Patents

Literature

40results about How to "Reduce fold ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-component high-performance mortar for repairing and reinforcing concrete

InactiveCN101935201AShrinkage controlImprove bindingSolid waste managementFlexural strengthPollution

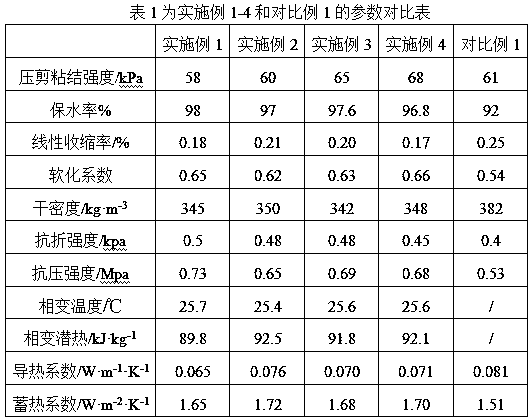

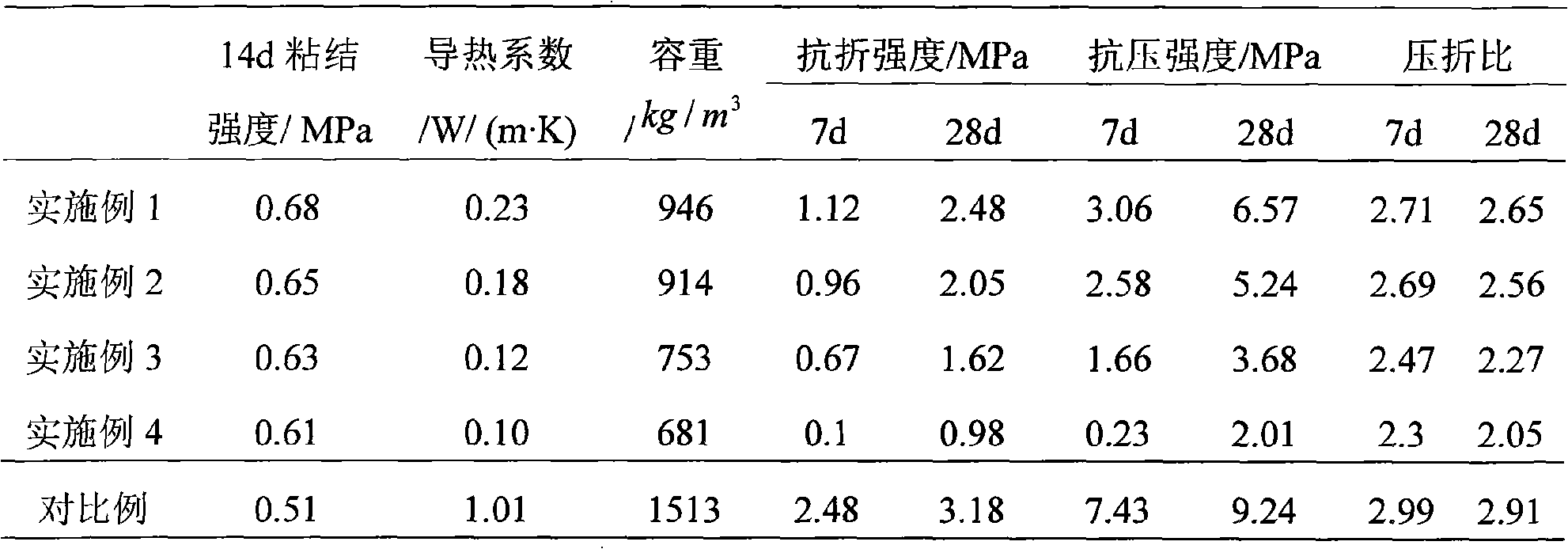

The invention provides single-component t high-performance mortar for repairing and reinforcing concrete, which comprises the following components in part by mass: 200g of sand, 55 to 75 parts of ordinary portland cement, 10 to 30 parts of sulphate aluminium cement, 3 to 7 parts of siliceous dust, 8 to 12 parts of flyash, 0.18 to 0.22 part of water reducing agent, 2 to 4 parts of flexibilizer, 0.04 to 0.06 part of water-retaining agent, 1.0 to 2.0 parts of swelling agent and 0.1 to 0.2 part of polymer synthetic fiber. The single-component t high-performance mortar has the advantages of high initial strength, good adhesion, excellent cracking resistance, low ratio of compressive strength to flexural strength, excellent toughness, simple and convenient construction, single component, no toxin or smell, no harm to human bodies, and environmental protection without pollution.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

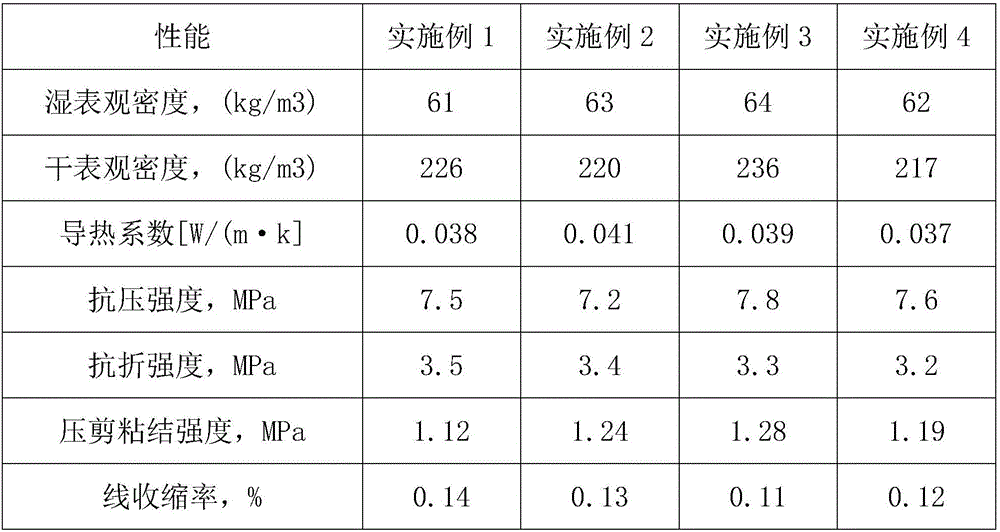

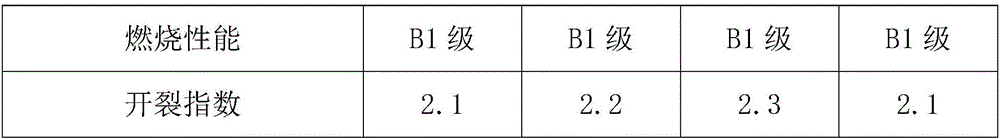

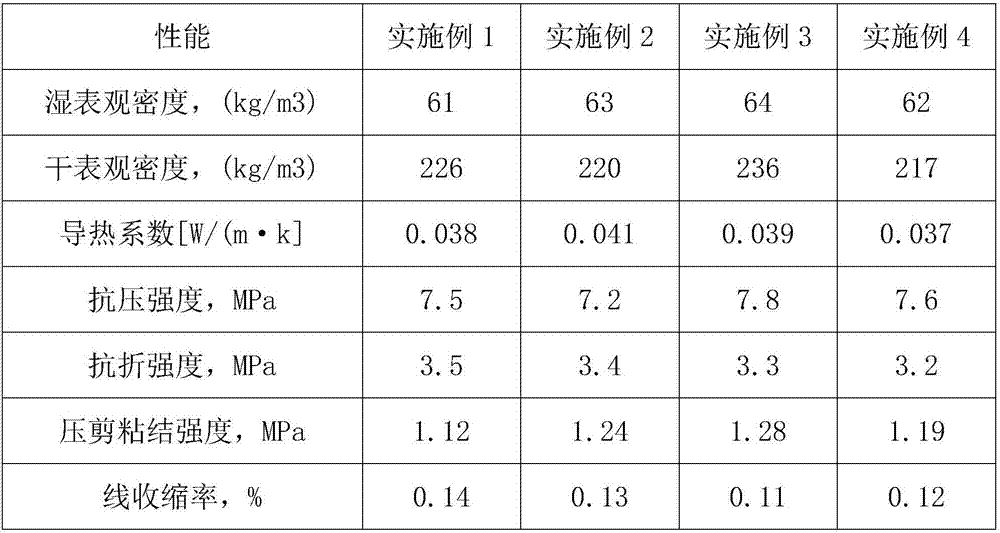

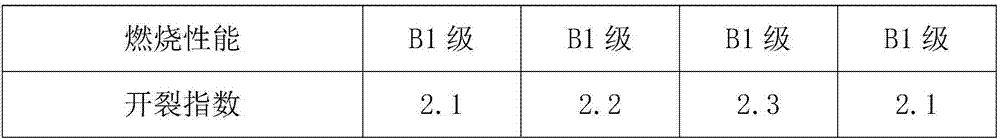

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar

InactiveCN102690091AEliminate hot and cold bridgesEliminate hot and cold bridge phenomenonThermal insulationMicrosphere

