Polypropylene fiber reinforced inorganic polymer composite material and preparation method thereof

A technology of inorganic polymers and polypropylene fibers, which is applied in solid waste management, sustainable waste treatment, cement production, etc., can solve the problems of not finding patents on polypropylene bundled monofilament fiber reinforced inorganic polymers, and achieve improvement Flexural strength and compressive strength, the effect of inhibiting the formation and development of cracks, preventing the formation and development of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

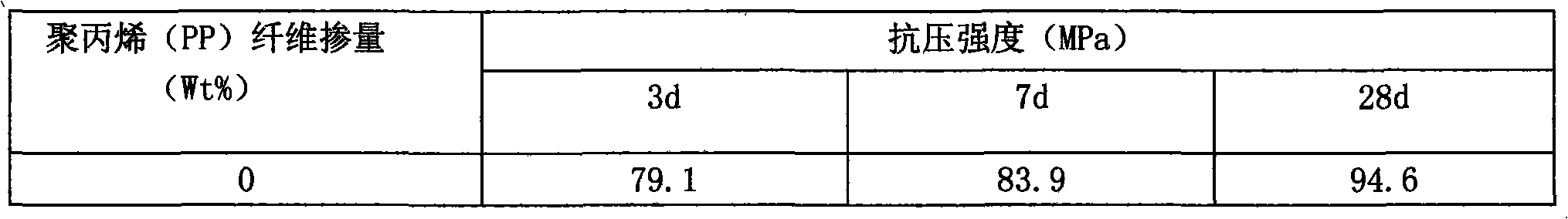

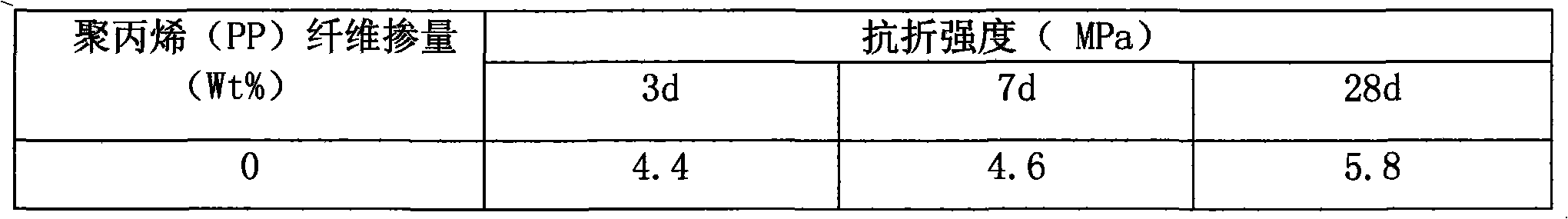

[0110] Accurately weigh 1500g of slag, and use this as the basis of measurement (100%); adopt the external blending method, the dosage of the activator sodium silicate is 11%, and the sodium silicate is dissolved in quantitative water, and the water-slag ratio (w / c)= 0.31. Zero content polypropylene bundled monofilament fibers (for reference). Put the slag into a double-rotation and double-speed slurry mixer for stirring and dispersing; add the sodium silicate aqueous solution and stir; stir at a high speed to form a uniformly mixed slurry, and put the slurry into a 40mm×40mm×160mm iron triple mold. Vibrate on a plastic sand vibrating table and scrape it flat with a scraper to obtain a formed slag-based inorganic polymer composite material. The initial setting time of the sample is 109 minutes, and the final setting time is 332 minutes.

[0111] The molded specimens were cured in a standard curing box for 24 hours, and after demoulding, they were cured in a standard curing b...

Embodiment 2

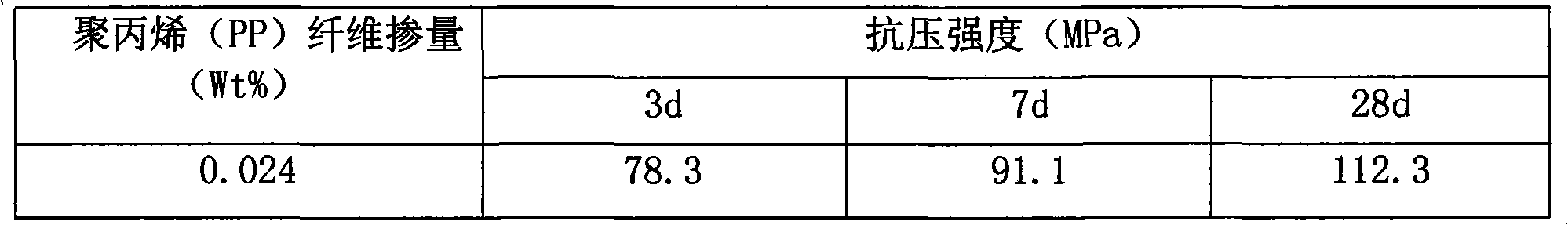

[0117] Accurately weigh 1500g of slag, and use this as the basis of measurement (100%); adopt the external mixing method, and the dosage of activator sodium silicate is 11%; dissolve sodium silicate into quantitative water; water-slag ratio (w / c)= 0.31. The dosage of polypropylene fiber is 0.024%. The polypropylene fiber is pre-dispersed in the slag, and then placed in a double-rotation double-speed pulp mixer for stirring and dispersing; the sodium silicate aqueous solution is added for stirring; high-speed stirring forms a uniformly mixed slurry , The slurry is packed into an iron triple mold of 40mm×40mm×160mm. Vibrate on a plastic sand vibrating table and scrape it flat with a scraper to obtain a formed organic fiber reinforced slag-based inorganic polymer composite material.

[0118] The molded specimens were cured in a standard curing box for 24 hours, and after demoulding, they were cured in a standard curing box for 3 days (3d), 7 days (7d), 28 days (28d) and other di...

Embodiment 3

[0124] All preparation processes are the same as in Example 2. Only change the PP fiber content to 0.036%, the results are shown in Table 5 and Table 6.

[0125] Table 5: Compressive strength of PP fiber reinforced slag-based inorganic polymer composites

[0126]

[0127] Table 6: Flexural strength of PP fiber reinforced slag-based inorganic polymer composites

[0128]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com