Modified expansion water-stop mortar and preparation method thereof

A technology for expanding water-stopping and mortar, which is applied in the field of water-stopping mortar, can solve the problems of poor toughness, low ultimate tensile strength, and poor crack resistance of rigid water-stopping mortar, so as to improve construction performance, be beneficial to environmental protection, and improve flexibility. Effects of Sex and Elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

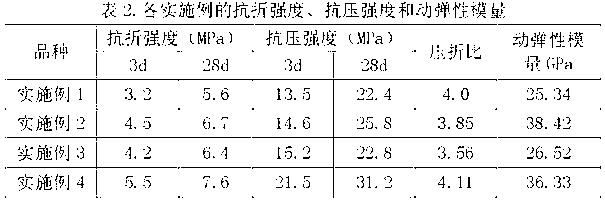

Examples

Embodiment 1

[0028] Embodiment 1, this modified expansion waterproof mortar, its raw material composition and weight percentage ratio are as follows:

[0029] Sulphoaluminate cement 25%;

[0030] Quartz sand 60%;

[0031] Redispersible rubber powder 5%;

[0034] Composite light aggregate 9.6%;

[0035] The composite light aggregate is a mixture of waste polyurethane particles and rubber particles, and the weight ratio of the two is 10:90.

Embodiment 2

[0036] Embodiment 2, this modified expansion waterproof mortar, its raw material composition and weight percentage ratio are as follows:

[0037] Sulphoaluminate cement 30%;

[0038] Quartz sand 60%;

[0039] Redispersible rubber powder 4.6%;

[0042] Composite light aggregate 5%;

[0043] The composite light aggregate is a mixture of waste polyurethane particles and rubber particles, and the weight ratio of the two is 20:80.

Embodiment 3

[0044] Embodiment 3, this modified expansion waterproof mortar, its raw material composition and weight percentage ratio are as follows:

[0045] Sulphoaluminate cement 40%;

[0046] Quartz sand 46%;

[0047] Redispersible rubber powder 3.6%;

[0048] Cellulose ether 0.1%;

[0049] Calcium stearate 0.3%;

[0050] Composite light aggregate 10%;

[0051] The composite light aggregate is a mixture of waste polyurethane particles and rubber particles, and the weight ratio of the two is 20:80.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com