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, especially a wall self-insulation system-matching hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, relate to a constuction energy-saving technology. The hollow microsphere masonry dedicated thermal insulation mortar comprises, by weight, 20-30% of special cement, 2-6% of coal ash, 20-35% of quartz sand, 5-8% of master batch, 35-45% of hollow microphere, and 3-6% of coarse whiting; and the hollow microsphere masonry dedicated surface mortar comprises, by weight, 28-40% of ordinary Portland cement, 3-6% of coal ash, 7-10% polymer, 40-55% of quartz sand, 10-16% of hollow microsphere, and 1-3% of coarse whiting. With a low heat conductivity coefficient, excellent thermal insulation effect, high compression strength, high bonding strength, low contractibility, environment-friendly and fire-proof properties and notable composite economic results, the wall self-insulation system-matching dedicated thermal insulation mortar and a dedicated surface mortar provided in the invention can be widely popularized and used in wall self-insulation system buildings.

Owner:HUBEI TIANQUAN NEW BUILDING MATERIALS

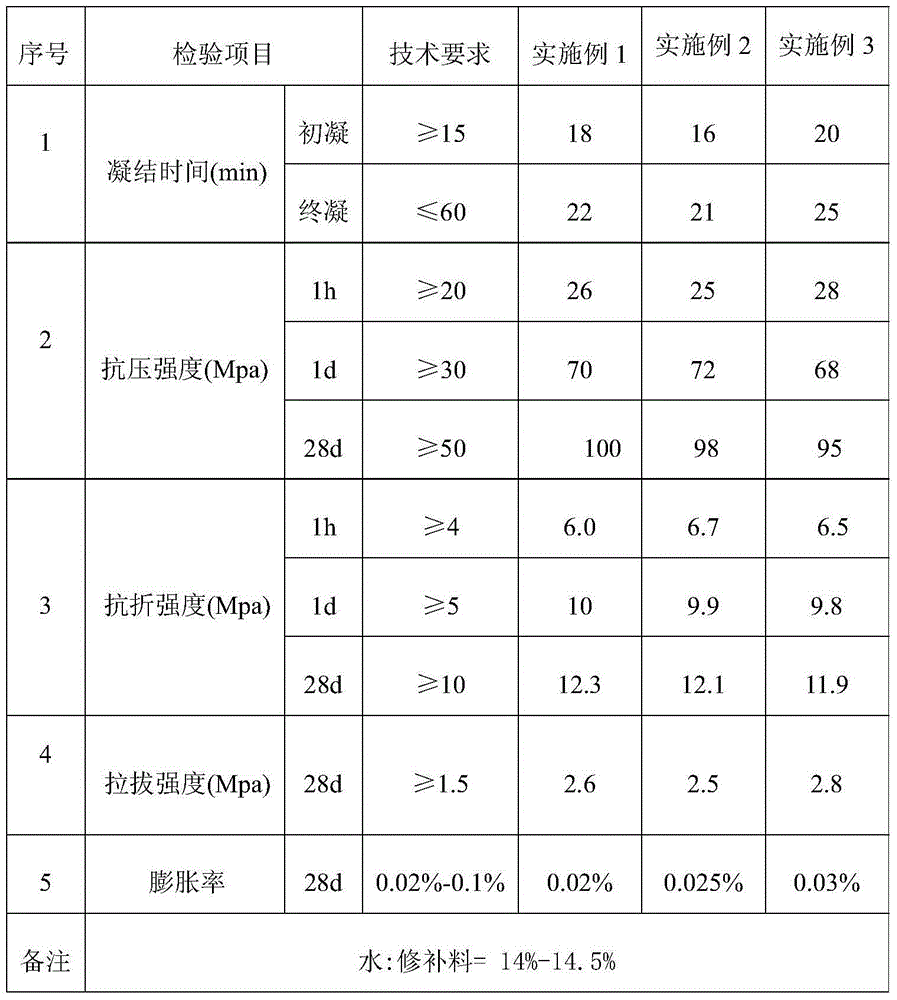

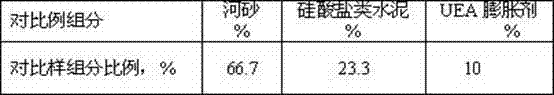

Pavement/bridge deck concrete fast mending material and application thereof

The invention relates to a pavement / bridge deck concrete fast mending material and application thereof. The mending material comprises the following raw materials by weight: 20 to 30 parts of sulphoaluminate cement, 8 to 10 parts of ordinary Portland cement 52.5, 5 to 10 parts of polymer powder, 0.5 to 1.5 parts of aluminium sulphate, 1 to 2 parts of water glass, 0.1 to 1 part of organic silicon, 1 to 2 parts of gypsum, 2 to 3 parts of slag, 0.1 to 0.5 part of silica micropowder, 0.5 to 1 part of an HPCA high-performance concrete expansive material, 3 to 5 parts of fly ash, 20 to 30 parts of washed-out and dried sand, 25 to 30 parts of corundum, 3 to 5 parts of composite fiber, 1 to 3 parts of a polycarboxylate superplasticizer, 0.1 to 0.5 part of boric acid, 0.1 to 0.3 part of sodium gluconate, and 0.2 to 1 part of lithium carbonate. The mending material is high in early strength, and has the advantages that traffic can be opened fast only 1 to 2 hours after mending is completed, so as to reduce traffic jams, and effectively reduce the generation of traffic accidents.

Owner:HENAN HUINENG ROAD & BRIDGE TECH CO LTD

Hydrophobic thermal insulation and anti-cracking mortar for external wall and method for preparing same

The invention discloses a hydrophobic outer wall heat-preservation anti-cracking mortar and a method for making the same. The mortar takes cement and fine sand as base materials, and is formed through adding in hydrophobic active chemical substances, i.e. a water retention agent and corresponding agglomerant, an expansion agent and fiber; the waterproof function of the mortar is that the hydrophobic active chemical substances can be absorbed on the inner surface of the pore of cement mortar so as to form a hydrophobic surface film, thereby preventing outside moisture from infiltrating into the mortar and reaching the action of water proofing and leakage resistance. The hydrophobic outer wall heat-preservation anti-cracking mortar has the advantages of water proofing, cracking prevention, leakage resistance, heat preservation, heat insulation, excellent bonding property, high strength, low degree of shrinkage, low coefficient of thermal conductivity, ideal workability and application property and low fold ratio, and is a novel heat-preservation heat-insulation material. The heat-preservation heat-insulation building built by the mortar is not cold in winter and not hot in summer indoors, thereby greatly improving dwelling environment and saving energy resources; moreover, all indexes and particularly the hydrophobic index of the mortar are up to advanced domestic level, and have remarkable social benefit and economic benefit.

Owner:NANCHANG BOKANGTE BUILDING MATERIAL

Large adulteration quantity fly ash gel material for building mortar and preparation method thereof

InactiveCN101143775AReduce fold ratioImprove crack resistanceSolid waste managementThermal insulationSulfate

A highly-contented fly ash cementitious material for building mortar and manufacturing method thereof is obtained through high-speed stirring and mixing of raw materials at a rate by weight percent of: 55 percent-80 percent of fly ash, 5 percent-35 percent of cement, 2 percent-10 percent of siliceous dust, 0.5 percent-8 percent of alkali metal sulfate and 1 percent-5 percent of alkali metal silicate. The invention can increase considerably the mixing proportion of fly ash in cementitious material, improve the construction performance and flexural strength of cementitious material, reduce the flexural rate of cementitious material and reduce water consumption for standard consistency; also the invention has advantages of low manufacturing cost and simple process, which can serve as protective mortar such as anti-cracking mortar for the coating of the thermal insulation layer, improve flexural strength of anti-cracking mortar; reduce flexural rate and elastic module, and improve the anti-cracking performance of mortar.

Owner:北京振利高新技术有限公司

Protection mortar specially used on building insulating layer and preparing method thereof

InactiveCN101234870AHigh impact strengthSimplify construction proceduresSolid waste managementFiberCrack resistance

The invention relates to protection mortar specially used in heat preservation layer in building and a preparation method. The protection mortar is a dry mixed powder somatotype mortar or ready-mixed somatotype mortar. The weight portions of each component is 4-30 portions of short steel fiber, 10-25 portions of powder material, 0.5-8 portions of water retaining agent 5-35 portions of aggregate, 0.5-30 portions of polymer cement modification material, 10-30 portions of water and 10-30 portions of cement. The protection mortar not only simplifies the operation process, but also has the advantages of strong impact resistance, low press-breaking rate, strong durability and excellent crack resistance.

