Semi-flexible pavement cement-based adhesive cement composition and preparation method thereof

A semi-flexible pavement, cement-based technology, applied in the field of pavement materials, can solve problems such as incompleteness, and achieve the effects of prolonging service life, good fluidity, and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

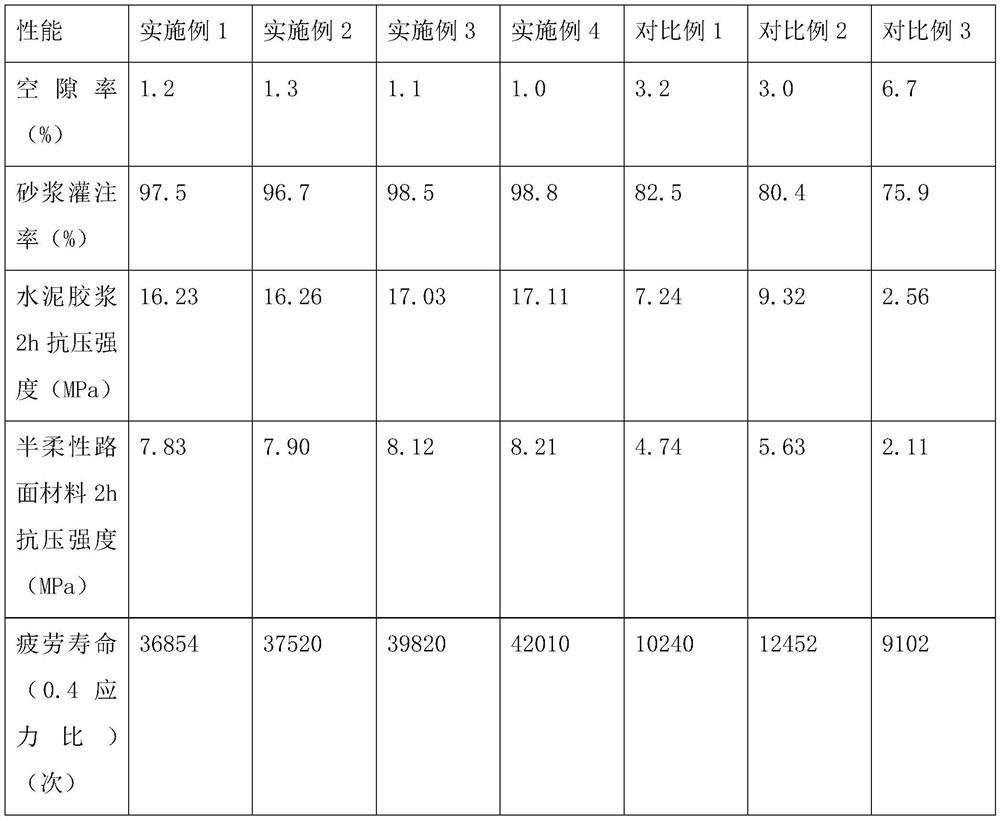

Examples

preparation example 1

[0033] Preparation Example 1 Inorganic Nano Hollow Particles

[0034] The preparation method is as follows:

[0035] S1. Add 100g Al(O-iC 3 h 7 ) 3 Dissolve 200g of methyl orthosilicate in chloroform, add 2g of composite coupling agent, stir and mix evenly to obtain an oil phase; the composite coupling agent is a combination of silane coupling agent KH560 and aluminate coupling agent DL-411 Mixture, the mass ratio is 1:2;

[0036] S2. Dissolving 1 g of porogen sorbitan fatty acid ester in water to obtain an aqueous phase;

[0037] S3. Add the oil phase into the water phase, emulsify for 2 min at 10000 r / min to obtain an emulsion, filter with suction, and dry at 100° C. for 2 h to obtain hollow inorganic nanoparticles.

preparation example 2

[0038] Preparation Example 2 Inorganic Nano Hollow Particles

[0039] The preparation method is as follows:

[0040] S1. Add 100g Al(O-sC 4 h 9 ) 3 Dissolve 300g tetraethyl orthosilicate in dichloromethane, add 10g composite coupling agent, stir and mix evenly to obtain oil phase; composite coupling agent is silane coupling agent KH590 and aluminate coupling agent DL-411 Mixture, the mass ratio is 1:3;

[0041] S2. Dissolving 5 g of the porogen polyethylene glycol octylphenyl ether in water to obtain an aqueous phase;

[0042] S3. Add the oil phase into the water phase, emulsify at 20000r / min for 4min to obtain an emulsion, filter it with suction, and dry at 120°C for 4h to obtain hollow inorganic nanoparticles.

preparation example 3

[0055] Preparation Example 3 Polymer Emulsion

[0056] Preparation method: Weigh 100g methacrylic acid, 50g butyl acrylate, 20g acrylic acid and mix evenly, then slowly add 1g Tween-80, 2gNaHCO 3 , the mixing system of 5wt% polyvinyl alcohol solution (containing polyvinyl alcohol 15g) and distilled water, with 300r / min rotating speed pre-emulsification 30min, emulsion is warmed up to 75 ℃, adds 2wt% initiator potassium persulfate solution (containing initiator Potassium persulfate 0.5g), stirred slowly for 1h to obtain a polymer emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com