Apparatus for processing fiber and yarn by liquid ammonia

A liquid ammonia treatment and fiber technology is applied in the field of liquid ammonia treatment fibers and yarn devices, which can solve the problems of increased ammonia recycling cost and yarn re-drying, increased energy for liquid ammonia recycling, and large amount of ammonia. To achieve the effect of shortening the processing process, reducing the processing cost and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

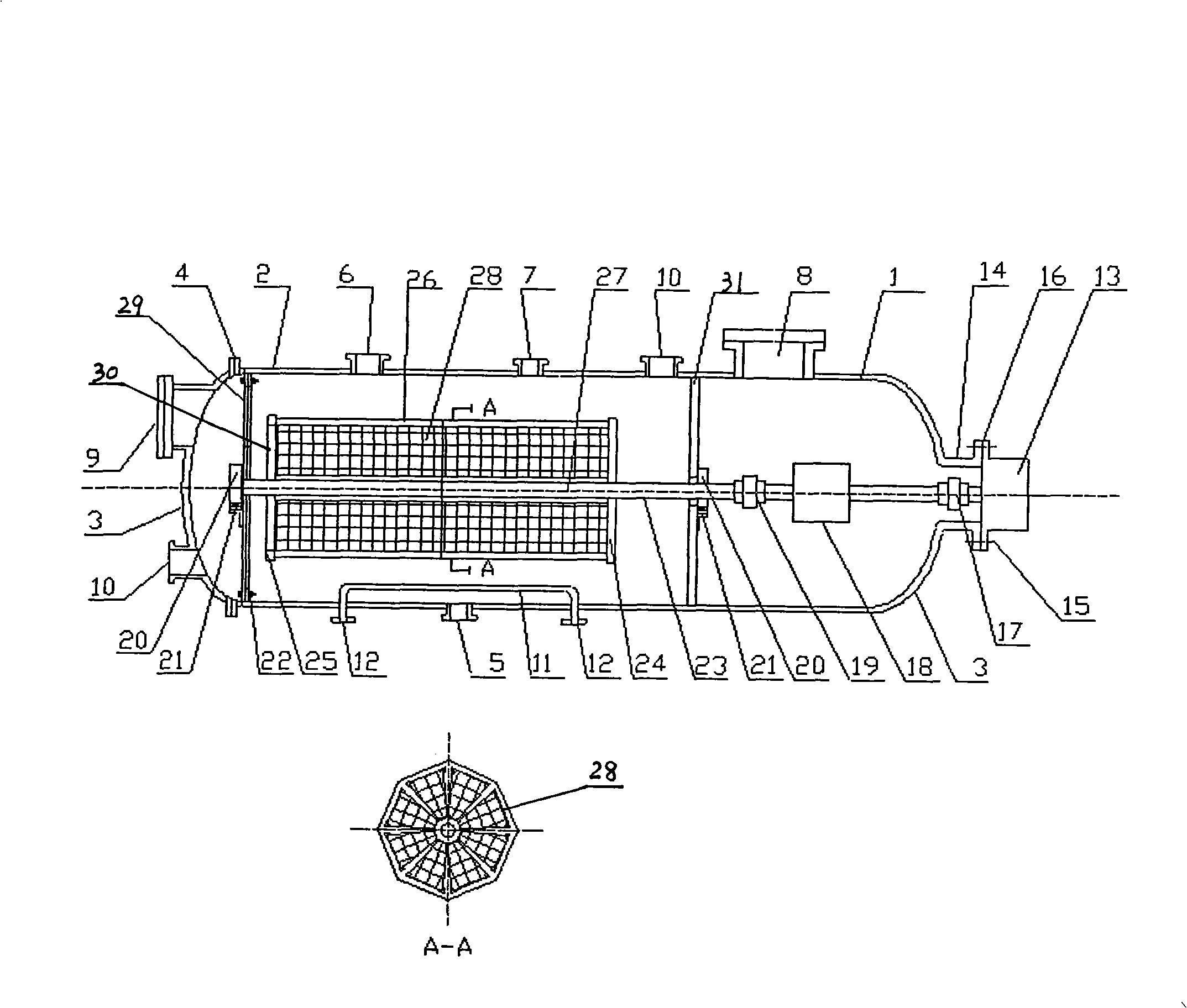

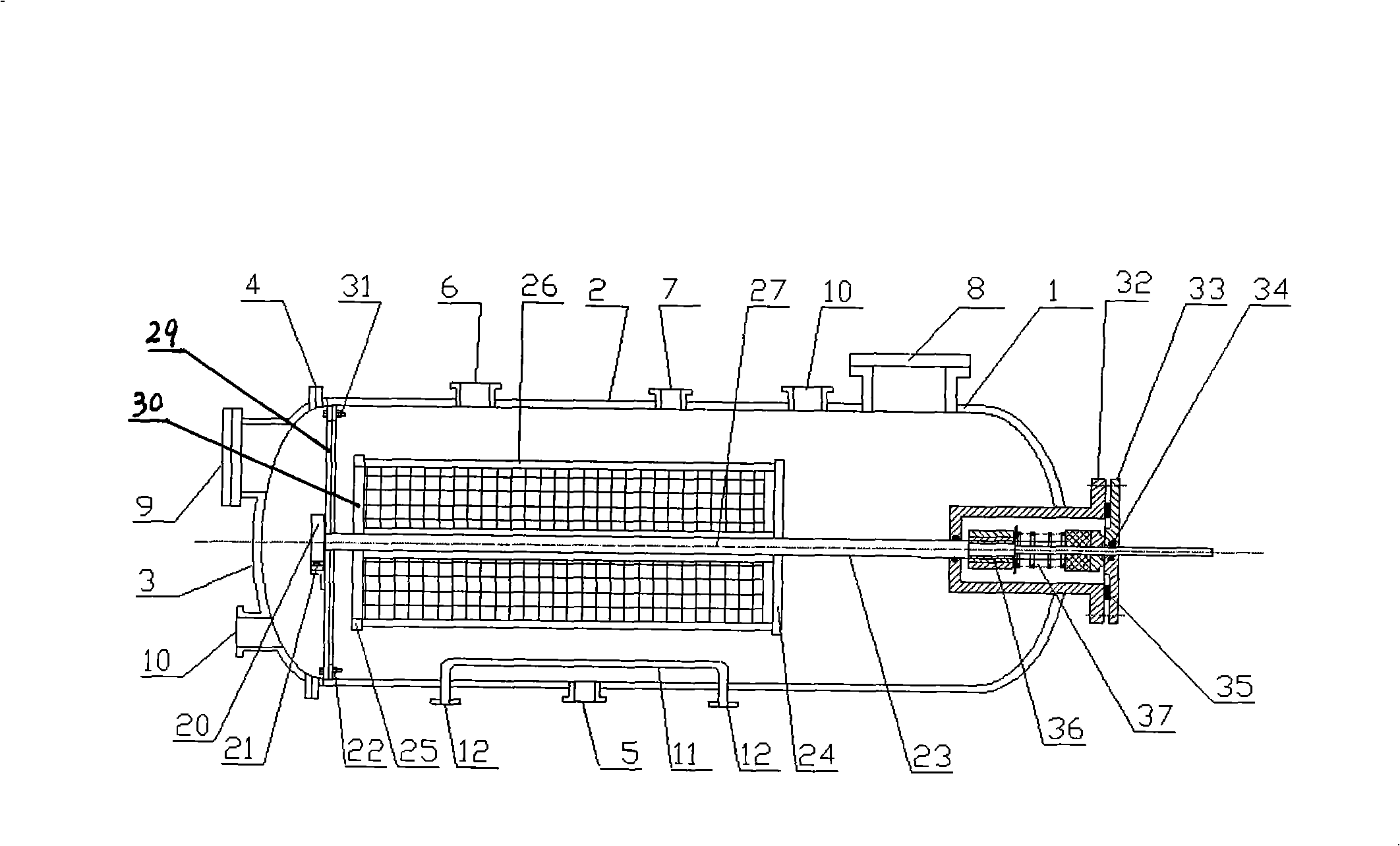

[0013] see figure 1 , figure 2 The device for treating fibers and yarns with liquid ammonia in the present invention includes a horizontal pressure tank 1, the tank body 1 is composed of a cylinder 2 and two end caps 3, and the left end cap 3 and the cylinder part 2 are flanged 4 connections, the installation of the device in the tank can be carried out by opening the head. The tank body is equipped with liquid ammonia inlet and outlet 5, ammonia gas outlet 6, physical parameter detection, display and safety valve interface 7, manholes and hand holes for easy maintenance. Holes 8, raw material import and export 9 that can be closed and opened, hot gas import and export 10 for conveying hot air, hot water or hot steam import and export 12. A heating pipe 11 connected to an inlet and outlet 12 of hot water or hot steam is arranged in the tank body. The working pressure of the horizontal pressure tank 1 can reach 2.2MPa, and the working temperature is -33~90°C.

[0014] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com