Crystal ceramic and preparation method thereof

A crystal porcelain and crystal technology, applied in the field of crystal porcelain, can solve the problems of small firing temperature range, difficult firing control, good thermal stability, etc., and achieve the effects of good thermal stability, increased plasticity, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment.

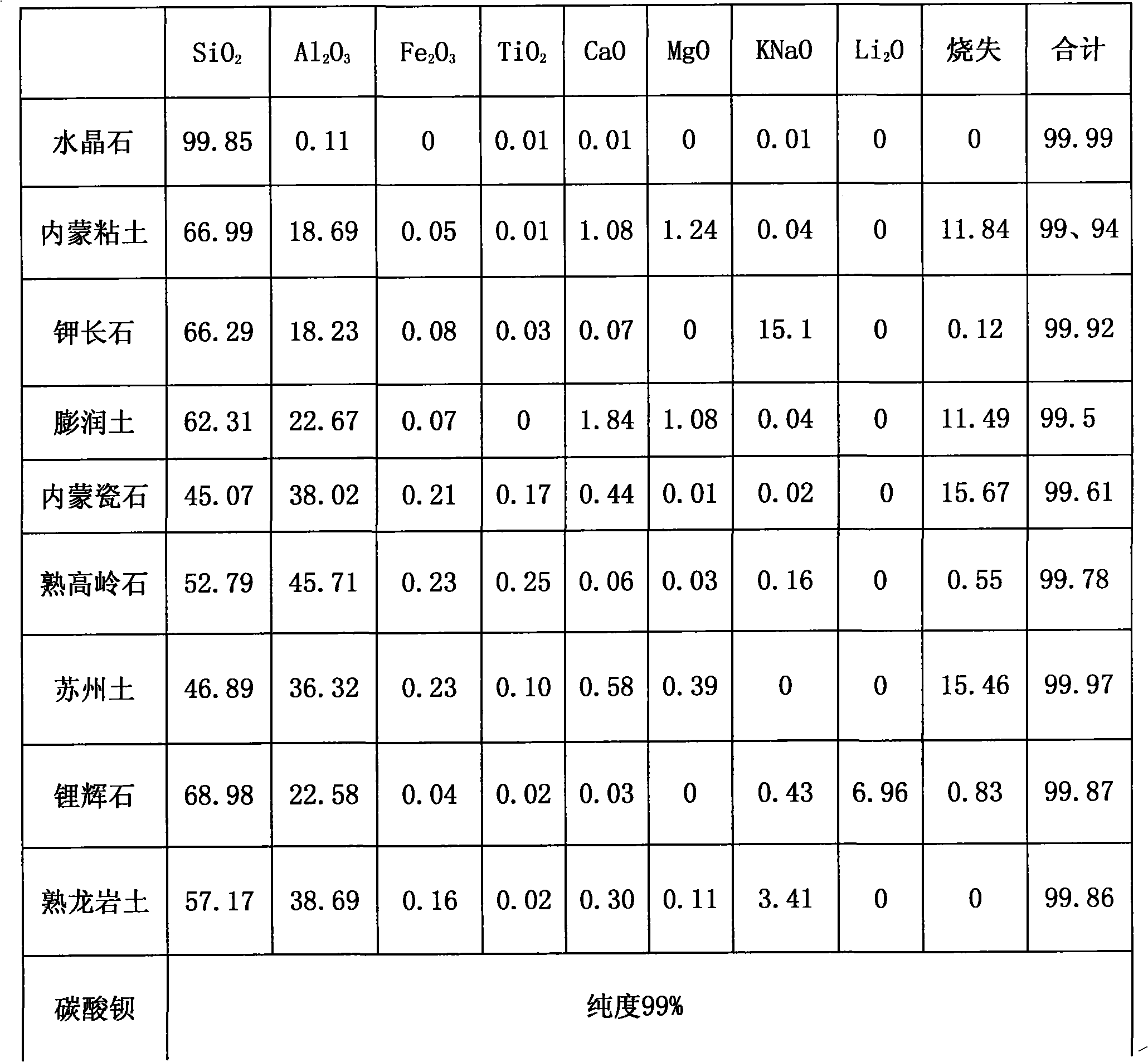

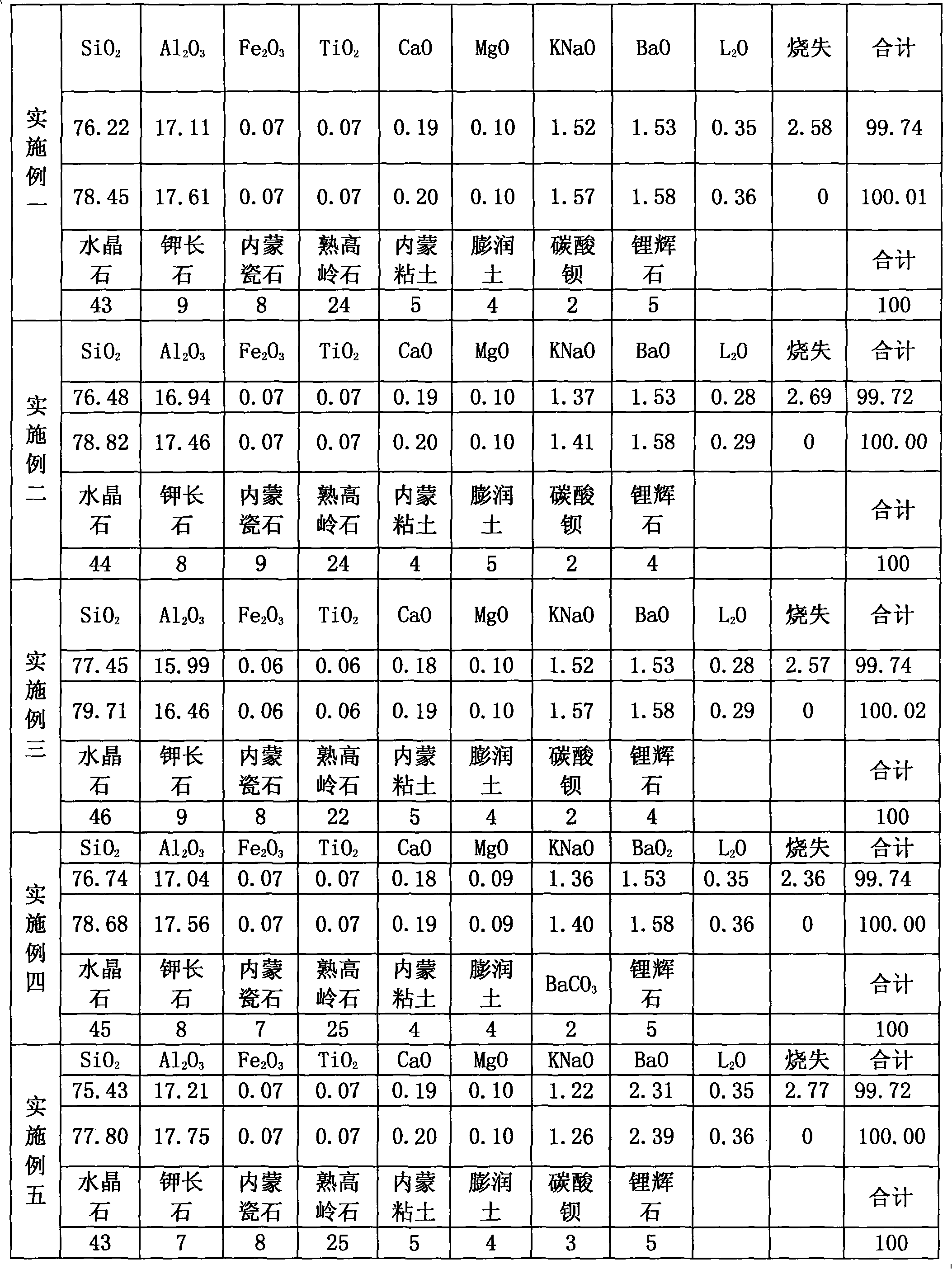

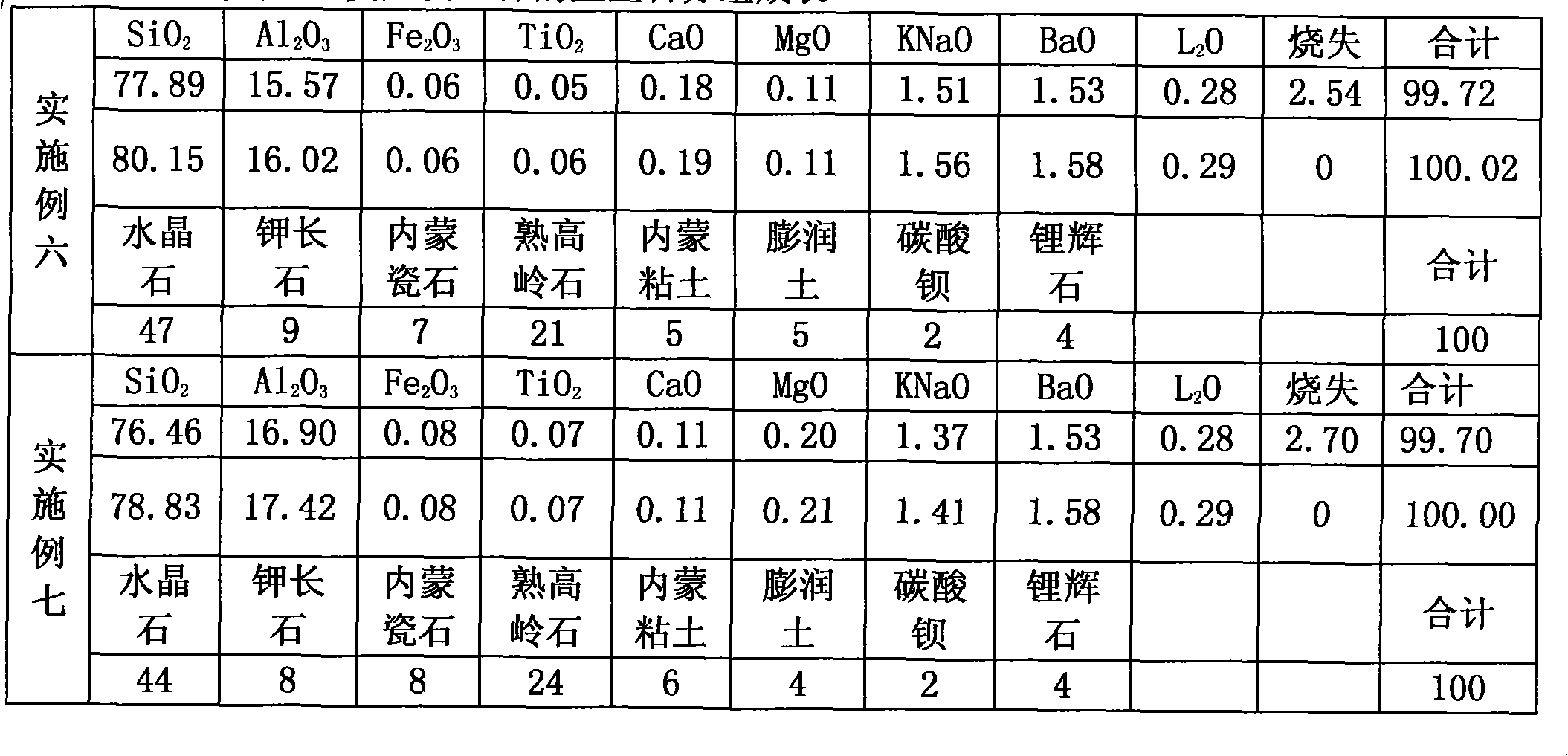

[0023] The chemical composition of the raw materials used in the examples is shown in Table 1, the composition of the body is shown in Table 2, and the biscuit firing temperature range is 1300-1330°C.

[0024] Among them, the crystal stone is pretreated, first calcined at a temperature of 1250-1300 ° C, and then at a weight concentration of 15-20%, such as 15%, 16%, 16.5%, 17%, 17.5%, 18%, 19% or Soak in 20% hydrochloric acid solution for pickling, rinse with water until neutral after pickling, and then grind separately and control the particle size distribution to 5-20 μm. In the bisque firing process, in the temperature range of 500-600°C and 850-950°C, slow heating and cooling are required. The heating rate of slow heating is 10°C / 10 minutes, and the cooling rate of slow cooling is 15°C / 10 minutes.

[0025] The same glaze is applied to the bodies of all the examples, and the glaz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com