Owner:CANADA CARA INSULATION TECH

Cheap high-flexibility plaster gluing slurry and its production

InactiveCN1982250AReduce brittlenessImprove flexibilitySolid waste managementPolymer modifiedPolymer science

A modified polymer finishing mortar for external-wall thermal-insulating system is prepared by adding into glue sand in proportion of 1:2.5, fixing polymer emulsion admixture with PAE and SAE, substituting cement with composite admixture and composite modifying by polymer and admixture. It's cheap and convenient, has lower mortar pressure fracture rate and better flexibility.

Owner:TONGJI UNIV

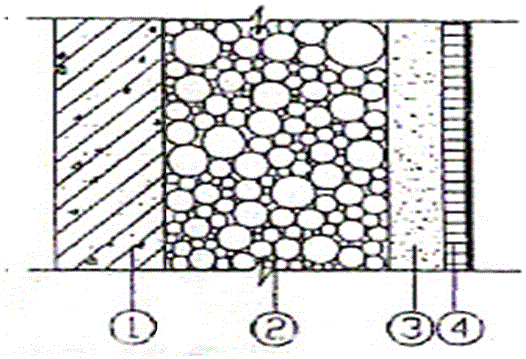

Energy-saving self-insulation wall and construction process

InactiveCN105155696AEliminate hot and cold bridge phenomenonImprove thermal insulation and energy savingWallsClimate change adaptationBuilding energyMicrosphere

The invention relates to the technical field of building energy saving, in particular to an energy-saving self-insulation wall and a construction process thereof. A self-insulation wall material is built into a self-insulation wall base through insulation mortar special for hollow microsphere masonry for the energy-saving self-insulation wall; a protective layer is made outside the self-insulation wall base through plaster mortar special for the hollow microsphere masonry; an impermeable anti-cracking layer is made outside the protective layer; a facing layer is made outside the impermeable anti-cracking layer; thus, the energy-saving self-insulation wall is formed. The insulation mortar and plaster mortar special for the hollow microsphere masonry have a small heat conductivity coefficient, high compressive strength, good adhesion, good workability, and small shrinkage, prevent energy loss of masonry mortar joints, eliminate 'cold and heat bridges' in blocks and greatly enhance insulation and energy-saving effects of the self-insulation wall, so that physical performance indexes of a building wall, such as thermal performance, are better than those in the standard for energy-saving self-insulation buildings. The energy-saving self-insulation wall is a building structure good in energy-saving and insulation effects, environment-friendly, fireproof and significant in economic benefit and is widely applicable to energy-saving self-insulation system buildings.

Owner:胡泉

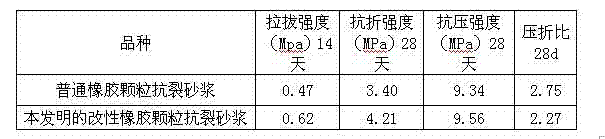

Modified rubber particles for mortar and preparation method of modified rubber particles

Disclosed are modified rubber particles for mortar and a preparation method of the modified rubber particles. The preparation method includes soaking rubber particles in alkali liquor; removing hydrophobic surface layers of the rubber particles so that rough surfaces of the rubber particles are exposed; washing the rubber particles by clear water; adding the treated rubber particles and a coupling modifier into a water bath container to stir the treated rubber particles and the coupling modifier under a water bath environment at the temperature ranging from 40 DEG C to 70 DEG C after the rubber particles are dried; and drying the mixture in the water bath container to obtain the modified rubber particles. The modified rubber particles for mortar and the preparation method have the advantages that affinity of the rubber particles and mortar is obviously enhanced by means of modification, cracking and pull strength of the mortar are improved, the ratio of compressive strength of mortar materials is reduced, and the modified rubber particles can be used as anti-crack components in the mortar in a building project. In addition, the surfaces of the rubber particles are corroded by the aid of alkali liquor treatment, the specific surface area is increased, accordingly, bonding with a coupling agent is enhanced, a modification effect is improved, and shearing force of the modified rubber particles and the mortar is increased.

Owner:北京振利节能环保科技股份有限公司

Anti-cracking heat-preserving wall construction material and preparation method thereof

The invention discloses an anti-cracking heat-preserving wall construction material and a preparation method thereof. The anti-cracking heat-preserving wall construction material is prepared from, by weight, 400-600 parts of cement, 40-70 parts of silica powder, 80-220 parts of ash-calcium powder, 80-160 parts of expanded vermiculite, 60-100 parts of sand, 60-100 parts of hollow glass beads, 40-80 parts of rock wool threads, 30-80 parts of modified fly ash, 60-120 parts of polyphenyl particles, 10-20 parts of wood fiber, 5-10 parts of polypropylene fiber, 30-60 parts of polyvinyl alcohol, 40-80 parts of dispersible latex powder and 10-20 parts of cellulose ether. The anti-cracking heat-preserving wall construction material solves the problem that finishing mortar prepared from an existing outer wall heat-preserving material is prone to cracking and poor in durability, and truly achieves heat preservation, heat isolation and high anti-cracking performance.

