Micro pile mortar admixture

An admixture and micro-pile technology, which is applied in the field of geotechnical engineering, can solve problems such as micro-pile structural failure, passivation film damage, and protective layer damage, achieving significant economic benefits, cost savings, and improving compression and flexural resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Component according to the amount of cement: polypropylene fiber 0.2%, fly ash 0.5%, FDN naphthalene series superplasticizer 0.3%, U-type expansion agent 1%.

[0014] The mixing amount is 2% of the cement amount.

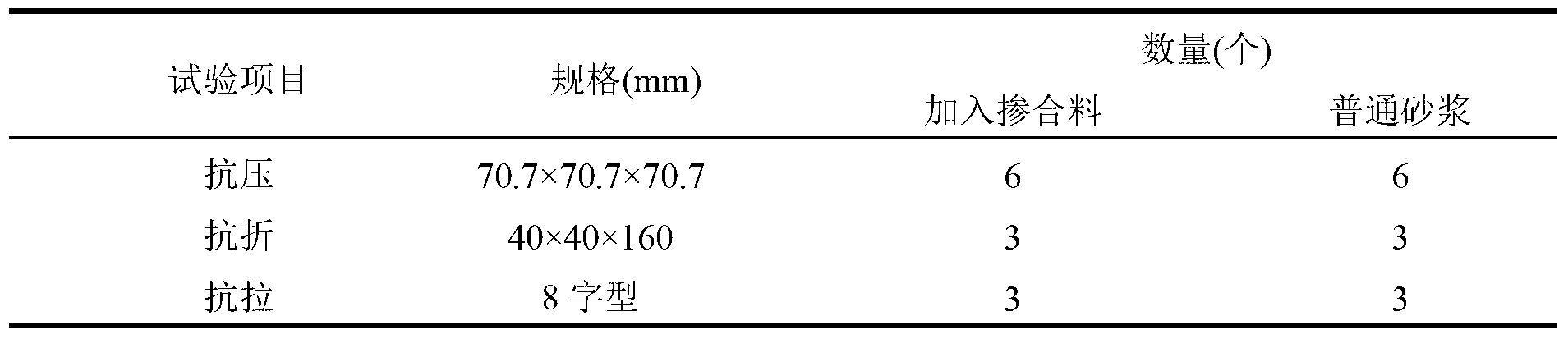

[0015] Table 1 Mechanics test items

[0016]

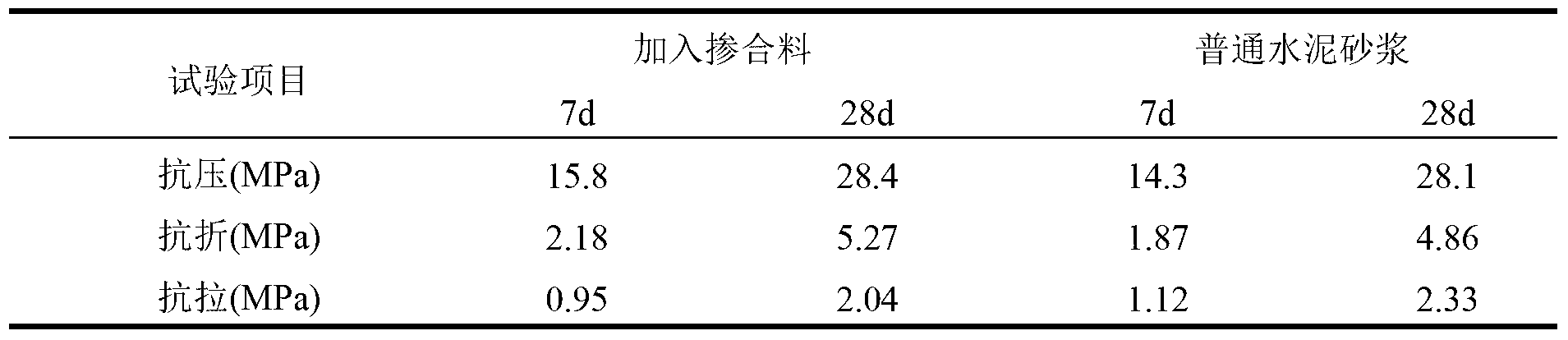

[0017] Table 2 Test results

[0018]

Embodiment 2

[0020] Component according to the amount of cement: polypropylene fiber 0.5%, fly ash 1%, FDN naphthalene series superplasticizer 0.5%, U-type expansion agent 3%.

[0021] The mixing amount is 5% of the cement amount.

[0022] Table 3 Mechanical test items

[0023]

[0024] Table 4 Test results

[0025]

Embodiment 3

[0027] Component according to the amount of cement: polypropylene fiber 0.28%, fly ash 0.75%, superplasticizer 0.43%, expansion agent 2.04%.

[0028] The mixing amount is 3.5% of the cement amount.

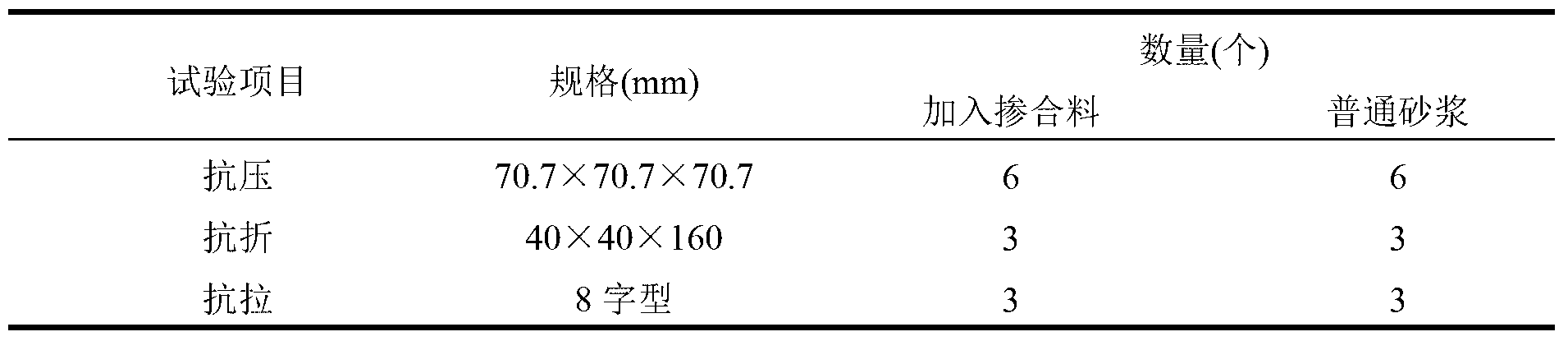

[0029] Table 5 Mechanical test items

[0030]

[0031] Table 6 Test results

[0032]

[0033] It can be seen from Tables 1 to 6 that among the various indexes of cement mortar 7d and 28d with admixtures, except for some of the 7d tensile indexes which are slightly lower than ordinary cement mortar, the others are all higher than ordinary cement mortar to varying degrees. In Example 3, the compressive and flexural indexes of 7d were 20.27% and 73.79% higher than those of ordinary cement mortar, and the tensile strength was slightly lower by 5.36%; the 3 indexes of 28d were 4.27%, 40.53% and 19.74% higher respectively. It shows that adding MPC-I type anti-corrosion additives to cement mortar can greatly improve the compressive and flexural properties of cement mortar, and it can improve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com