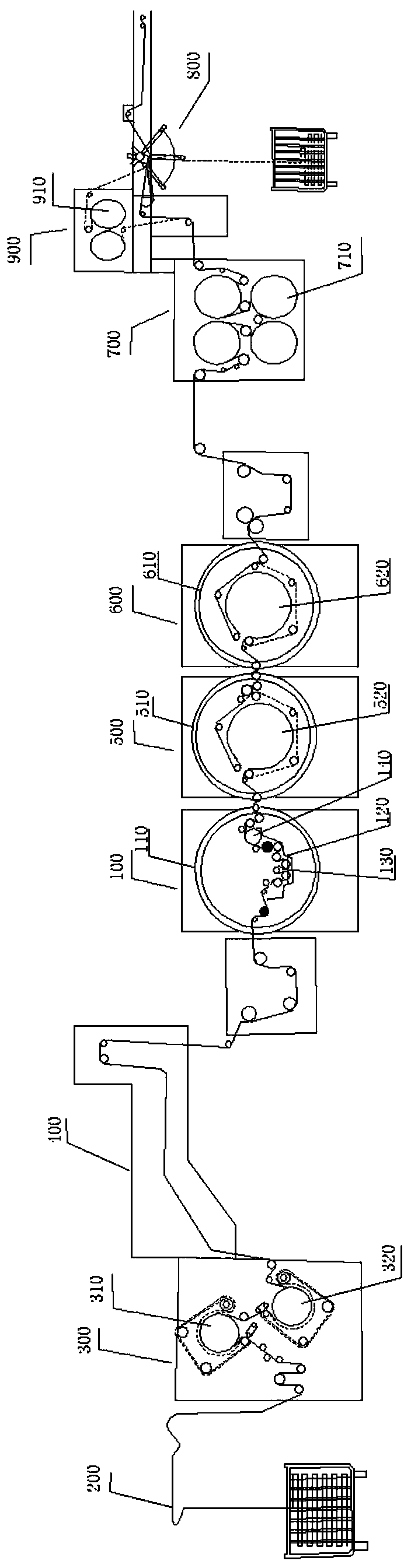

Method used

Image

Examples

Embodiment 1

[0111] The dyeing of embodiment 1 yarn

[0112] 100% pure cotton combed cotton yarns 1#-4# of 4 different finenesses are dyed, and the steps of dyeing include:

[0113] (1) Loose winding process: the yarn is wound layer by layer onto the dyeing tube to form a bobbin yarn with a density of 0.38-0.4g / m 3 ;

[0114] (2) cheese dyeing process: the dyeing process is:

[0115] ①Pretreatment step: Mix 0.3-0.5g / L chelating agent, 3g / L-4g / l refining agent, 3g / L-4g / l caustic soda and 6g / L-8g / l hydrogen peroxide at 60°C and heat at 100°C Reaction 40min;

[0116] ② Dyeing step: react at 80°C for 5 minutes, cool down to 55°C, add 0.8-1.2g / L neutralizing acid, 0.1-0.2g / L deoxygenase, then raise the temperature to 55°C and keep for 20min, then cool down to 50°C Add 3%-5% dye, 10-20g / L

[0117] For Yuan Mingfen, heat up to 60°C for 15 minutes, add soda ash, keep for 40 minutes, cool down to 50°C and add soap, heat up to 98°C for 15 minutes.

[0118] (3) Knitting process: the dyed yarn i...