Owner:MAANSHAN TIANJINYUN PAINT IND

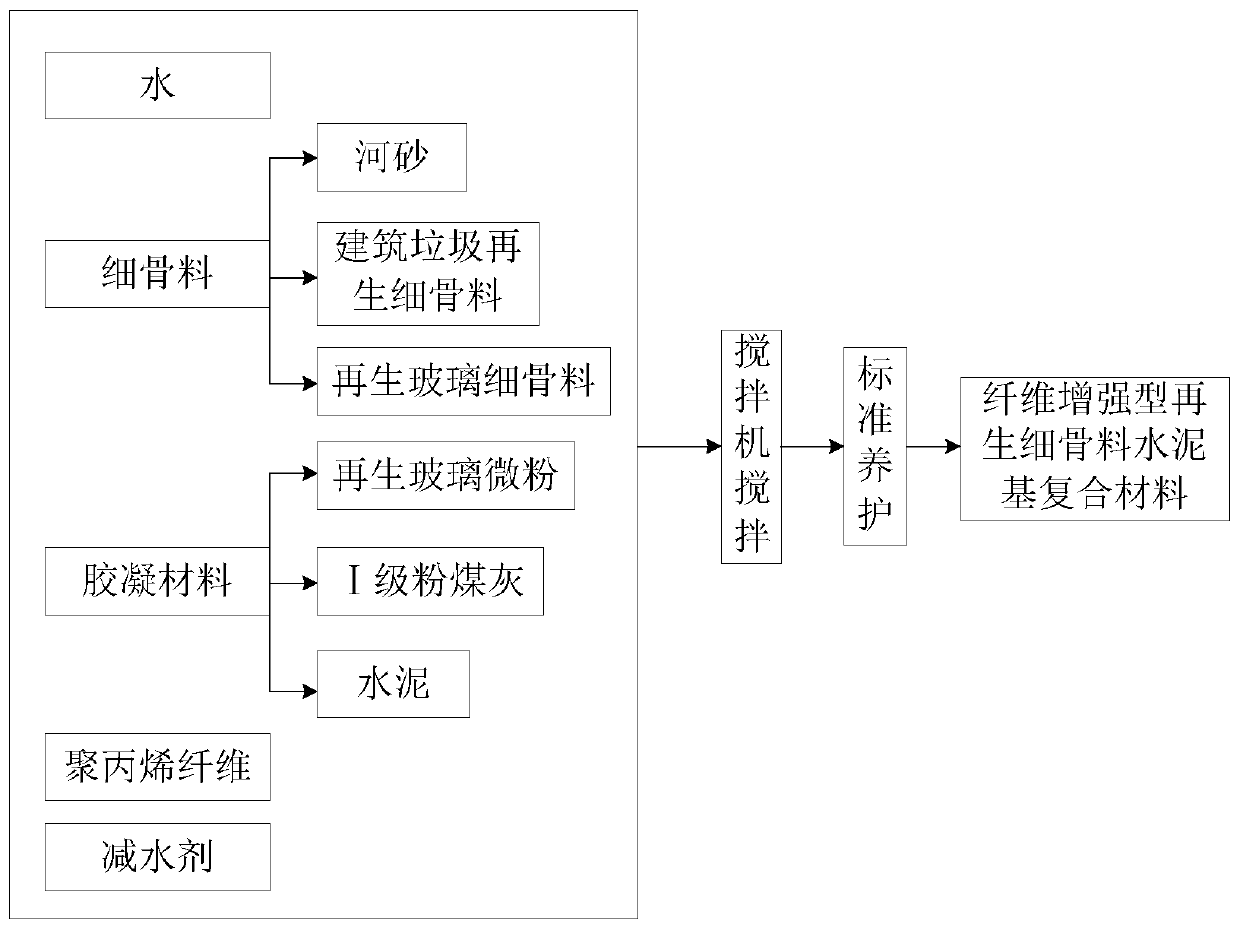

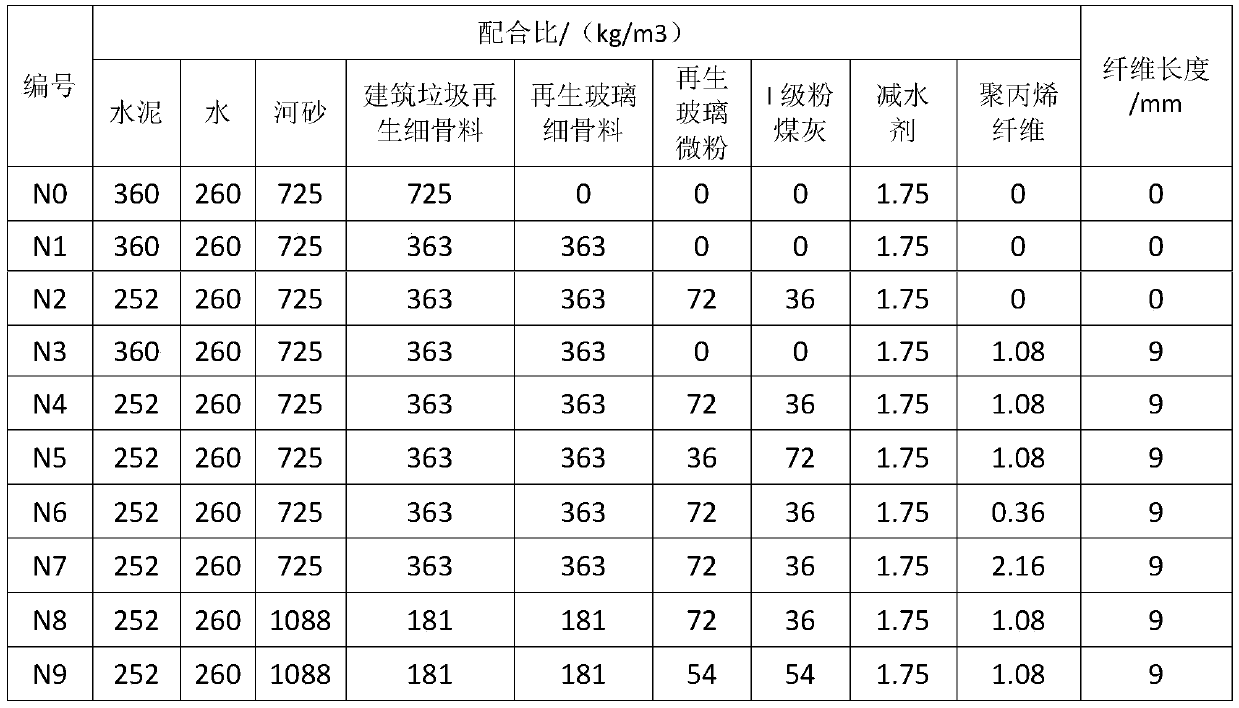

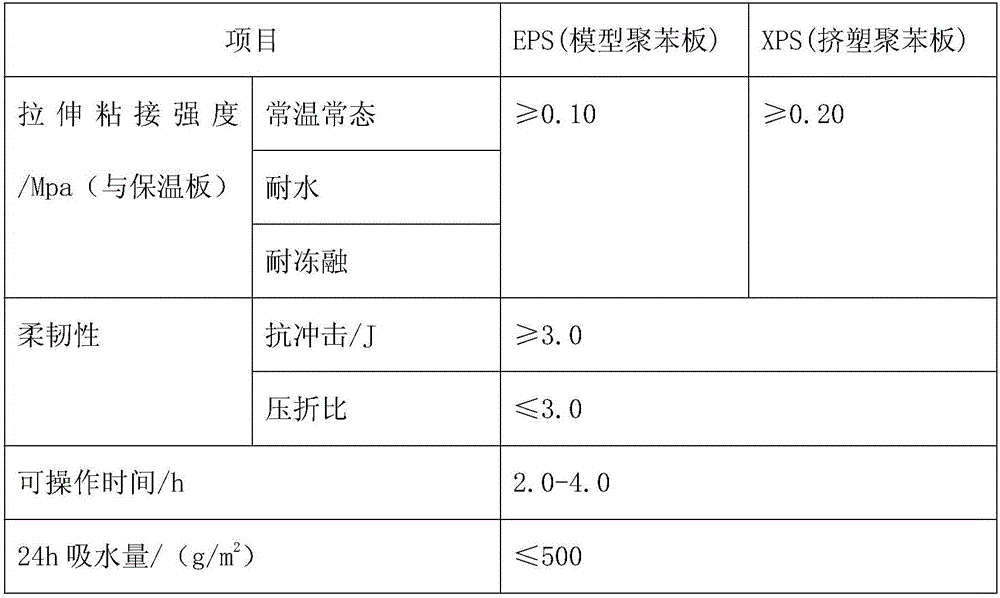

Fiber reinforced regenerated fine aggregate cement-based composite material

ActiveCN110498647AReduce dosageIncrease replacement rateSolid waste managementCrack resistanceShrinkage rate

The invention relates to a fiber reinforced regenerated fine aggregate cement-based composite material and a preparation method thereof. The composite material consists of water, a cementing material,a water reduction agent, a polypropylene fiber and a fine aggregate through mixing, wherein a water to glue ratio is 0.72; the mass ratio of the water to the cementing material to the fine aggregateis 1:1.38:5.58; the cementing material consists of cement, regenerated glass micro powder and grade-I coal ash; the cement accounts for 70% of the weight of the cementing material; the regenerated glass micro powder and the grade-I coal ash account for 30% of the weight of the cementing material in all; the regenerated glass micro powder accounts for 10-20% of the weight of the cementing material;the grade-I coal ash accounts for 10-20% of the weight of the cementing material; the water reduction agent accounts for 0.5% of the mass of the cementing material; the polypropylene fiber accounts for 0.1-0.6% of the mass of the cementing material; the fine aggregate consists of a regenerated fine aggregate and river sand; the regenerated fine aggregate accounts for 25-50% of the weight of the fine aggregate, and the balance is river sand; a construction waste regenerated fine aggregate accounts for 50% of the weight of the regenerated fine aggregate; and a regenerated glass fine aggregate accounts for 50% of the weight of the regenerated fine aggregate. By adopting the composite material, the cracking resistance can be improved, the compressive strength ratio and the shrinkage rate canbe reduced, and the freezing resistance can be improved.

Owner:NORTHEAST DIANLI UNIVERSITY

Dry-mixed thermal-insulation board finishing mortar and preparation method thereof

The invention discloses a dry-mixed thermal-insulation board finishing mortar which is prepared from the following raw materials in parts by weight: 80-100 parts of Portland cement, 10-20 parts of yellow sand, 5-8 parts of modified nano bamboo charcoal powder, 5-10 parts of talcum powder, 3-5 parts of desulfurized gypsum, 3-5 parts of limestone, 1-5 parts of cellulose ether, 5-15 parts of tree ash, 3-6 parts of wood fiber, 1-6 parts of naphthalene high efficiency water reducing agent salt, 6-10 parts of vinyl acetate-ethylene copolymer rubber powder and 2-4 parts of fumed silica. The dry-mixed thermal-insulation board finishing mortar has the advantages of favorable anti-crack durability, low fold ratio, low water absorptivity, small shrinkage, excellent bonding property with the thermal-insulation board, and high combination firmness with the interface; the formed finishing layer has the advantages of acid resistance, aging resistance, collision resistance, rain permeation resistance, crack resistance and the like; and the product has low density and low cost.

