Thermosetting laser-induced metallization thermal-conduction composite material with stable high dielectric constant

A heat-conducting composite material, laser-induced technology, applied in the field of composite materials, to achieve good high dielectric constant stability, good dimensional stability, low dielectric loss tangent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of material of the present invention is:

[0026] (1) Pour high-dielectric ceramic fillers, laser-induced additives, and high-thermal conductivity fillers into a high-speed mixer, and stir at high speed for 3-5 minutes;

[0027] (2) Slowly add the surfactant to the high-speed mixer, and continue high-speed mixing and stirring for 10-20 minutes;

[0028] (3) Add the thermosetting matrix resin, initiator, thickener, low shrinkage additive and the powder mixed in the above step (2) into a kneader and stir for 15-20 minutes to prepare a composite material.

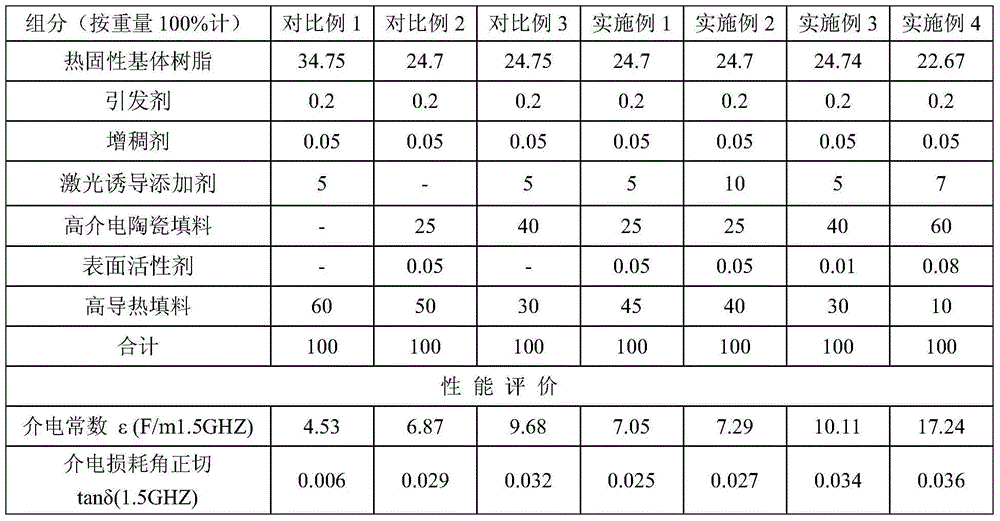

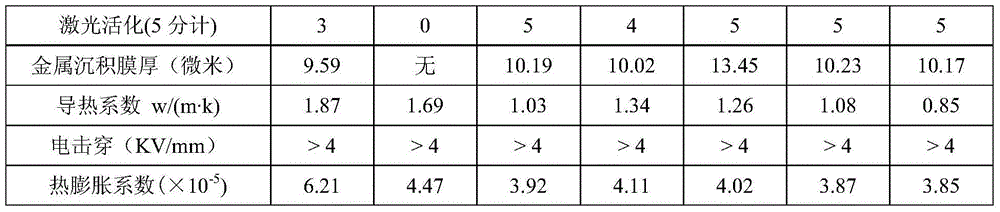

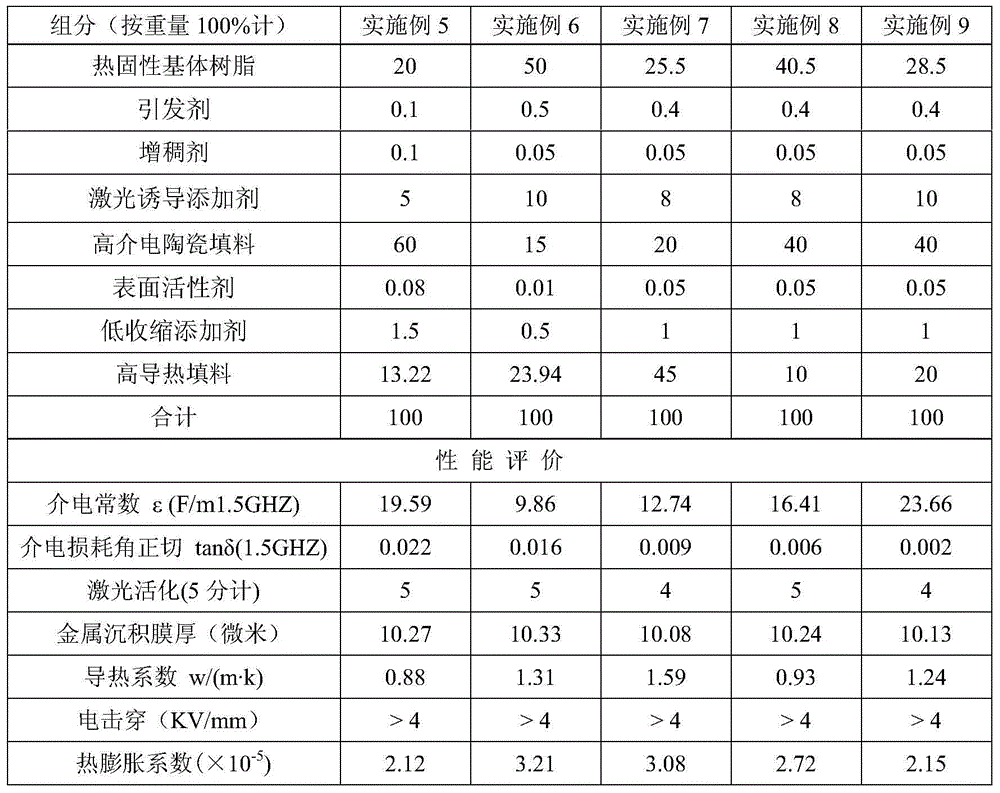

Embodiment 1

[0030] A thermosetting laser-induced metallization heat-conducting composite material with stable high dielectric constant, made by mixing the following components: thermosetting matrix resin (epoxy resin, commercially available), initiator (1,2-cyclohexanediamine) , thickener (magnesium oxide), laser-induced additives, high dielectric ceramic filler (barium titanate, particle size 1-3 microns), surfactant (silane coupling agent KH560), high thermal conductivity filler (spherical alumina, 10 microns, commercially available). The material was then injection molded for corresponding testing.

[0031] The laser-induced additive is a composition of a micron-scale tin-containing compound (tin dioxide) and a nano-scale tin-containing compound (tin dioxide), and the weight ratio of the micron-scale tin-containing compound to the nanoscale tin-containing compound is 4:1; The particle size of the micron-scale tin-containing compound is 0.5-30 μm, and the particle size of the nano-scal...

Embodiment 2

[0034] The composition of this example is the same as that of Example 1, except that the weight ratio of the micron-scale tin-containing compound to the nano-scale tin-containing compound is 9:1.

[0035] The specific proportioning and material performance test of the components in this embodiment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com