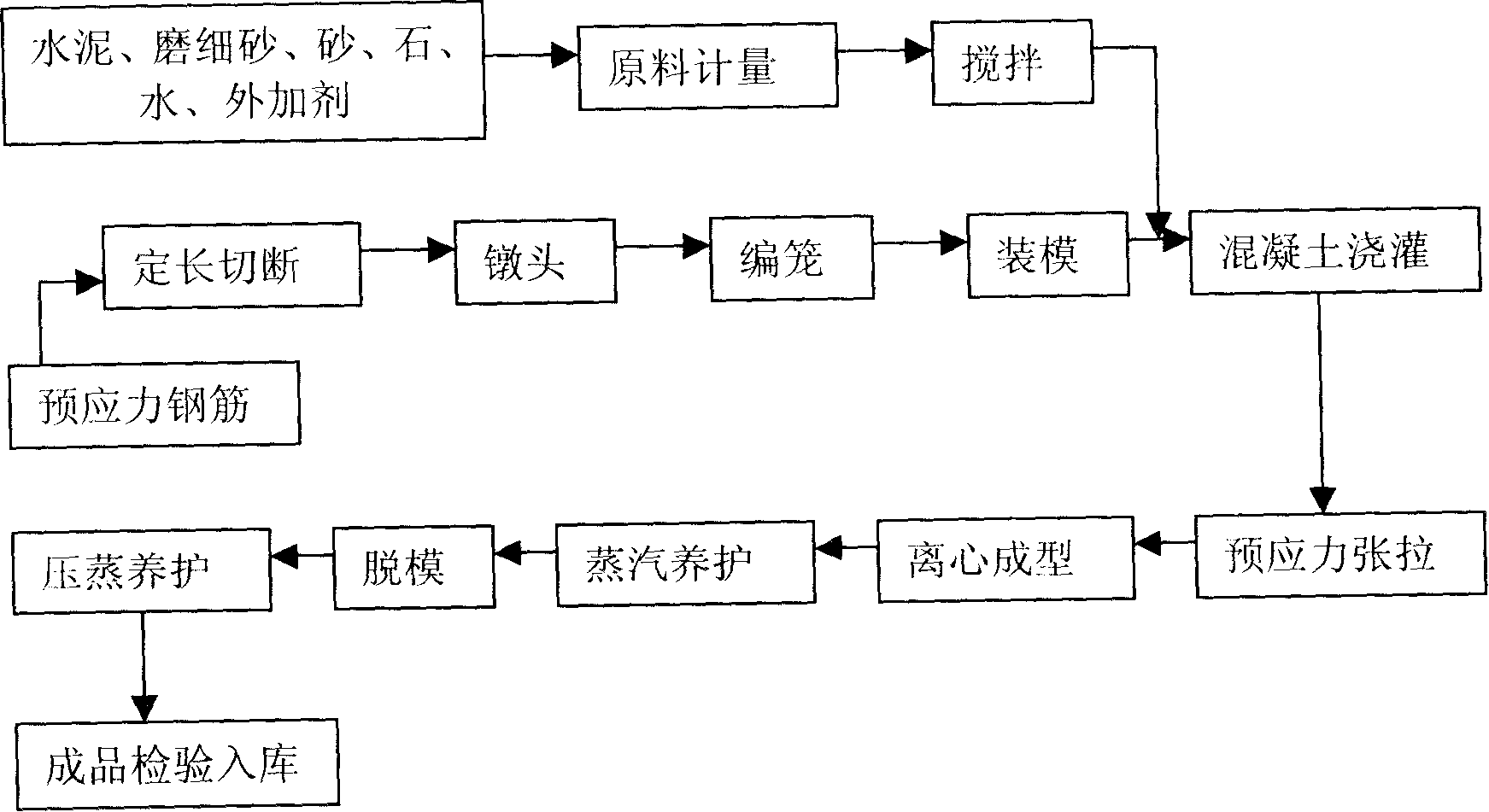

Method for producing concrete by reclaiming and reusing PHC pipe pile residual slurry

A PHC pipe pile and concrete technology, which is applied in chemical instruments and methods, clay preparation equipment, mixing operation control, etc., can solve the problems of fluctuations in the appearance and quality of concrete strength pipe piles, poor formation of the inner wall of pipe piles, and increased proportion of residual slurry, etc. Problems, to achieve the effect of increased strength, easy control, and resource saving in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