Owner:安庆市凯瑞建材有限公司

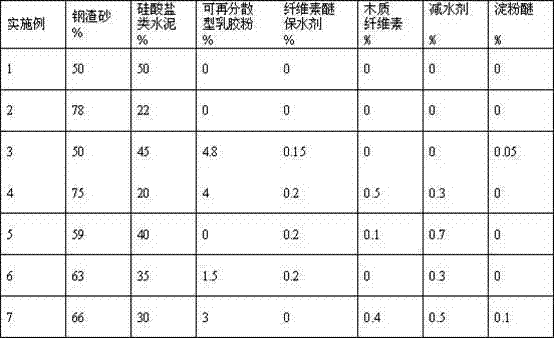

Cement-based steel slag sand mending material used for mending buildings

The invention provides a cement-based steel slag sand mending material used for mending buildings. Raw materials for the mending material comprise, by weight, 50 to 78% of steel slag sand with a particle size of no more than 4.75 mm and 22 to 50% of silicate cement. According to the invention, steel slag can be used to fully replace river sand, and the mending material prepared from the steel slag has better tensile bond strength than that of a mending material prepared from natural river sand. When a plurality of auxiliary materials are properly added, the mending material better presents the advantages of high bond strength, good flexibility, appropriate anti-compression and flexural strength, a low ratio of compressive strength to flexural strength, good wear resistance, good crack resistance, a small drying shrinkage value and good compatibility with a cement concrete material. According to the invention, the raw materials are widely available and cheap, and industrial waste, i.e., steel slag, is fully utilized; a product obtained after uniform mixing of the raw materials in proportion has stable quality and is simple to construct and operate on site; after mixed with water, the mending material provided by the invention has good workability and water retention performance and is nonhazardous, pollutionless, green, environment-friendly and energy saving mending mortar for buildings.

Owner:武钢集团有限公司

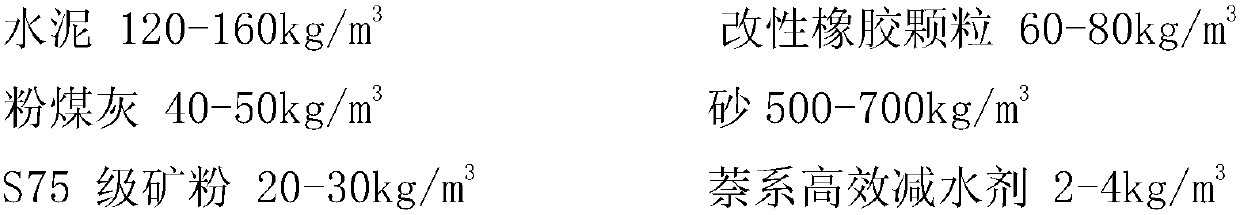

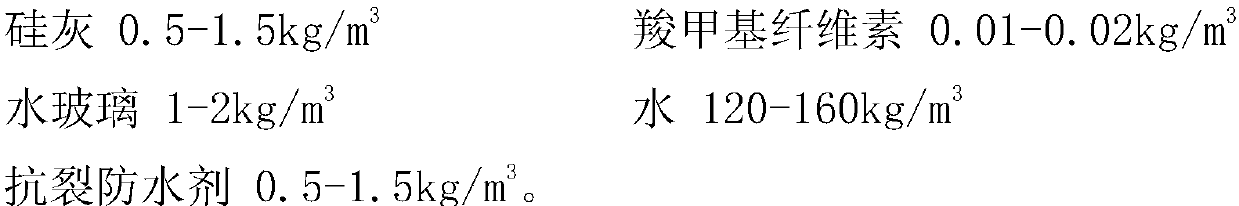

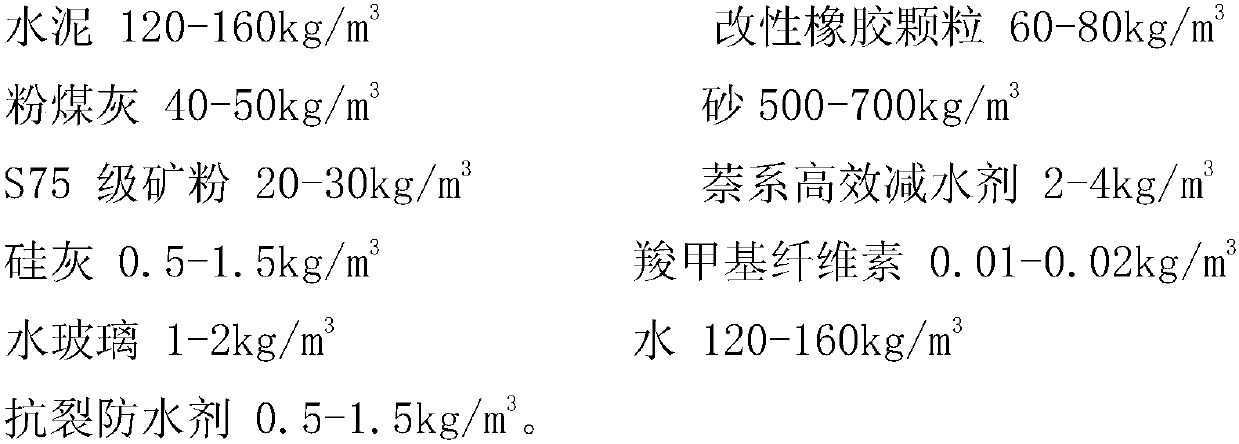

Method for preparing water-resistant thermal insulation mortar from modified rubber particles

The invention discloses a method for preparing water-resistant and heat-retaining mortar with modified rubber particles. The rubber particles are soaked in alkaline solution, rubbed, washed and filtered, and the hydrophobic surface layer is removed to present a rough surface, and then rinsed with clean water and dried. In a water bath environment, add the treated rubber particles and coupling modifier into a water bath container and stir, and obtain modified rubber particles after drying; weigh silica fume and anti-cracking waterproof agent, add water and stir evenly, then add water glass, Mix evenly; pour the prepared modified rubber particles into the above slurry and mix evenly for interface treatment, then cool the modified rubber particles that have been pretreated at the interface until half-dry, and set aside; mix cement, fly ash, After mixing sand, S75 grade mineral powder and modified rubber particles with interface pretreatment, stir in a concrete or mortar mixer; then add water, naphthalene-based high-efficiency water reducer and carboxymethyl cellulose and stir again to obtain Modified rubber particle water-resistant and thermal insulation mortar. The modified rubber particle mortar prepared by the invention has strong water resistance and thermal insulation.

Owner:上海涛瀚橡塑制品有限公司

Self-heat-preservation building block foam concrete material for fabricated steel structure building and preparation method thereof

PendingCN106518152AHigh softening coefficientHigh bonding strengthCeramicwareFoam concreteFlexural strength

The invention discloses a self-heat-preservation building block foam concrete material for a fabricated steel structure building and a preparation method thereof. The foam concrete material is prepared from, by weight, 100 parts of cement, 2-15 parts of rapid-hardening sulphoaluminate cement, 5-20 parts of active micro silicon powder, 2-10 parts of rubber powder, 2-8 parts of latex powder, 0-2 parts of polypropylene fibers, 0.2-1.5 parts of water repellent, 0.01-0.2 part of alkylbenzene sulfonate air-entraining agent, 0.1-2 parts of water reducing agent, 1.5-3 parts of foaming agent and 24-50 parts of water. The foam concrete material is specially designed according to needed characteristics of a self-heat-preservation building block core material or interlayer and has the advantages of being high in bonding strength, low in compressive strength-flexural strength ratio, low in heat conductivity coefficient and water absorption rate, good in durability, simple in production process, good in heat preservation and heat insulation performance, resistant to fire and the like, the shear deformation resistance of the foam concrete core material or interlayer is effectively enhanced, and the problems of shrinkage cracking, low bonding capacity, water seepage, inflammability and the like are relieved.

Owner:武汉钢铁有限公司

Sprayed concrete for roadway

The invention provides sprayed concrete for a roadway. The sprayed concrete is prepared from the following raw materials in parts by weight: 80-120 parts of cement, 40-60 parts of superfine aggregate, 80-100 parts of fine sand, 10-20 parts of fibers, 6-12 parts of rubber powder, 7-10 parts of nano aluminum oxide, 3-8 parts of polyacrylamide, 8-14 parts of an MK-1 reinforcing agent, 1.5-5 parts of a water reducing agent, 6-10 parts of a flame retardant and 10-18 parts of an accelerator. According to the invention, an inorganic-organic co-hybrid polymer dispersion group system is formed on the basis of the principle of an inorganic-organic ultrafine powder assembly, coating and dispersion system, so that moderate toughness and rigidity can be achieved, excellent guniting material indexes such as high adhesion, cracking resistance, impermeability, reinforcement and support and the like are achieved, and the concrete also has relatively strong toughness, ductility, heat insulation and shock absorption performance.

