Packaging glue film without flanging and with good bonding

A kind of encapsulating adhesive film, good technology, applied in the field of solar cells, can solve problems such as poor bonding of the backplane, lower module output power, and battery sheet shading, etc., achieve good appearance, control shrinkage rate, and increase power generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

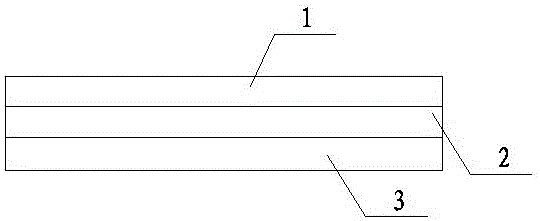

[0026] This embodiment provides an encapsulating adhesive film with no flanging and good adhesion, which includes a first transparent layer 1, a middle non-transparent layer 2 and a second transparent layer 3 arranged in sequence, the first transparent layer 1, the middle non-transparent layer 2 and the second transparent layer 3 are independently EVA, POE or a polymer substrate mixed with POE and LDPE; the polymer substrate of the middle non-transparent layer 2 also contains inorganic pigment powder.

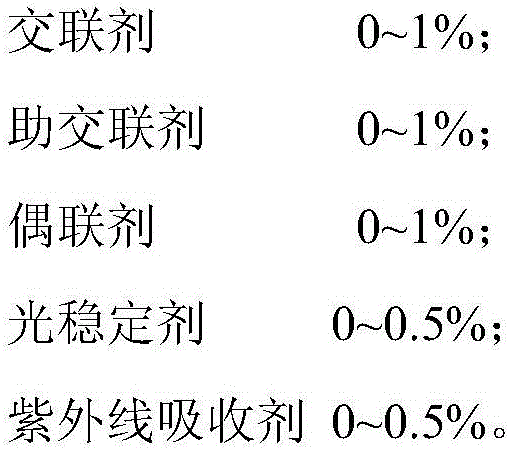

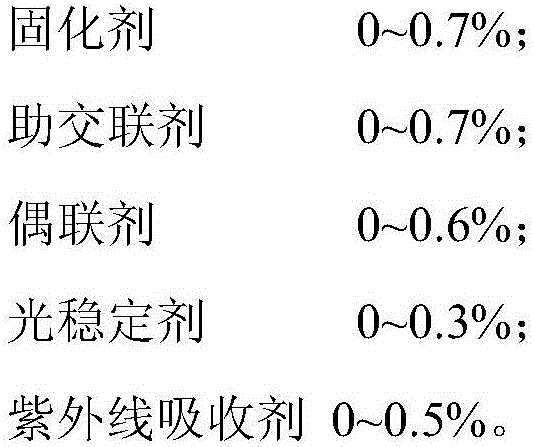

[0027] Wherein, the thickness of the first transparent layer 1 (that is, the A1 layer) is 200 μm, and its specific components are: the polymer substrate is POE (DOW company XUS38660, 100 wt%), and the following components are added in the mass fraction thereof: Parts: TBEC (acrylic curing agent, tert-butylperoxycarbonate-2-ethylhexyl) 0.7wt%, TAIC (assistant crosslinking agent, triallyl isocyanurate) 0.7wt%, coupling Agent OFS-6030: 0.6wt%, light stabilizer Tinuvin 770: 0.3wt%,...

Embodiment 2

[0031] This embodiment provides a kind of encapsulating adhesive film with no flanging and good adhesion, its structure is consistent with that of Embodiment 1, and the composition and thickness of the first transparent layer 1 and the second transparent layer 3 are also the same as those of Embodiment 1. The same as in , the difference is that a different intermediate non-transparent layer 2 is used, specifically:

[0032] The thickness of the middle opaque layer 2 (i.e. B layer) is still 300 μm, but its specific components are: the polymer substrate is POE (DOW company XUS38660, 70wt%), LDPE (2426H, 20wt%) and titanium dioxide (10wt%) %) composition, the following components are also added in the mass fraction: TBEC: 0.63wt%, TAIC: 0.63wt%, 6030: 0.54wt% and 770: 0.27wt%.

Embodiment 3

[0034] This embodiment provides a kind of encapsulant film with no flanging and good adhesion, its structure is consistent with that in embodiment 2, and the composition and thickness of the middle non-transparent layer 2 (i.e. B layer) are also the same as in embodiment 2 The difference is that the first transparent layer 1 and the second transparent layer 3 in the middle are used, specifically:

[0035] The thickness of the first transparent layer 1 is 200 μm, and its specific components are as follows: the polymer substrate is composed of POE (38660, 80wt%) and LDPE (2426H, 20wt%), and the following components are added in the mass fraction thereof: Parts: TBEC (acrylic curing agent, tert-butylperoxycarbonate-2-ethylhexyl) 0.7wt%, TAIC (assistant crosslinking agent, triallyl isocyanurate) 0.7wt%, coupling Agent 6030: 0.6wt%, light stabilizer 770: 0.3wt%, ultraviolet absorber (CYASORB UV-531) 0.35wt%.

[0036] The thickness of the second transparent layer 3 (that is, the A2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com