Fiber reinforced regenerated fine aggregate cement-based composite material

A technology of recycled fine aggregate and composite materials, which is applied in the field of fiber-reinforced recycled fine aggregate cement-based composite materials and its preparation, and can solve the problems of crack resistance, shrinkage resistance, frost resistance, and replacement rate. It should not exceed 50%, increase in strength and other problems, so as to achieve the effects of easy promotion and application, local materials and processing costs, and improved frost resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

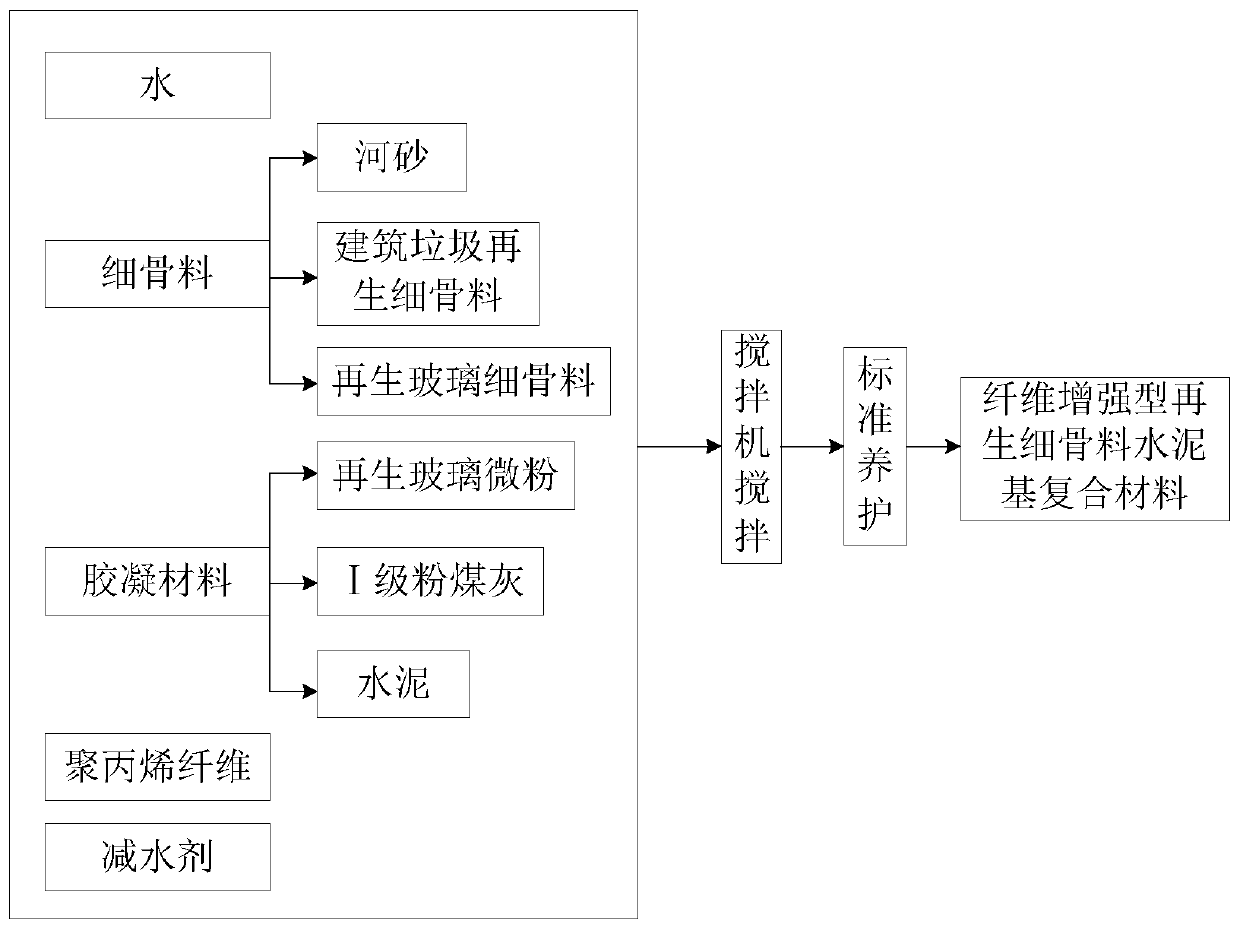

Method used

Image

Examples

Embodiment 1 to 10

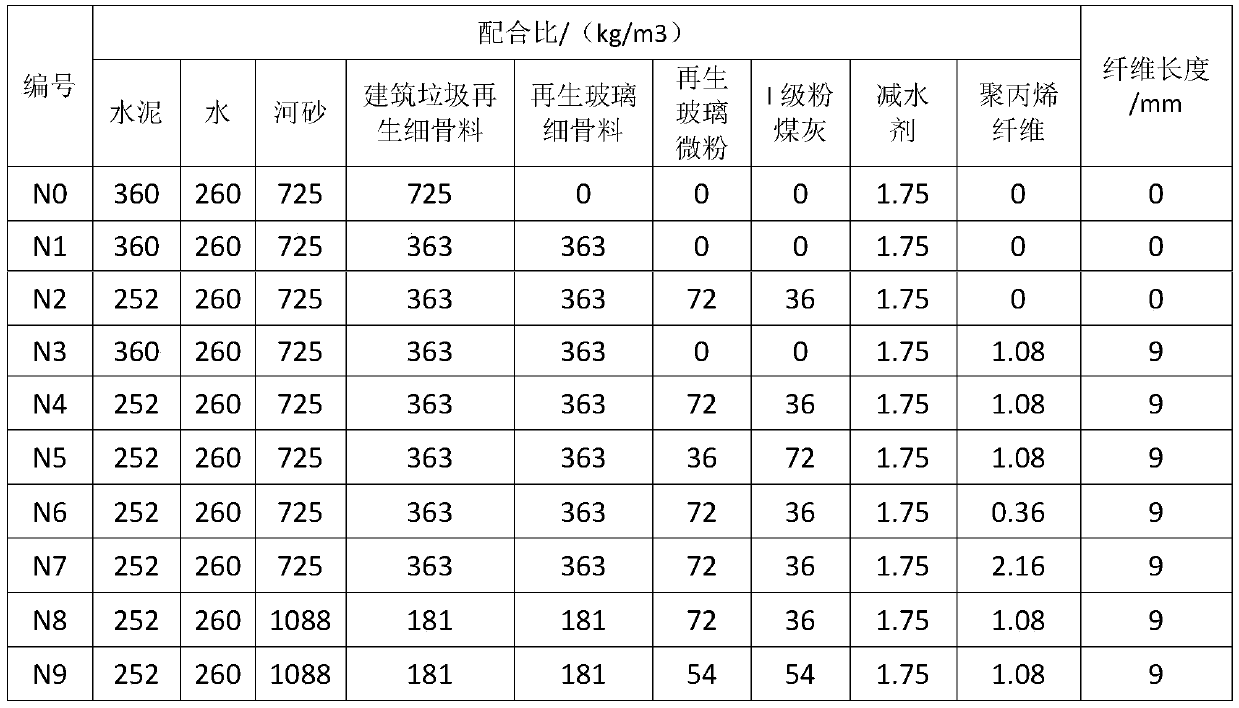

[0034] The ratio of each component of the fiber-reinforced recycled fine aggregate cement-based composite material is as follows:

[0035] The cement is P.O32.5 ordinary Portland cement with a strength grade of 32.5.

[0036] water.

[0037] River sand is high-quality river sand produced in Songhua River, Jilin City, with a particle size of 0.15-5.00mm.

[0038] Recycled fine aggregate is composed of recycled fine aggregate from construction waste and recycled glass fine aggregate. According to the calculation of fine aggregate particle gradation curve of 0.15-5.00mm: gradation part of 1.18-5.00mm and gradation part of 0.15-1.18mm The mass ratio is 1:1, in which the recycled fine aggregate of construction waste constitutes the gradation part of the recycled fine aggregate of 1.18-5.00mm, and the recycled glass fine aggregate constitutes the graded part of the recycled fine aggregate of 0.15-1.18mm.

[0039] The recycled fine aggregate of construction waste is recycled brick ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com