Composite phase-change energy storage interior thermal insulation mortar of heliogreenhouse wall and preparation method thereof

A composite phase change and solar greenhouse technology, applied in the field of building functional materials, can solve the problems of low land utilization rate and waste of building materials, and achieve the effects of improving water retention rate, solving poor water resistance and enhancing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

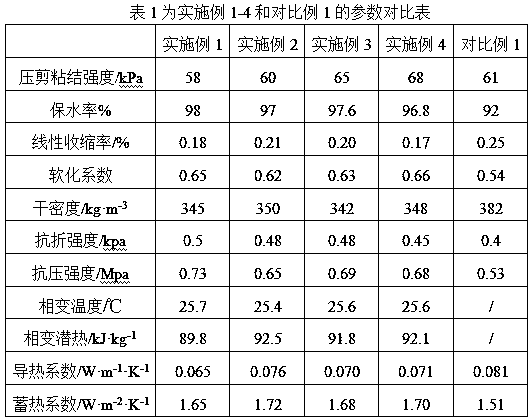

Examples

Embodiment 1

[0035] An energy-saving solar greenhouse wall composite phase change energy storage internal thermal insulation mortar is prepared by mixing raw material dry powder and water accounting for 70% of the total weight of raw material dry powder. The raw material dry powder is obtained by mixing the following components by weight of:

[0036] Desulfurization gypsum 100 parts

[0037] Lightweight composite shape-changing particles 25 parts

[0038] Redispersible latex powder (YJ-606) 3 parts

[0039] 0.15 parts of citric acid

[0040] Hydroxypropyl methylcellulose ether (HPMC-200,000) 1 part

[0041] Polypropylene fiber (PP-6 mm) 0.5 parts.

[0042] The lightweight composite shape-changing particles are obtained by mixing phase-change paraffin and expanded perlite in a weight ratio of 1:1; the phase-change paraffin is 25# phase-change paraffin, and its phase-change temperature is 24.9°C, and the phase-change The latent heat is 186 kJ / kg; the particle size of the expanded perlit...

Embodiment 2

[0050] An energy-saving solar greenhouse wall composite phase change energy storage internal thermal insulation mortar is prepared by mixing raw material dry powder and water accounting for 110% of the total weight of the raw material dry powder. The raw material dry powder is obtained by mixing the following components by weight of:

[0051] Desulfurization gypsum 100 parts

[0052] Lightweight composite shape-changing particles 35 parts

[0053] Redispersible latex powder (YJ-606) 2 parts

[0054] 0.3 parts of citric acid

[0055] Hydroxypropyl methylcellulose ether (HPMC-200,000) 0.5 parts

[0056] Polypropylene fiber (PP-6 mm) 1 part.

[0057] The lightweight composite shape-changing particles are obtained by mixing phase-change paraffin and expanded perlite according to a weight ratio of 2:1; the phase-change paraffin is 25# phase-change paraffin, and its phase-change temperature is 24.9 ° C. The latent heat is 186 kJ / kg; the particle size of the expanded perlite is 1....

Embodiment 3

[0065] An energy-saving solar greenhouse wall composite phase change energy storage internal thermal insulation mortar is prepared by mixing raw material dry powder and water accounting for 90% of the total weight of the raw material dry powder. The raw material dry powder is obtained by mixing the following components by weight of:

[0066] Desulfurization gypsum 100 parts

[0067] Lightweight composite shape-changing particles 28 parts

[0068] Redispersible latex powder (YJ-606) 3 parts

[0069] 0.25 parts of citric acid

[0070] Hydroxypropyl methylcellulose ether (HPMC-200,000) 0.8 parts

[0071] Polypropylene fiber (PP-6 mm) 0.8 parts.

[0072] The lightweight composite shape-changing particles are obtained by mixing phase-change paraffin and expanded perlite in a weight ratio of 3:2; the phase-change paraffin is 25# phase-change paraffin, and its phase-change temperature is 24.9°C, and the phase-change The latent heat is 186 kJ / kg; the particle size of the expanded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com