Owner:河南省宜居建材科技有限公司

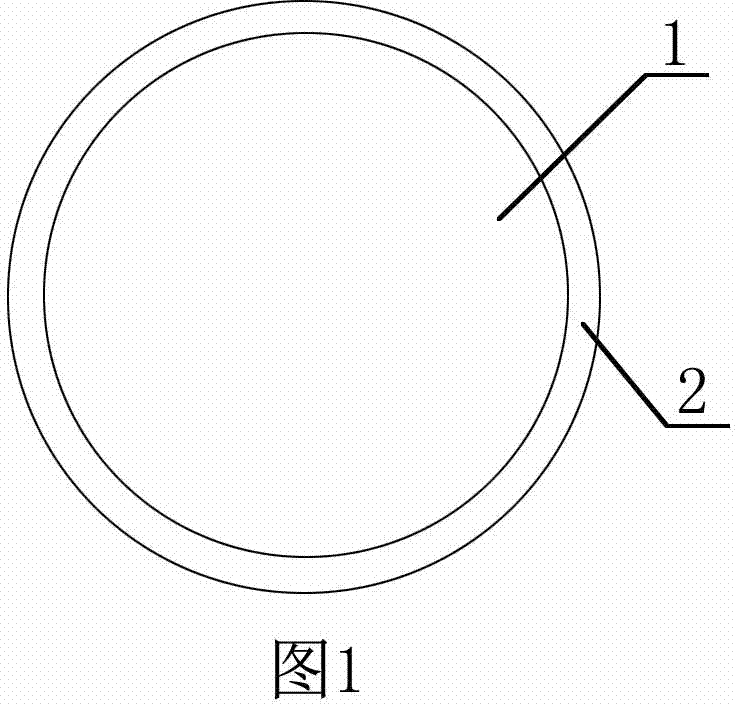

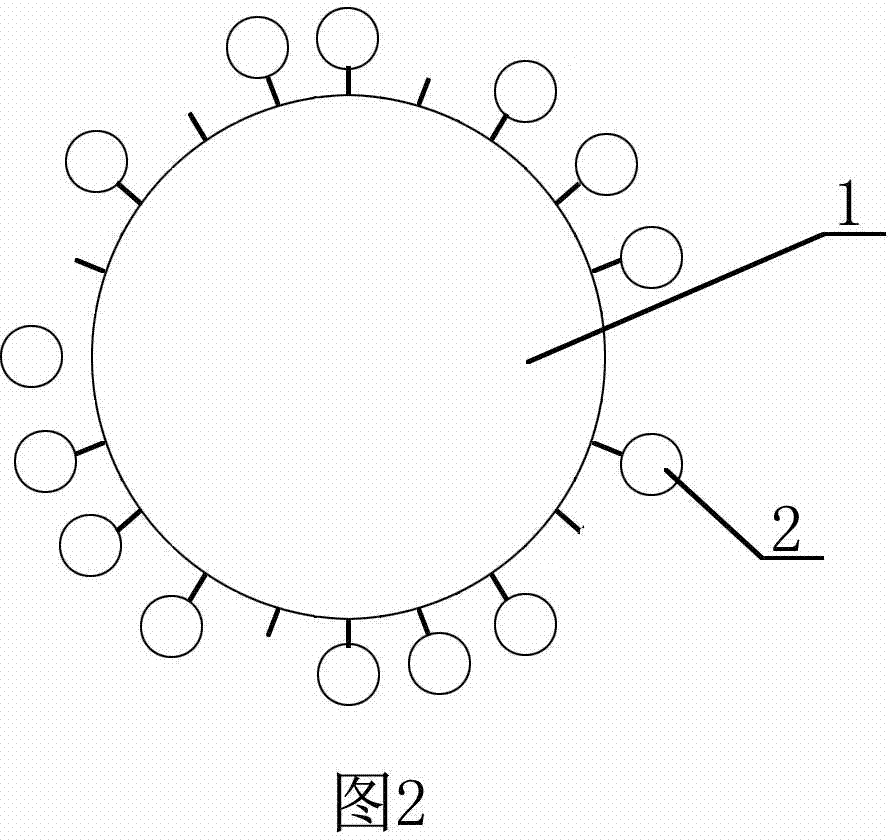

Composite phase-change energy storage interior thermal insulation mortar of heliogreenhouse wall and preparation method thereof

ActiveCN108298935AHigh water retentionHigh heat storage coefficientThermal insulationMaterials science

The invention belongs to the technical field of building function materials, and discloses energy-saving composite phase-change energy storage interior thermal insulation mortar of heliogreenhouse wall and a preparation method thereof. The thermal insulation mortar is the mixture prepared from raw material dry powder and water which accounts for 70%-110% of the total weight of the raw material dry powder, and the raw material dry powder takes building flue gas desulfurization gypsum as a cementing material and is prepared from light composite shape-stabled phase change particles, redispersible powder, citric acid, hydroxypropyl methyl cellulose ether, polypropylene fiber and the like. The composite phase-change energy storage interior thermal insulation mortar is used for heat preservation inside the heliogreenhouse wall, the effects of better heat preservation and heat storage and heat release can be achieved, the thermal environment inside a heliogreenhouse is improved, and the growth efficiency of crops in a greenhouse can be improved, thereby g the production benefits of the greenhouse is improved.

Owner:HEZE UNIV

Rubber aggregate dry-mixed mortar

The invention relates to a rubber aggregate dry-powder mortar, belonging to the technical field of novel construction material. In the construction energy-conserving field, the outer-wall external insulation technique is adopted as the main technique for the outer envelope insulation of energy-conserving constructions is a common consensus, but the system requires a large energy and sources. The invention aims at exploiting a second source technique, namely, the waste rubber aggregate dry-powder mortar which is formed by evenly mixing waste rubber aggregate, cement, sand, RPP, wood fiber and methyl cellulose, and the matching proportions of the materials by weight portion are as follows: 1 portion of cement, 0.25 to 1.75 portions of sand, 0.6 to 0.9 portion of water, 0.04 to 0.15 portion of RPP, 0 to 0.018 portion of wood fiber and 0 to 0.016 portion of methyl cellulose and 0.27 to 0.83 portion of rubber aggregate. The invention has excellent work capability and construction capability and not only can reach better insulation effect but can realize better economic benefit, and the construction energy-conserving effect is distinct.

Owner:BEIJING UNIV OF TECH

Modified rubber particles for mortar and preparation method of modified rubber particles

Disclosed are modified rubber particles for mortar and a preparation method of the modified rubber particles. The preparation method includes soaking rubber particles in alkali liquor; removing hydrophobic surface layers of the rubber particles so that rough surfaces of the rubber particles are exposed; washing the rubber particles by clear water; adding the treated rubber particles and a coupling modifier into a water bath container to stir the treated rubber particles and the coupling modifier under a water bath environment at the temperature ranging from 40 DEG C to 70 DEG C after the rubber particles are dried; and drying the mixture in the water bath container to obtain the modified rubber particles. The modified rubber particles for mortar and the preparation method have the advantages that affinity of the rubber particles and mortar is obviously enhanced by means of modification, cracking and pull strength of the mortar are improved, the ratio of compressive strength of mortar materials is reduced, and the modified rubber particles can be used as anti-crack components in the mortar in a building project. In addition, the surfaces of the rubber particles are corroded by the aid of alkali liquor treatment, the specific surface area is increased, accordingly, bonding with a coupling agent is enhanced, a modification effect is improved, and shearing force of the modified rubber particles and the mortar is increased.

Owner:北京振利节能环保科技股份有限公司

Production method of foam cement

InactiveCN105016772ASimilar flexural strengthDecreased flexural strengthCeramicwarePolyvinyl alcoholFlexural strength

The invention discloses a production method of foam cement including the components: 42.5-grade ordinary portland cement, 30% hydrogen peroxide, sodium nitrite, calcium oxide, sodium chloride, an aluminum powder, sodium thiosulfate, an iron powder, nekal, tartaric acid, triisopropanolamine, ammonium chloride, rosin, bone glue, sodium hydroxide, gypsum, sodium carbonate, a 5% polyvinyl alcohol solution and water with the mass ratio of 1000:21.3:14.2:14.2:14.2:0.01:2.5:1.1:0.5:0.3:3:1.3:2.1:0.14:1.5:1.9:0.1:0.6:238; concrete prepared from the foam cement has the bending tensile strength and stiffness similar to those of ordinary cement concrete, has the ratio of compressive strength to flexural strength decreased compared with ordinary foamed concrete; and the formula saves 20%-30% of cement than ordinary foam cement.

