Method for preparing water-resistant thermal insulation mortar from modified rubber particles

A technology of modified rubber and thermal insulation mortar is applied in the field of preparing water-resistant thermal insulation mortar with modified rubber particles, which can solve the problems of large heat release of high-power electromechanical equipment, endangering the health of miners, loss of thermal insulation performance, etc., and achieves a reduction in water absorption rate , Improve cracking and tensile strength, improve the effect of modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

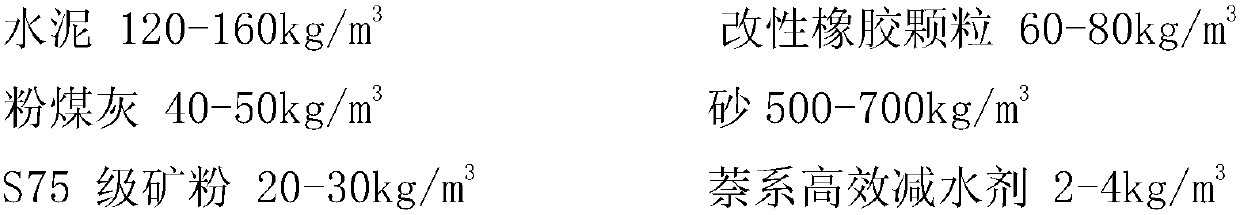

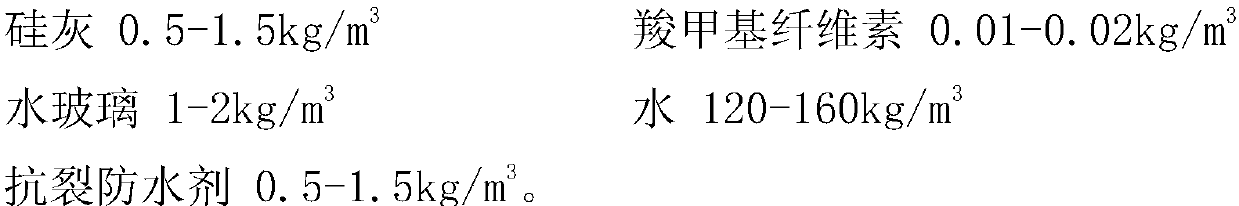

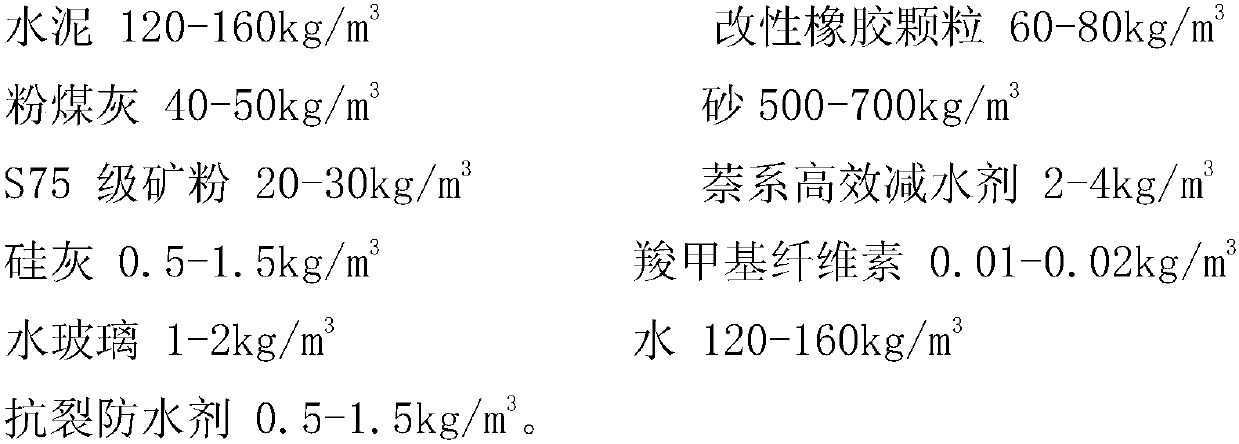

Embodiment 1

[0037] A method for preparing water-resistant thermal insulation mortar by modified rubber particles, the method comprising:

[0038] (1) Preparation of modified rubber particles

[0039] Soak the rubber particles in lye for 2 hours. The lye is 1% NaOH aqueous solution. After kneading, washing and filtering, remove the hydrophobic surface layer to present a rough surface, then rinse it with water for 4 times, and dry it at 75°C In a water bath environment, the treated rubber particles and coupling modifier are added to the water bath container for stirring, and the modified rubber particles are obtained after drying;

[0040] The coupling modifier is prepared from the following substances, and its substance content is calculated as a mass percentage of the rubber particles:

[0041] Coupling agent: 6%;

[0042] Initiator: 0.4%;

[0043] Water reducer: 6%;

[0044] Water: 60%;

[0045] The coupling agent is a vinyltriethoxysilane coupling agent;

[0046] The initiator is ...

Embodiment 2

[0057] A method for preparing water-resistant thermal insulation mortar by modified rubber particles, the method comprising:

[0058] (1) Preparation of modified rubber particles

[0059] Soak the rubber particles in lye for 3 hours. The lye is 2% NaOH aqueous solution. After kneading and filtering, remove the hydrophobic surface layer to present a rough surface, then rinse it with water for 5 times, and dry it at 80°C In a water bath environment, the treated rubber particles and coupling modifier are added to the water bath container for stirring, and the modified rubber particles are obtained after drying;

[0060] The coupling modifier is prepared from the following substances, and its substance content is calculated as a mass percentage of the rubber particles:

[0061] Coupling agent: 7%;

[0062] Initiator: 0.5%;

[0063] Water reducer: 7%;

[0064] Water: 65%;

[0065] The coupling agent is a vinyltriethoxysilane coupling agent;

[0066] The initiator is a peroxide ...

Embodiment 3

[0077] A method for preparing water-resistant thermal insulation mortar by modified rubber particles, the method comprising:

[0078] (1) Preparation of modified rubber particles

[0079] Soak the rubber particles in lye for 4 hours. The lye is 3% NaOH aqueous solution. After kneading and filtering, remove the hydrophobic surface layer to present a rough surface, then rinse it with water for 6 times, and dry it at 85°C In a water bath environment, the treated rubber particles and coupling modifier are added to the water bath container for stirring, and the modified rubber particles are obtained after drying;

[0080] The coupling modifier is prepared from the following substances, and its substance content is calculated as a mass percentage of the rubber particles:

[0081] Coupling agent: 8%;

[0082] Initiator: 0.6%;

[0083] Water reducer: 8%;

[0084] Water: 70%;

[0085] The coupling agent is a vinyltriethoxysilane coupling agent;

[0086] The initiator is a peroxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com