Rubber aggregate dry-mixed mortar

A technology of rubber aggregate and dry powder mortar, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability. It can solve the problems of thick plaster without cracks, no heat preservation effect, and insufficient flexibility. Achieve the effects of easy operation, improved flexibility and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The mass ratio of each component is as follows:

[0024] Cement: 1, sand: 1.75, water: 0.6, rubber aggregate: 0.27, methyl cellulose ether: 0, wood fiber: 0.018, redispersible rubber powder: 0.055.

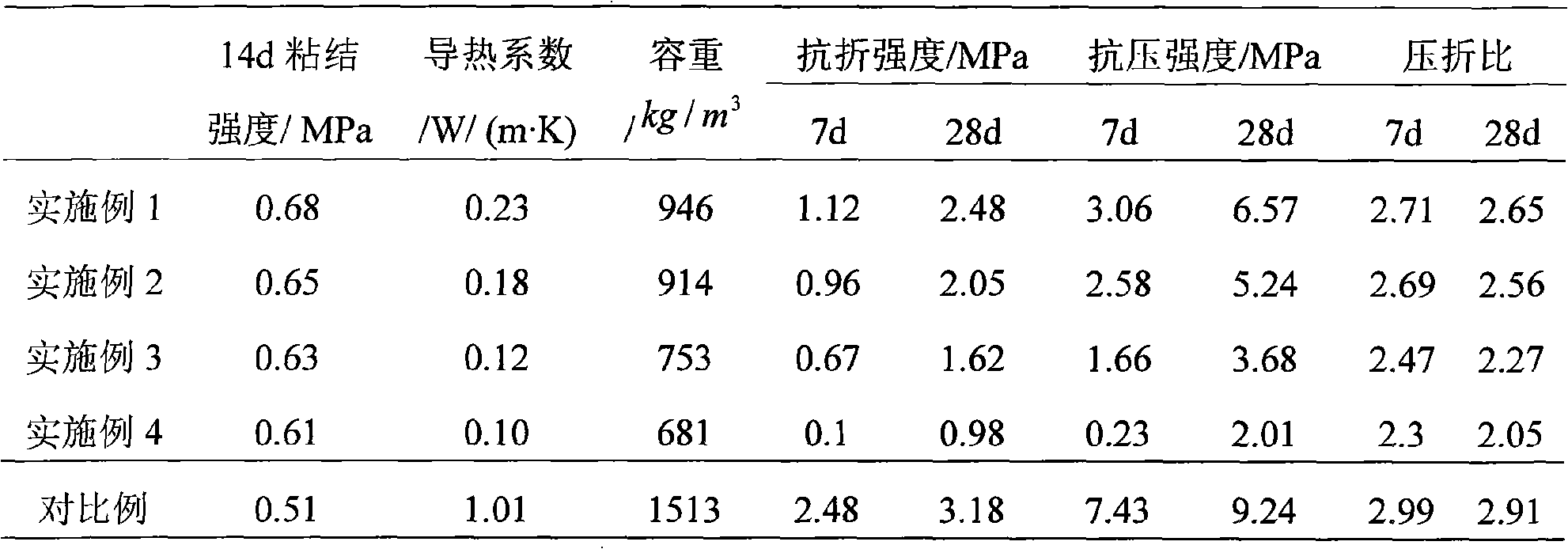

[0025] Accurately weigh rubber aggregate, sand, redispersible rubber powder, wood fiber and methyl cellulose ether according to the above mixing ratio; after mixing them evenly, add water with a specified mass ratio and stir, and it can be used after stirring evenly. The properties of the prepared rubber aggregate dry powder mortar were tested, and the test results are shown in Table 1.

Embodiment 2

[0027] The mass ratio of each component is as follows:

[0028] Cement: 1, sand: 1.25, water: 0.7, rubber aggregate: 0.46, methyl cellulose ether: 0.008, wood fiber: 0.015, redispersible rubber powder: 0.04.

[0029] Accurately weigh rubber aggregate, sand, redispersible rubber powder, wood fiber and methyl cellulose ether according to the above mixing ratio; after mixing them evenly, add water with a specified mass ratio and stir, and it can be used after stirring evenly. The properties of the prepared rubber aggregate dry powder mortar were tested, and the test results are shown in Table 1.

Embodiment 3

[0031] The mass ratio of each component is as follows:

[0032] Cement: 1, sand: 0.75, water: 0.8, rubber aggregate: 0.65, methyl cellulose ether: 0.012, wood fiber: 0, redispersible rubber powder: 0.12.

[0033] Accurately weigh rubber aggregate, sand, redispersible rubber powder, wood fiber and methyl cellulose ether according to the above mixing ratio; after mixing them evenly, add water with a specified mass ratio and stir, and it can be used after stirring evenly. The properties of the prepared rubber aggregate dry powder mortar were tested, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com