Dry-mixed thermal-insulation board finishing mortar and preparation method thereof

A technology for plastering mortar and thermal insulation board, applied in the field of building materials, can solve the problems of low water retention rate and cohesion of mortar, easy shelling and cracking of mortar, low crack resistance, etc., and achieves low water absorption, excellent adhesion, and improved Effects of compressive strength and weatherability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

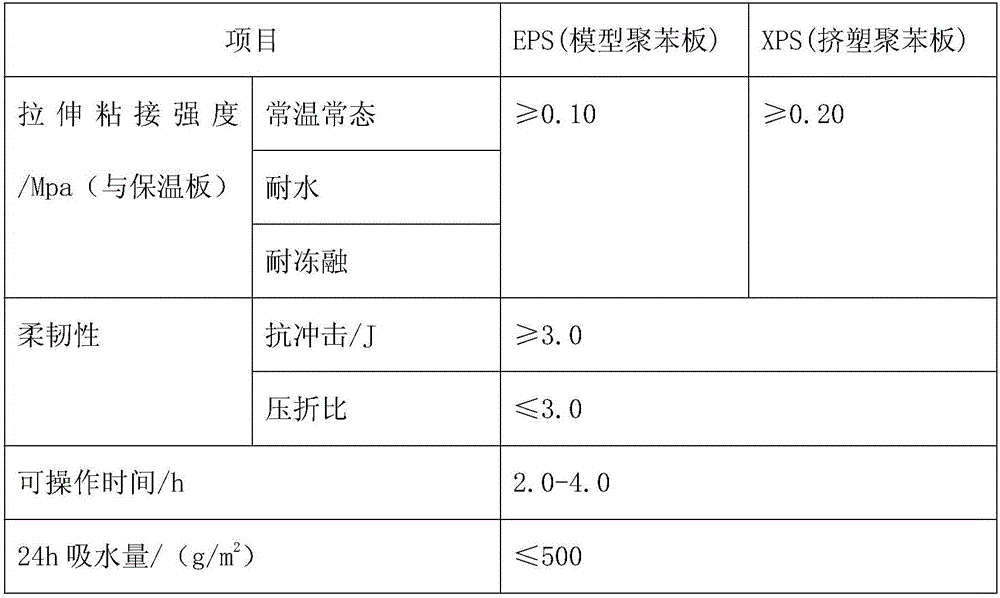

Image

Examples

Embodiment 1

[0016] A dry-mixed insulation board plastering mortar, made from the following raw materials in parts by weight: 80 parts of Portland cement, 20 parts of yellow sand, 5 parts of modified nano-bamboo charcoal powder, 8 parts of talcum powder, 3 parts of desulfurized gypsum, and 5 parts of limestone , 2 parts of cellulose ether, 6 parts of tree ash, 5 parts of wood fiber, 5 parts of Nai superplasticizer salt, 6 parts of vinyl acetate and ethylene copolymer powder, and 3 parts of fumed silica.

[0017] The modified nano-bamboo charcoal powder is prepared by the following method: soak the bamboo charcoal powder with 12% sodium hydroxide solution for 3 hours, then wash with deionized water, dry, and then add sodium laurate alkylate equivalent to 2% of its weight , 3% ethyl cyanoacrylate and 1% cross-linking agent TAC, stirred at 3500 rpm for 30 minutes, dried, and ground into nano powder.

[0018] The preparation method of the dry-mixed insulation board plastering mortar comprises ...

Embodiment 2

[0024] A dry-mixed insulation board plastering mortar, made of the following raw materials in parts by weight: 100 parts of Portland cement, 10 parts of yellow sand, 8 parts of modified nano-bamboo charcoal powder, 10 parts of talcum powder, 5 parts of desulfurized gypsum, and 3 parts of limestone , 5 parts of cellulose ether, 10 parts of tree ash, 6 parts of wood fiber, 6 parts of Nai superplasticizer salt, 6 parts of vinyl acetate and ethylene copolymer rubber powder, and 4 parts of fumed silica.

[0025] The modified nano-bamboo charcoal powder is prepared by the following method: soak the bamboo charcoal powder with 12% sodium hydroxide solution for 3 hours, then wash with deionized water, dry, and then add sodium laurate alkylate equivalent to 2% of its weight , 3% ethyl cyanoacrylate and 1% cross-linking agent TAC, stirred at 3500 rpm for 30 minutes, dried, and ground into nano powder.

[0026] The preparation method of the dry-mixed insulation board plastering mortar co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com