A kind of anti-cracking thermal insulation wall building material and preparation method thereof

A technology for building materials and thermal insulation walls, applied in the field of building materials, can solve the problems of easy cracking and durability of plastering mortar, and achieve the effects of improving interface compatibility, improving thermal insulation, and reducing the compression-to-fold ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

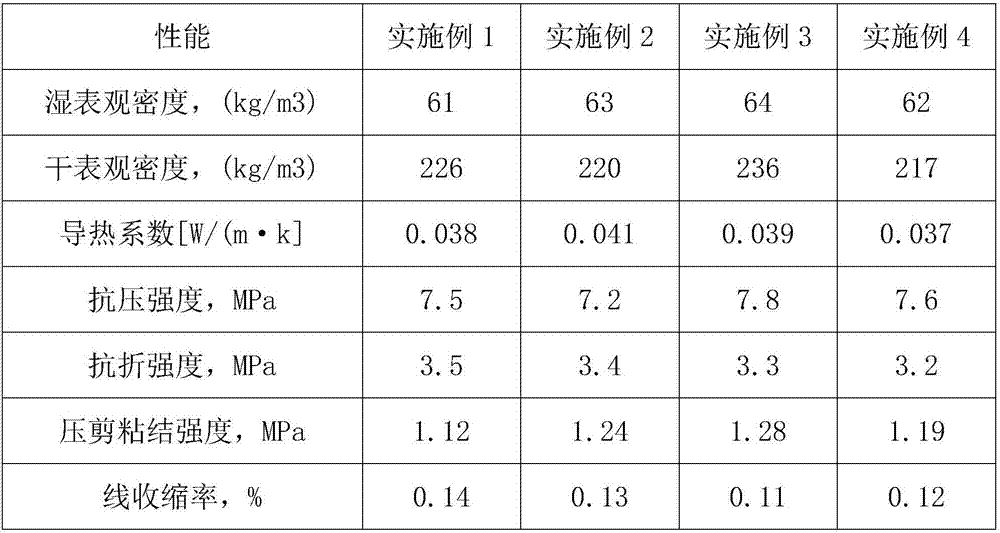

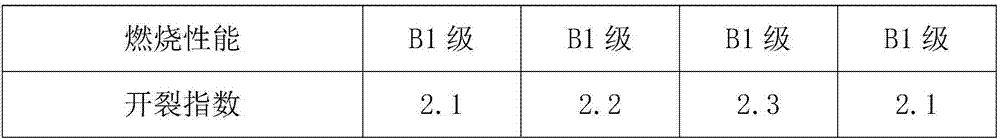

Examples

Embodiment 1

[0020] A kind of anti-crack thermal insulation wall construction material, its raw material comprises by weight: 400 parts of cement, 70 parts of silicon micropowder, 80 parts of ash calcium powder, 160 parts of expanded vermiculite, 60 parts of quartz sand, 100 parts of hollow glass microspheres, 40 parts of rock wool silk, 80 parts of modified fly ash, 60 parts of polystyrene particles, 20 parts of wood fiber, 5 parts of polypropylene fiber, 60 parts of polyvinyl alcohol powder, 40 parts of ethylene-vinyl acetate copolymer, hydroxyethyl 20 parts of methyl cellulose;

[0021] Wherein, the method for preparing the modified fly ash includes: adding the fly ash with a particle size ≥ 20 mesh into a mixed acid solution of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 1:3, and ultrasonically treating it at 50°C for 0.5h , the ultrasonic frequency is 40KHz, and the sound intensity is 0.1W / cm 2 , cooled to room temperature, suction filtered, washed,...

Embodiment 2

[0024] A kind of anti-crack thermal insulation wall construction material, its raw material comprises by weight: 600 parts of cement, 40 parts of silicon micropowder, 220 parts of ash calcium powder, 80 parts of expanded vermiculite, 100 parts of dolomite sand, 60 parts of hollow glass microspheres , 80 parts of rock wool silk, 30 parts of modified fly ash, 120 parts of polystyrene particles, 10 parts of wood fiber, 10 parts of polypropylene fiber, 30 parts of polyvinyl alcohol powder, 80 parts of vinyl acetate-ethylene tertiary carbonate copolymer, 10 parts of carboxymethyl cellulose;

[0025] Wherein, the method for preparing the modified fly ash includes: adding the fly ash with a particle size ≥ 20 mesh into a mixed acid solution of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 1:5, and ultrasonically treating it at 30° C. for 3 hours, Ultrasonic frequency is 20KHz, sound intensity is 0.3W / cm 2 , cooled to room temperature, suction filtere...

Embodiment 3

[0028] A kind of anti-crack thermal insulation wall construction material, its raw material comprises by weight: 500 parts of cement, 55 parts of silicon micropowder, 150 parts of ash calcium powder, 120 parts of expanded vermiculite, 80 parts of sea sand, 80 parts of hollow glass microspheres, 60 parts of rock wool silk, 55 parts of modified fly ash, 90 parts of polystyrene particles, 15 parts of wood fiber, 7 parts of polypropylene fiber, 45 parts of polyvinyl alcohol powder, 60 parts of ethylene-vinyl laurate-vinyl chloride copolymer Parts, 15 parts of hydroxyethyl cellulose;

[0029] Wherein, the method for preparing the modified fly ash includes: adding the fly ash with a particle size ≥ 20 mesh into a mixed acid solution of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 1:4, and ultrasonically treating it at 40°C for 1.5h , the ultrasonic frequency is 30KHz, and the sound intensity is 0.2W / cm 2 , cooled to room temperature, suction filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com