Method for improving hydrophilicity and thermal stability of polypropylene lithium-ion battery separator

A lithium-ion battery, thermal stability technology, applied in the direction of battery components, circuits, electrical components, etc., can solve the problems of easy peeling off of the coated modified coating, difficult operation of graft modification, etc., and achieve the modification method Simple, simple experimental operation, prevent shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The monomer diallyl dimethyl ammonium chloride (4.5g) was added in distilled water (30mL), and the initiator ammonium persulfate (APS, the amount of the initiator accounted for 1% of the monomer mass) was added to the distilled water, And react at 70°C for 10 hours to obtain a cationic polyelectrolyte (homopolymer of diallyldimethylammonium chloride) solution;

[0042] Add monomer acrylic acid (4.5g) to distilled water (30mL), add initiator ammonium persulfate (APS, the amount of initiator accounts for 1% of monomer mass) to distilled water, and react at 70°C for 10h, During the reaction, by adding 1mol / L sodium hydroxide solution to the system, the final pH value of the reaction system was adjusted to be 7 to obtain an anionic polyelectrolyte (acrylic acid-sodium acrylate copolymer) solution;

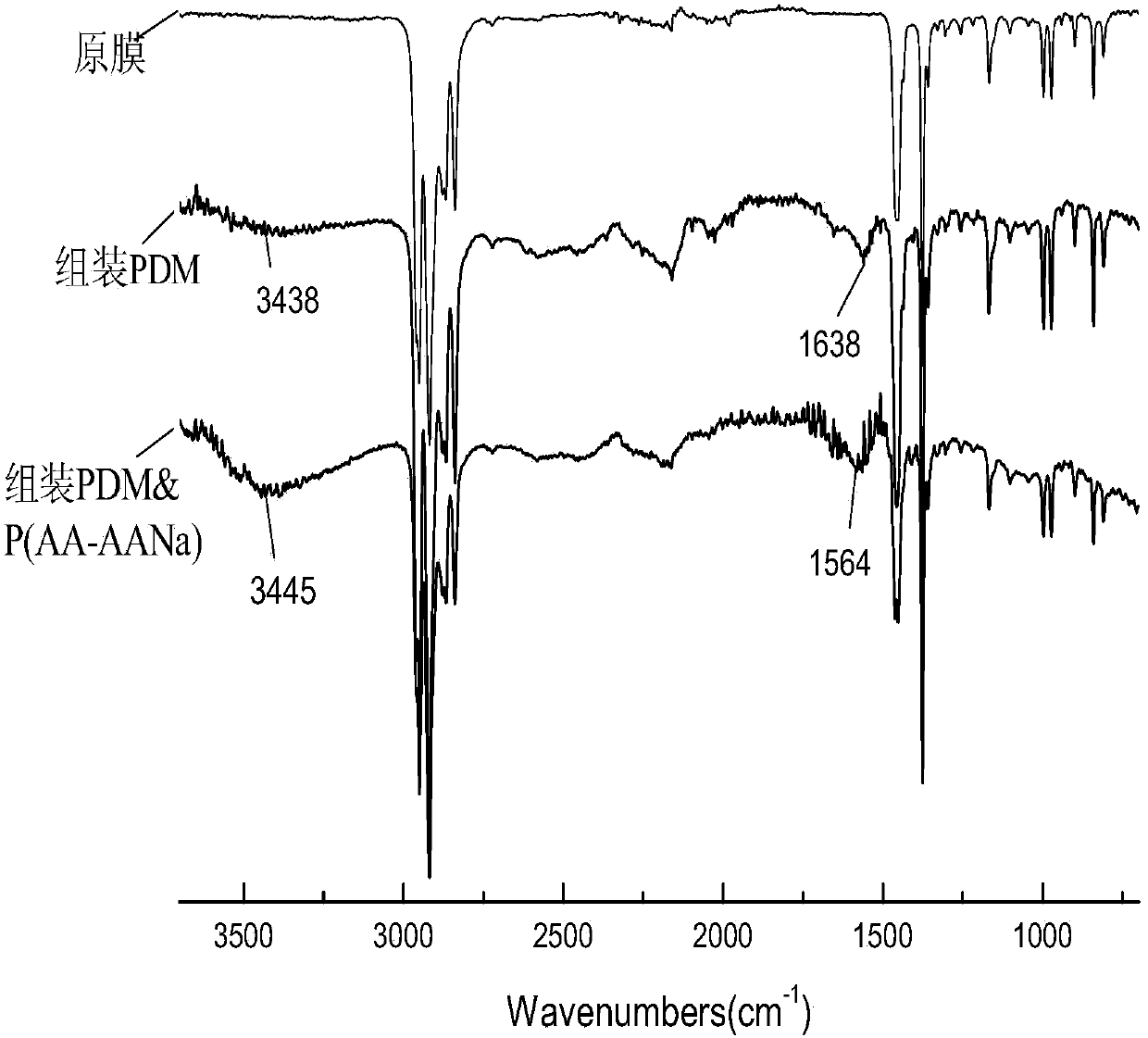

[0043] Pretreatment: the original polypropylene microporous membrane (infrared spectrum as attached figure 1 The spectral line corresponding to the "original film" in the middl...

Embodiment 2

[0047] Get 4.5g of the total mass of diallyldimethylammonium chloride and acrylamide, dissolve it in 30mL of water, add 0.045g (accounting for 1% of the total monomer mass) initiator ammonium persulfate to the system at 70°C After reacting for 10 hours, a cationic polyelectrolyte (copolymer of diallyldimethylammonium chloride and acrylamide) solution was prepared. Wherein, the ratio of the amount of diallyldimethylammonium chloride monomer to the amount of acrylamide monomer is 7:1, and the consumption is 4.2g and 0.3g respectively;

[0048] Take 4.5 g of the total mass of acrylic acid and acrylamide, add it to 30 mL of distilled water, add 0.045 g of initiator ammonium persulfate (accounting for 1% of the total mass of the monomer) and react at 70 ° C for 10 h to prepare an anionic polyelectrolyte (acrylic acid- Acrylamide copolymer) solution, wherein, the ratio of the amount of acrylic acid monomer and acrylamide monomer is 9:1, and the consumption is respectively 4.0g and 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| Gurley value | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com