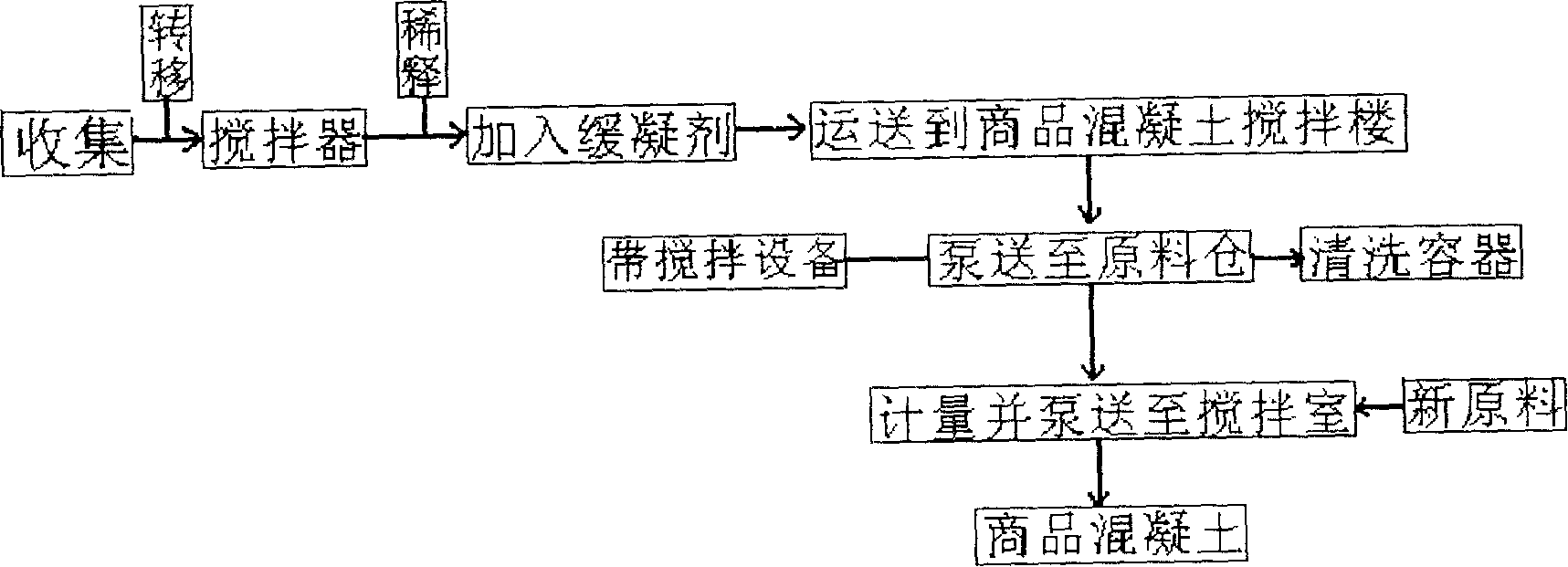

[0018] Such as figure 2 Shown, the method that the present invention recycles and utilizes PHC pipe pile surplus slurry to produce concrete comprises the steps:

[0019] (1) Collect the residual slurry produced after the centrifugation of the PHC pipe pile into a fixed container, and transfer to another container with a stirring device and a scale;

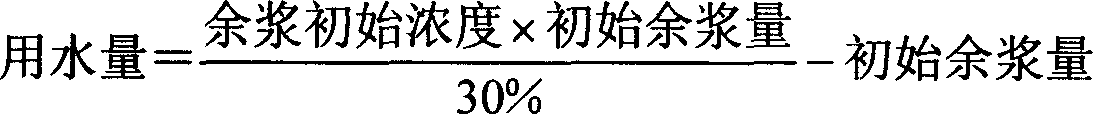

[0020] (2) measure the residual slurry specific gravity, and calculate the residual slurry solid content according to the following mathematical formula,

[0021] Y=AX-B

[0022] Among them, A and B are the measured parameter values of the physical properties of the residual pulp, and the error is controlled within a certain range, Y is the solid content (%) of the residual pulp, and X is the specific gravity of the residual pulp (kg / m 3 ), the mathematical formula between the solid content of the residual slurry and the specific gravity has no obvious change under normal temperature and pressure. This mathematical formula is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com