Owner:TONGLING HAIYUAN SUPERFINE POWDER

Single-component high-performance mortar for repairing and reinforcing concrete

The invention provides single-component t high-performance mortar for repairing and reinforcing concrete, which comprises the following components in part by mass: 200g of sand, 55 to 75 parts of ordinary portland cement, 10 to 30 parts of sulphate aluminium cement, 3 to 7 parts of siliceous dust, 8 to 12 parts of flyash, 0.18 to 0.22 part of water reducing agent, 2 to 4 parts of flexibilizer, 0.04 to 0.06 part of water-retaining agent, 1.0 to 2.0 parts of swelling agent and 0.1 to 0.2 part of polymer synthetic fiber. The single-component t high-performance mortar has the advantages of high initial strength, good adhesion, excellent cracking resistance, low ratio of compressive strength to flexural strength, excellent toughness, simple and convenient construction, single component, no toxin or smell, no harm to human bodies, and environmental protection without pollution.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

A kind of anti-cracking thermal insulation wall building material and preparation method thereof

Owner:MAANSHAN TIANJINYUN PAINT IND

Preparation method of hydrophobic mortar

InactiveCN111056802ADoes not affect breathabilityReduce brittlenessWater leakageArchitectural engineering

The cement mortar is a main construction material in the construction industry, but the problem of water leakage is difficult to solve when cement concrete and cement mortar are used, and various measures are adopted in engineering in order to prevent the water leakage phenomenon in cement buildings. One of the methods is a method for adding an admixture into a cement building material. The heat preservation and insulation building built through the method is not cold in winter and not hot in summer indoors, the living environment is greatly improved, energy is saved, various indexes, especially the hydrophobicity index, are located at the domestic advanced level, and obvious social benefits and economic benefits are achieved.

Owner:江苏瓦楷新材料科技有限公司

Dry-mixed mortar for pavement and preparation process thereof

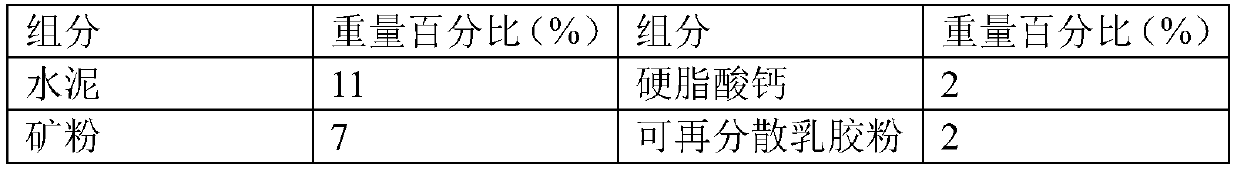

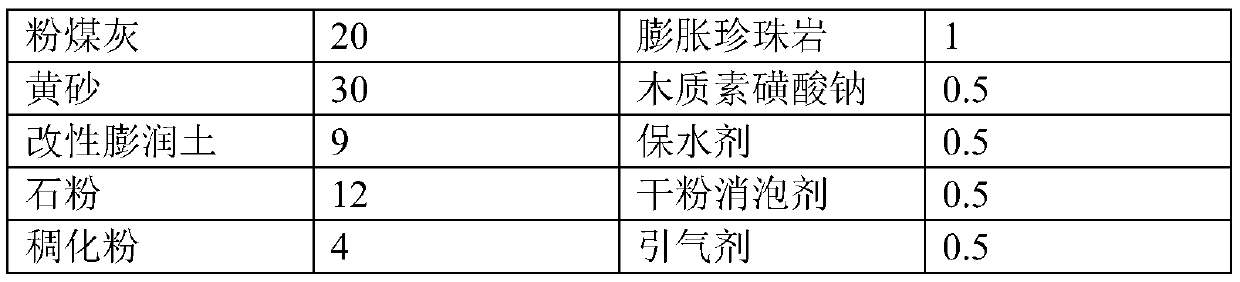

The invention relates to dry-mixed mortar for a pavement and a preparation process of the dry-mixed mortar. The invention relates to the technical field of building materials. The dry-mixed mortar specifically comprises the following components in percentage by weight: 11-13% of cement, 6-8% of mineral powder, 17-20.5% of fly ash, 26-33% of yellow sand, 9-11% of modified bentonite, 10-13% of stonepowder, 2.5-4% of thickening powder, 1-2% of waterproof agent, 1-2.5% of redispersible latex powder, 1-2% of expanded perlite and 1.5-3% of an additive. The preparation method of the modified bentonite is as follows: 1) adding 20-30kg of glucose into 300-400L of water and stirring until the glucose is completely dissolved; 2) continuously adding 100-120 kg of bentonite and continuously stirring to uniformly disperse the bentonite; 3) adjusting the pH to 12-13, then raising the temperature to 80-120 deg c, stirring for 4-6 hours, centrifuging after stirring, washing the precipitate with waterfor 3-5 times, and drying. The mortar prepared by the method has the effects of good wear resistance, long service life of the pavement and reduction of maintenance cost of the pavement when laid on the pavement.

Owner:宁波新广亿建材有限公司

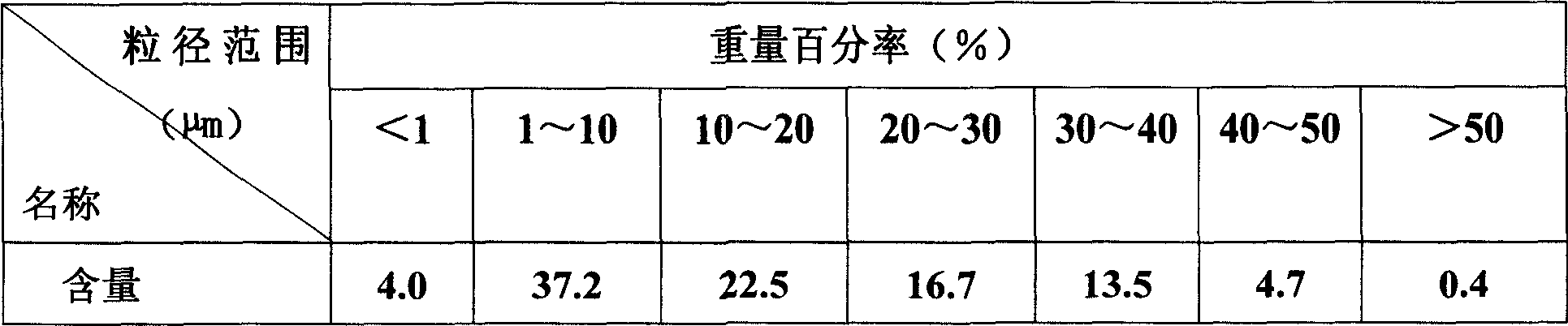

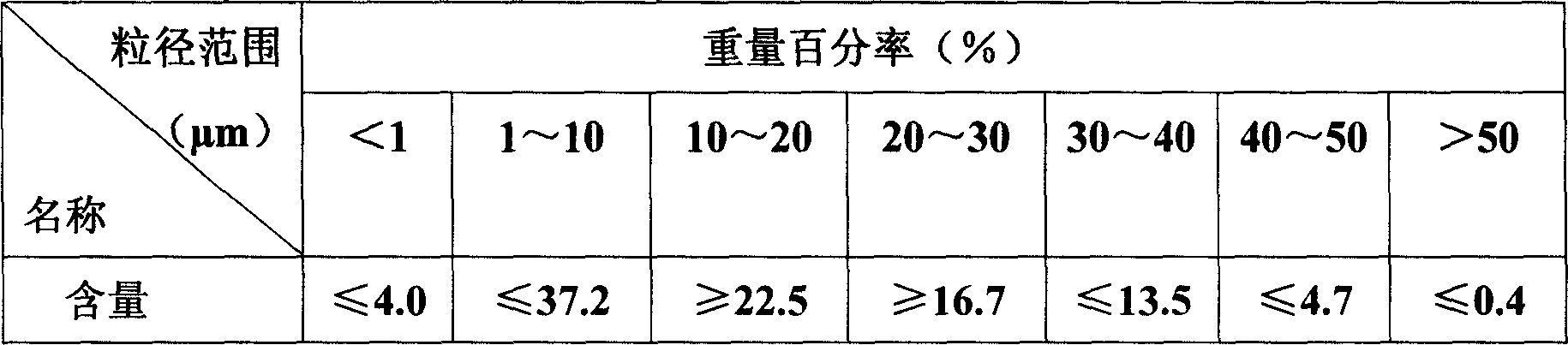

Outer-wall external thermal-insulation anti-crack mortar prepared from superfine sand

The invention discloses an outer-wall external thermal-insulation anti-crack mortar prepared from superfine sand. The outer-wall external thermal-insulation anti-crack mortar consists of the following ingredients in parts by weight: 25-35 parts of cement, 62-72 parts of superfine sand with fineness modulus of 0.5-0.6, 1.0-3.0 parts of shrinkage reducing agent, 0.2-0.4 part of polymer modifier, 0.1-0.3 part of water-retaining agent, and 0.05-0.15 part of fiber. When the outer-wall external thermal-insulation anti-crack mortar is in use, all the ingredients are mixed with water added in a certain ratio as required on site and are stirred uniformly. Proven by experiments, the outer-wall external thermal-insulation anti-crack mortar has the advantage of solving the technical problems such as serious shrinkage and poor construction performance obstructing the use of the superfine sand with fineness modulus of 0.5-0.6 in the anti-crack mortar; and the anti-crack mortar with the ratio of compressive strength reaching 1.90, the bonding strength reaching 1.0MPa and long operational time reaching 2h is prepared and the anti-crack mortar meets the technical requirements of JG158-2004 ETIRS (external thermal insulation rendering systems made of mortar with mineral binder and nsing wxpanded polystyrene granule as aggregate) on the anti-crack mortar.

