Cement-based steel slag sand mending material used for mending buildings

A steel slag sand, cement-based technology is applied in the repair of cement concrete buildings and structures, and the field of steel slag sand repair mortar. , good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

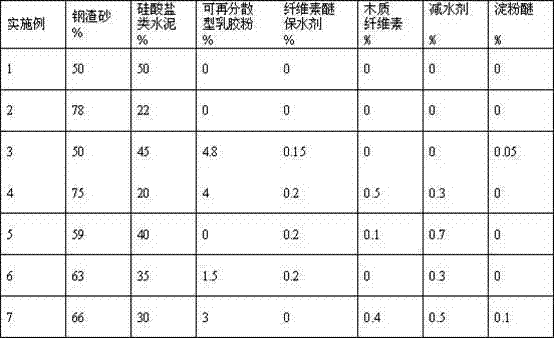

[0017] The present invention is described in detail below: Table 1 and Table 2 are the value list of each embodiment of the present invention and comparative example; Table 3 is the test result list of each embodiment of the present invention and comparative example.

[0018] Table 1 Value list (wt%) of each embodiment of the present invention

[0019]

[0020] Note: the cement used in example 3 is 32.5 grade composite Portland cement, the cement used in example 4 is 42.5 grade Portland cement, and the cement used in other examples is P.O 42.5 grade ordinary Portland cement; the steel slag used in example 3 The particle size range of sand is 0-0.6mm, the particle size range of steel slag sand used in Example 6 is 0-0.18mm, the particle size range of steel slag sand used in Example 4 is 0-2.36mm, and the particle size range of steel slag sand used in other examples is 0-4.75mm.

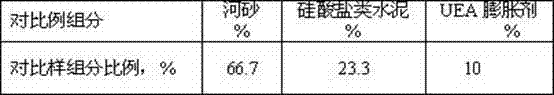

[0021] Table 2 Component proportions of river sand comparison samples (wt%)

[0022]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com