Embodiment 2

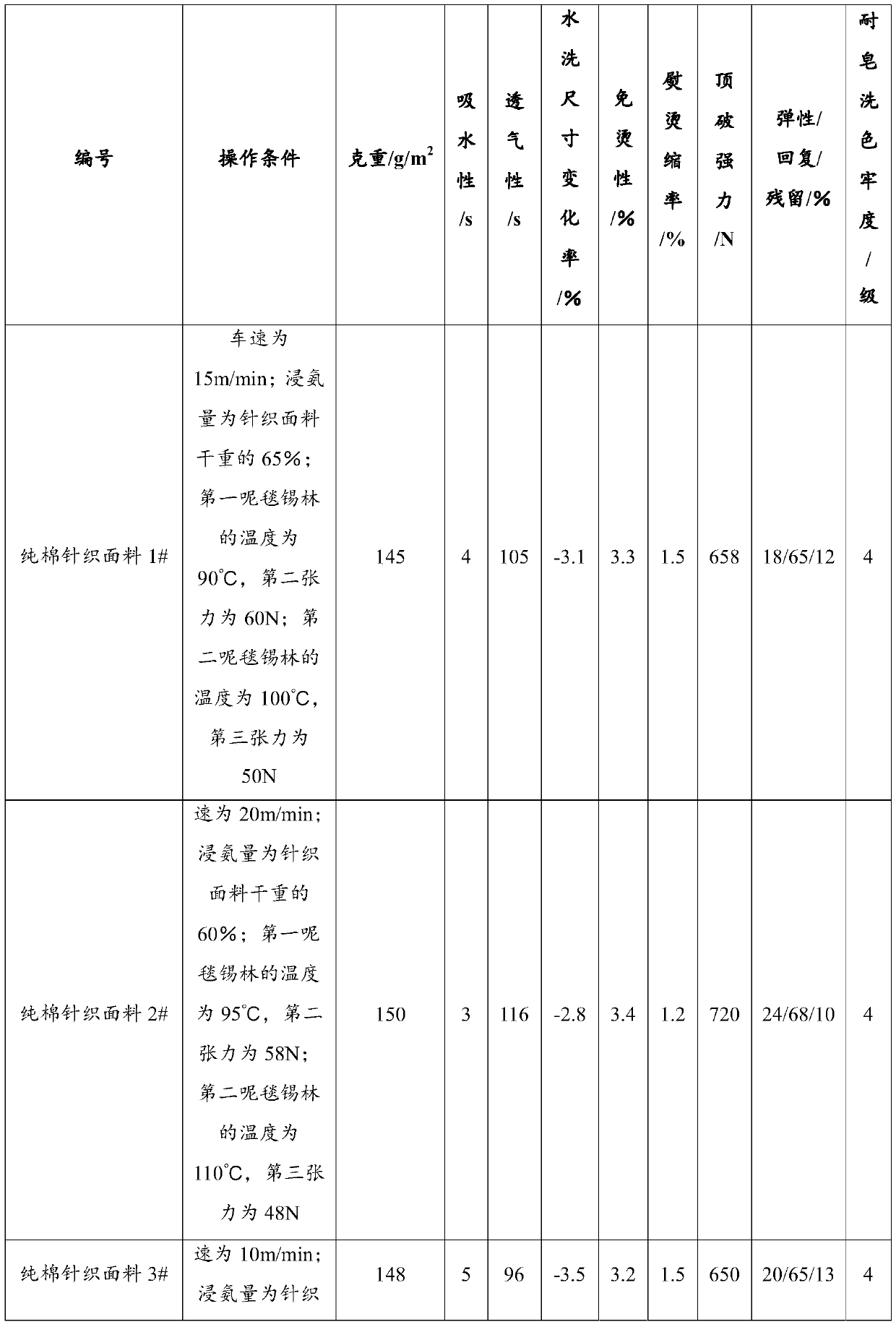

[0128] Embodiment 2 liquid ammonia finishing

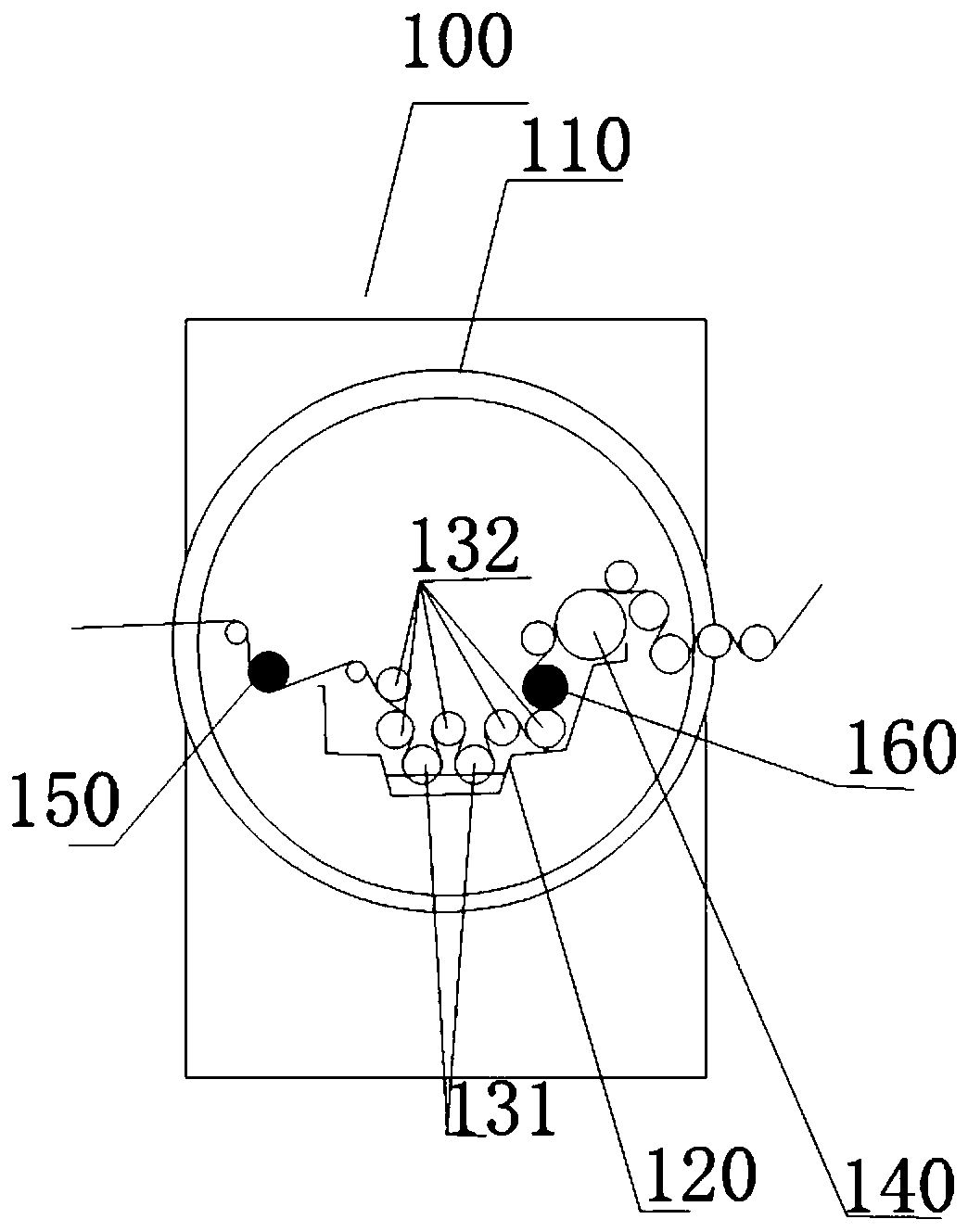

[0129] The 75 100% combed cotton yarns dyed in Example 1 are subjected to functional after-finishing including the liquid ammonia finishing process through the pure cotton knitted fabric 1# weaved by weft knitting, and the speed of the liquid ammonia finishing process is 10- 25m / min, the surface of the guide roller is made of rubber material, including the following steps:

[0130] 1) adjusting the moisture content of the knitted fabric to be lower than 10%;

[0131] 2) The knitted fabric prepared in step 1) is soaked in ammonia twice in the ammonia soaking tank through the guide roller group 130, and the ammonia soaking amount is controlled to be 30%-70% of the dry weight of the knitted fabric, and the padding pressure is 70bar~100bar ;

[0132] 3) Pass the knitted fabric prepared in step 2) through the first felt cylinder of the reaction unit, the temperature of which is 90-110°C, and the second tension is 54-67N;

[0133] 4)...

Embodiment 3

[0141] Embodiment 3 stereotype finishing

[0142] The pure cotton knitted fabric 1# obtained in Example 2 was subjected to a shaping finishing process to obtain pure cotton knitted fabrics 5#-8# and comparative pure cotton knitted fabrics D5#-D7#. The setting temperature of the setting finishing process is

[0143] 160-200°C, the speed of shaping machine is 25-35m / min.

[0144] Styling agents include: 10-100g / L Shanghai Yayun KC-77 softener, 10-60g / L Huntsman SI polyurethane elastic additive, 20-100g / L Huntsman RCT resin, 4-30g / L Huntsman MO catalyst and 10-60g / L Hong Kong Advanced Chemicals HI-40 fiber protection agent.

[0145] The parameters and test structure of the specific finishing process of pure cotton knitted fabrics 5#-7# and comparative pure cotton knitted fabrics D5#-D7# are shown in Table 4. Among them, the test method of air permeability (mm / s) refers to GB / T 5453; the test method of washing dimensional change rate (%) is: ISO 6330; the test of non-ironing (g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com