Owner:重庆钰居环保科技有限公司

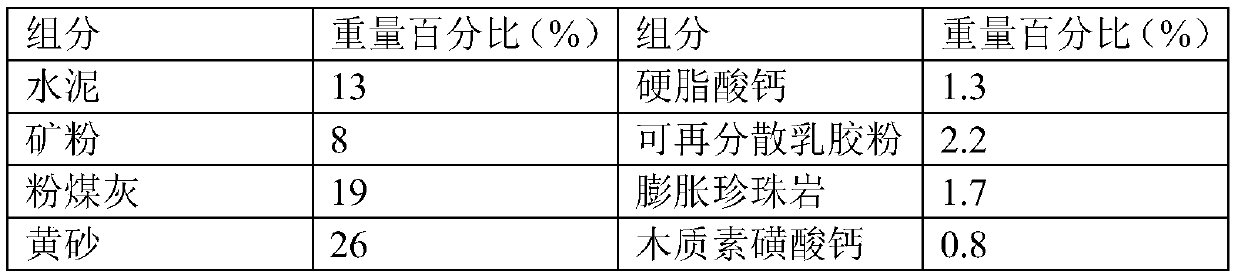

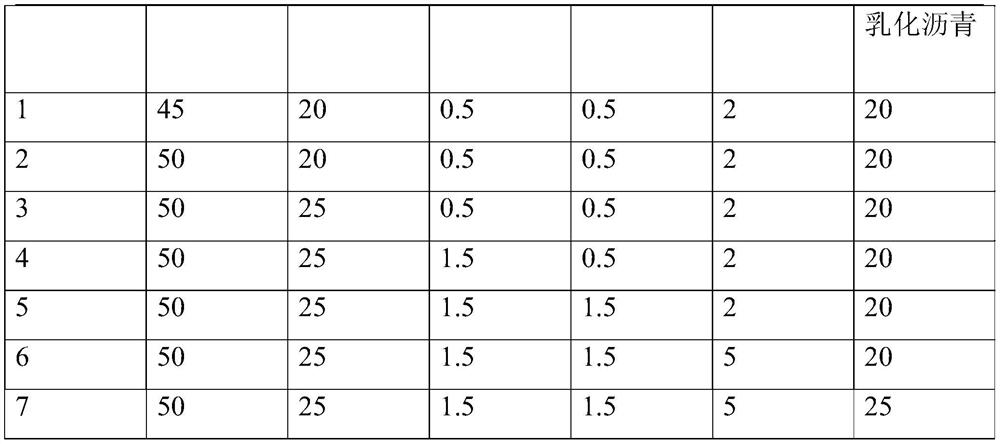

Adhesive cement material for repairing hidden spalling of asphalt pavement and preparation method of adhesive cement material

InactiveCN114180908ACounteract shrinkage stressReduce shrinkage cracksSolid waste managementAdhesive cementEpoxy

The invention discloses a mucilage material for repairing hidden spalling of an asphalt pavement and a preparation method of the mucilage material. The mucilage material comprises the following components in parts by weight: 45-50 parts of cement; 20 to 25 parts of water; 20 to 25 parts of waterborne epoxy emulsified asphalt; 2-5 parts of nano silica fume; 0.5 to 1.5 parts of an expanding agent; and 0.5-1 part of a water reducing agent. The adhesive cement material has high permeability, high bonding strength and hydrophilicity, can react with moisture in recessive spalling to generate cement gel so as to increase the bonding strength between the cement adhesive cement and a base material, has higher breaking strength, can have better deformation coordination with the base material, and can be used for preparing the cement adhesive cement. In addition, the adhesive cement material has the micro-expansion characteristic and toughness, pores of a base material can be better filled, meanwhile, brittle cracking is reduced, and finally the pavement performance and the service life of the hidden peeling position of the asphalt pavement are improved and prolonged.

Owner:中铁建公路运营有限公司 +1

Micro pile mortar admixture

The invention discloses a micro pile mortar admixture which is used for preventing mortar from corrosion due to environment interferences and preventing the mortar from cracking in a hardening process and cracking in a using process. The admixture comprises the following components in percentage by weight (based on the dosage of cement): 0.2%-0.5% of polypropylene fiber, 0.5%-1% of coal ash, 0.3%-1.5% of FDN naphthalene-series efficient water reducing agent and 1%-3% of U type expanding agent, which are used as a mixing type additive for mixing pile body mortar, wherein the mixing amount is 2%-5% of the dosage of the cement.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Semi-flexible pavement cement-based adhesive cement composition and preparation method thereof

The invention provides a semi-flexible pavement cement-based adhesive cement composition and a preparation method thereof, and belongs to the technical field of pavement materials, the semi-flexible pavement cement-based adhesive cement composition is prepared from the following raw materials by weight: 100-120 parts of cement, 20-30 parts of inorganic nano hollow particles, 5-30 parts of quartz sand, 1-5 parts of a polymer emulsion, 0.1-1 part of a thixotropic agent, 0.1-2 parts of an antifoaming agent, 0.1-0.7 part of an expanding agent and 150-200 parts of water; the particle size of the quartz sand is 0.5-2 mm; and the cement is 42.5 sulphoaluminate cement. The semi-flexible pavement cement-based adhesive cement disclosed by the invention is good in fluidity, good in rheological property of a whole system, relatively good in mechanical property, good in high-temperature rutting resistance, low-temperature cracking resistance, water damage resistance and fatigue resistance, and capable of prolonging the service life of a pavement.

Owner:广东省湛江公路工程大队

Modified expansion water-stop mortar and preparation method thereof

ActiveCN102674779BGood construction performanceReduce manufacturing costSolid waste managementCellulosePliability

The invention discloses modified expansion water-stop mortar and a preparation method thereof. The modified expansion water-stop mortar comprises the following raw materials in percentage by weight: 25 to 50 percent of sulphoaluminate cement, 40 to 60 percent of quartz sand, 3 to 5 percent of redispersible rubber powder, 0.1 to 0.3 percent of cellulose ether, 0.3 to 1 percent of calcium stearate and 5 to 10 percent of composite lightweight aggregate, wherein the composite lightweight aggregate is mixture of waste polyurethane particles and rubber particles; and the weight ratio of the waste polyurethane particles to the rubber particles is (10-30):(70-90). The flexibility and elasticity of the expansion water-stop mortar are improved obviously, the construction performance of the mortar is improved, the ratio of compressive strength of a cementing material is reduced, and the elastic modulus of the material is reduced. When the modified expansion water-stop mortar is used during construction, harmful fissures which are caused by the change of temperature and humidity, vibration and the like can be reduced, and the waterproofing and anti-permeability capacities of the motor are improved. The expansion water-stop mortar is particularly suitable for waterproofing treatment of openings and eavesprojection structures of doors and windows in construction engineering.

Owner:北京振利节能环保科技股份有限公司

Rapid repair mortar for partial damage of concrete base and preparation method thereof

The invention relates to a quick repair mortar for locally damaged concrete base and a preparation method thereof, which is characterized in that it comprises the following raw materials in parts by weight: 50-70 parts of aggregate, 20-30 parts of composite cement, and 4-8 parts of styrene-butadiene emulsion , 1-3 parts of coupling agent, 0.5-2 parts of composite shrinkage reducing agent, 0.1-0.5 parts of water-repellent agent, 0.1-0.5 parts of graphene dispersion, 0.1-0.5 parts of polypropylene fiber; the composite cement includes fluoroaluminate Cement and aluminate cement, the mass ratio of fluoroaluminate cement and aluminate cement is 2-3:1, the aggregate adopts natural sand, and the particle size of natural sand is 30-120 mesh, wherein, 30‑50 mesh accounts for 15%, 51‑80 mesh accounts for 55%, and 81‑120 mesh accounts for 30%. The invention adjusts the formula and proportion, mixes various trace additives, improves the pore structure of the mortar matrix, increases the compactness of the mortar, improves the construction performance and shrinkage performance of the repaired concrete, and the strength develops in a relatively short time after pouring Quickly meet the application requirements of local rapid repair of concrete base.

Owner:GUANGXI POLYTECHNIC VOCATIONAL & TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com