Modified rubber particles for mortar and preparation method of modified rubber particles

A technology of rubber granules and modified rubber, which is applied in the direction of climate sustainability, sustainable waste treatment, and solid waste management. Improve the affinity, facilitate the recycling of solid waste, and improve the effect of modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

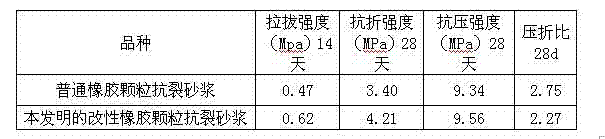

[0031] Example 1, soak 40-mesh rubber particles in NaOH solution with a concentration of 5% for 4 to 6 hours, remove the hydrophobic surface layer and present a rough surface, wash and filter with water for 2 to 3 times, and then Filter and dry, and after drying, add the treated rubber particles, initiator, coupling agent, water, and water reducer in a weight ratio of 100; 0.3:2:30:3 in a water bath environment at 60°C In a water bath device, stir at 300 rpm for 30 minutes, and finally dry to obtain powdery modified rubber particles. Compared with ordinary mortar, the mortar prepared with rubber particles modified by this formula can reduce the folding ratio of mortar by 20% under the same fluidity, and the bonding strength between mortar and cement base can be increased by 15%. At the same time, the crack resistance of mortar Improved.

Embodiment 2

[0032] Example 2, soak 40-mesh rubber particles in NaOH solution with a concentration of 5% for 4 to 6 hours, remove the hydrophobic surface layer and present a rough surface, wash and filter, rinse with water for 2 to 3 times, and then Filter and dry, and after drying, add the treated rubber particles, initiator, coupling agent, water, and water reducing agent in a weight ratio of 100:0.1:2:50:5 in a water bath environment at 60°C In a water bath device, stir at 300 rpm for 30 minutes, and finally dry to obtain powdery modified rubber particles. Compared with ordinary mortar, the mortar prepared with rubber particles modified by this formula can reduce the folding ratio of mortar by 22% under the same fluidity, and the bonding strength between mortar and cement base can be increased by 16%. At the same time, the mortar has crack resistance Improved.

Embodiment 3

[0033] Example 3, soak 40-mesh rubber particles in NaOH solution with a concentration of 5% for 4-6 hours, remove the hydrophobic surface layer and present a rough surface, wash and filter, rinse with water 2-3 times, and then Filter and dry, and after drying, add the treated rubber particles, initiator, coupling agent, water, and water reducer in a weight ratio of 100:0.3:5:50:5 in a water bath environment at 60°C In a water bath device, stir at 300 rpm for 30 minutes, and finally dry to obtain powdery modified rubber particles. Compared with ordinary mortar, the mortar made of rubber particles modified by this formula can reduce the indentation ratio of mortar by 20% under the same fluidity, and the bonding strength between mortar and cement base can be increased by 18%. At the same time, the crack resistance of mortar Improved.

[0034] The coupling agent described in the above-mentioned Examples 1-3 is a vinyltriethoxysilane coupling agent. The initiator is a peroxide in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com