Dry-mixed mortar for pavement and preparation process thereof

A technology of dry powder mortar and mineral powder, which is applied in the field of building materials, can solve the problems of dry powder mortar construction performance and mechanical performance adverse effects, reduced service life of the road surface, and impact on the wear resistance of the road surface, so as to achieve excellent mechanical properties, increase water retention performance, Improve the effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

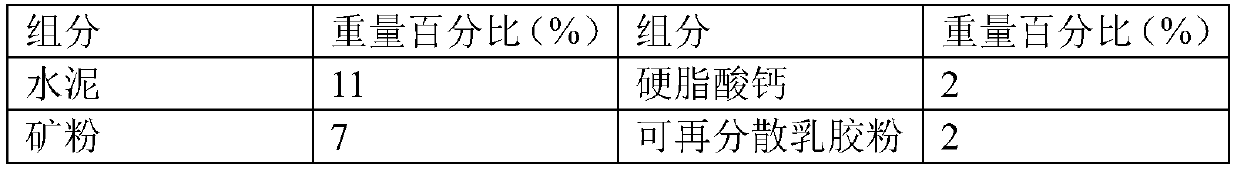

[0035] Table 1 A kind of dry powder mortar used for pavement and its weight percentage

[0036]

[0037]

[0038] Wherein the preparation method of the modified bentonite is: 1) 20kg of glucose is added into 300L water, and stirred until the glucose is completely dissolved; 2) Then continue to add 100kg of bentonite, stirring constantly, so that the bentonite is evenly dispersed; 3) Adjust the pH to 12-13, and then Raise the temperature to 80°C, stir for 6 hours, centrifuge after stirring, wash the precipitate with water for 5 times and then dry, the drying temperature is lower than 140°C, after drying, grind into powder to obtain modified bentonite.

[0039] The preparation technology of this dry powder mortar specifically comprises the following steps:

[0040] Step 1, first drying the yellow sand with a dryer, the moisture content after drying is less than 0.5%, screening the dried yellow sand, and then placing the screened yellow sand in a storage tank for subsequent...

Embodiment 2

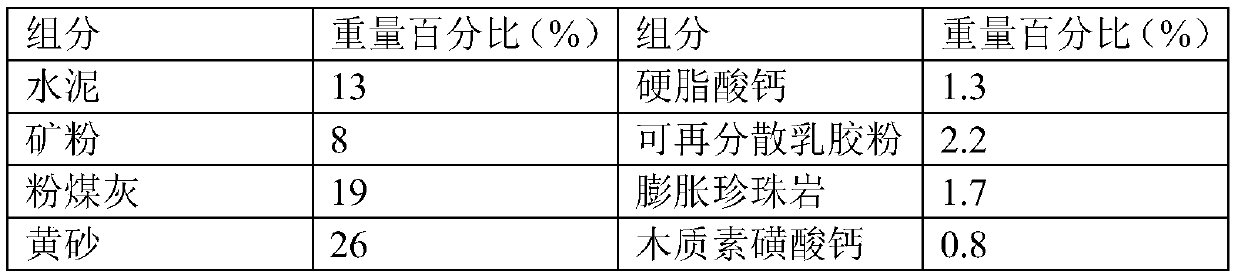

[0043] Table 2 A kind of dry powder mortar used for pavement and its weight percentage

[0044] components weight percentage (%) components weight percentage (%) cement 12 Calcium stearate 1 mineral powder 6 Redispersible latex powder 2 fly ash 17 expanded perlite 2 yellow sand 33 calcium lignosulfonate 0.6 Modified bentonite 11 Aquasorb 0.8 stone powder 10 Dry powder defoamer 0.9 thickened powder 3 air entraining agent 0.7

[0045] Wherein the preparation method of modified bentonite is as follows: 1) 25kg of glucose is added into 400L of water, and stirred until the glucose is completely dissolved; 2) then continue to add 110kg of bentonite, stirring constantly, so that the bentonite is evenly dispersed; 3) adjust the pH to 12-13, and then Raise the temperature to 100°C, stir for 5 hours, centrifuge after stirring, wash the precipitate with water for 4 times and then dry, the drying temperature i...

Embodiment 3

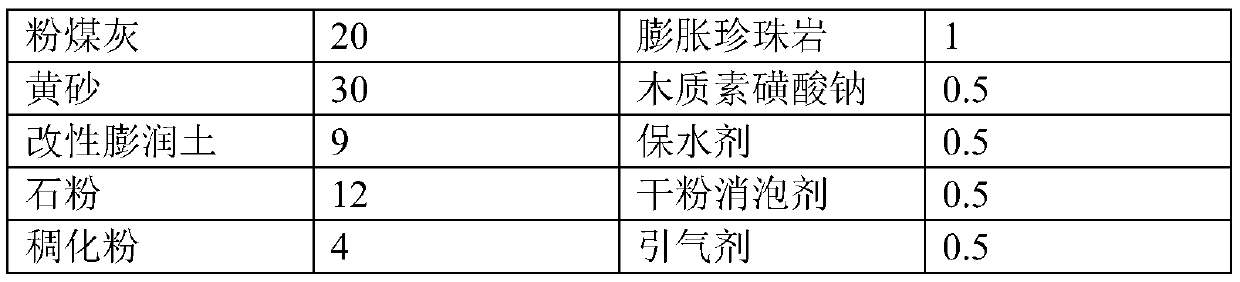

[0048] Table 3 A kind of dry powder mortar used for pavement and its weight percentage

[0049]

[0050]

[0051] Wherein the preparation method of the modified bentonite is: 1) 30kg of glucose is added into 350L of water, and stirred until the glucose is completely dissolved; 2) Then continue to add 120kg of bentonite, stirring constantly, so that the bentonite is evenly dispersed; 3) Adjust the pH to 12-13, and then Raise the temperature to 120°C, stir for 4 hours, centrifuge after stirring, wash the precipitate with water for 3 times and then dry, the drying temperature is lower than 140°C, after drying, grind into powder to obtain modified bentonite.

[0052] The preparation technology of this dry powder mortar is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com