Preparation method of hydrophobic mortar

A technology of water-repellent sand and water-repellent agent, applied in the field of liquid waterproofing agent, can solve the problems of unstable construction quality, influence on waterproofing quality, many human factors, etc., achieve obvious social and economic benefits, improve living environment, and ease Good performance and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

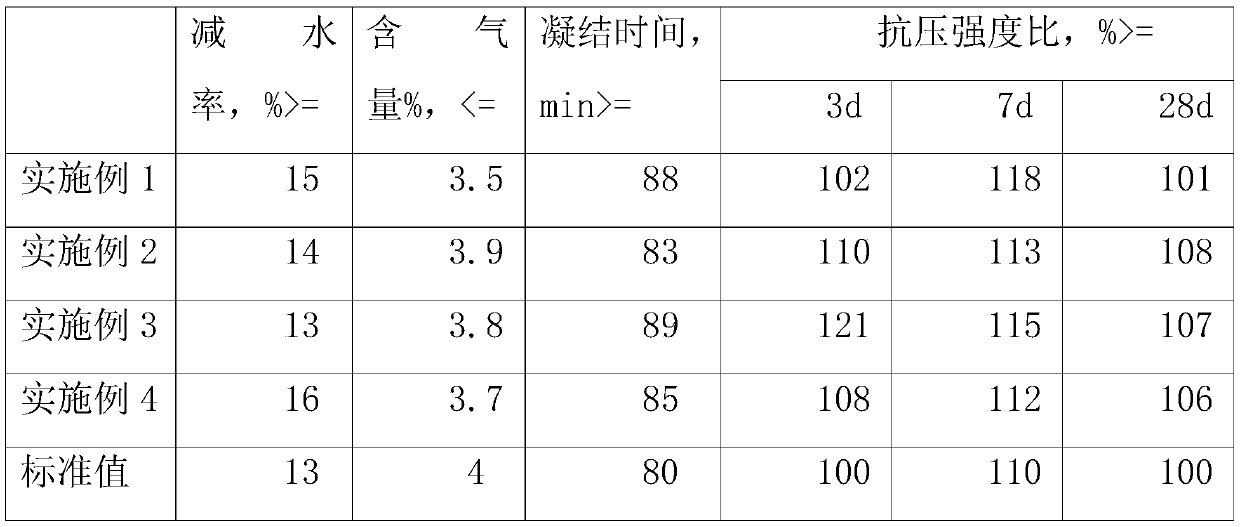

Examples

Embodiment 1

[0023] Take the following raw materials in parts by weight: cement 20; aggregate 50; coal ash powder 15; slag 0.2; naphthalene-based water reducer 0.25; Latex powder 0.23.

[0024] 1. Quantitatively inject hot water into the stirred tank, and the water temperature is 75°C.

[0025] 2. Quantitatively put coal ash powder and slag into the above water, and stir to make the solution evenly mixed.

[0026] 3. Quantitatively add aggregate to the solution obtained in step (2) while stirring, and stir for 2 hours.

[0027] 4. At a temperature of 22°C, add naphthalene-based water reducer, stir, and place for 1.5 hours.

[0028] 5. At a temperature of 10°C, add aliphatic water reducer, water repellent, cellulose ether, redispersible latex powder, and cement quantitatively while stirring, and stir for 0.8 hours.

[0029] 6. Use 20% potassium hydroxide or sodium hydroxide solution to adjust the pH value of the waterproof solution within the range of 11.

Embodiment 2

[0031] Take the following raw materials in parts by weight: cement 30; aggregate 70; coal ash powder 30; slag 1; naphthalene-based water reducer 0.5; Latex powder 0.46.

[0032] 1. Quantitatively inject hot water into the stirred tank, and the water temperature is 80°C.

[0033] 2. Quantitatively put coal ash powder and slag into the above water, and stir to make the solution evenly mixed.

[0034] 3. Quantitatively add aggregate to the solution obtained in step (2) while stirring, and stir for 2.5 hours.

[0035] 4. At a temperature of 30°C, add naphthalene-based water reducer, stir, and place for 1.5 hours.

[0036] 5. At a temperature of 30°C, add aliphatic water reducer, water repellent, cellulose ether, redispersible latex powder, and cement quantitatively while stirring, and stir for 0.8 hours.

[0037] 6. Use 20% potassium hydroxide or sodium hydroxide solution to adjust the pH value of the waterproof solution within 10.

Embodiment 3

[0039] Take the following raw materials in parts by weight: cement 30; aggregate 50; coal ash powder 30; slag 0.2; naphthalene-based water reducer 0.25; Latex powder 0.23.

[0040] 1. Quantitatively inject hot water into the stirred tank, and the water temperature is 100°C.

[0041] 2. Quantitatively put coal ash powder and slag into the above water, and stir to make the solution evenly mixed.

[0042] 3. Quantitatively add aggregate to the solution obtained in step (2) while stirring, and stir for 5 hours.

[0043] 4. At a temperature of 50°C, add naphthalene-based water reducer, stir, and place for 3 hours.

[0044] 5. At a temperature of 50°C, add aliphatic water reducer, water repellent, cellulose ether, redispersible latex powder, and cement quantitatively while stirring, and stir for 5 hours.

[0045] 6. Use 20% potassium hydroxide or sodium hydroxide solution to adjust the pH value of the waterproof solution within the range of 9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com