Crack control structure of micro-expansion concrete post-cast strip

A technology of micro-expansion concrete and control structure, which is applied in the direction of building structure and construction, and can solve the problems of post-casting belt cracks, corrosion, affecting building applicability, durability and structural safety, and achieve the effect of preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

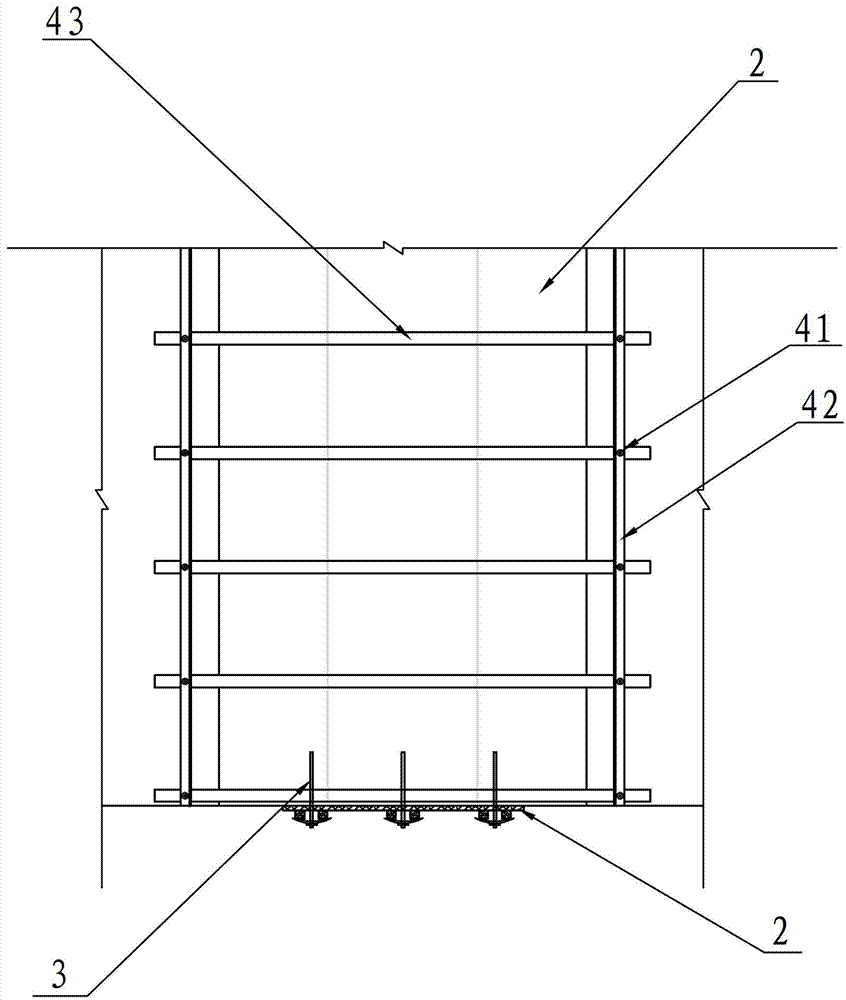

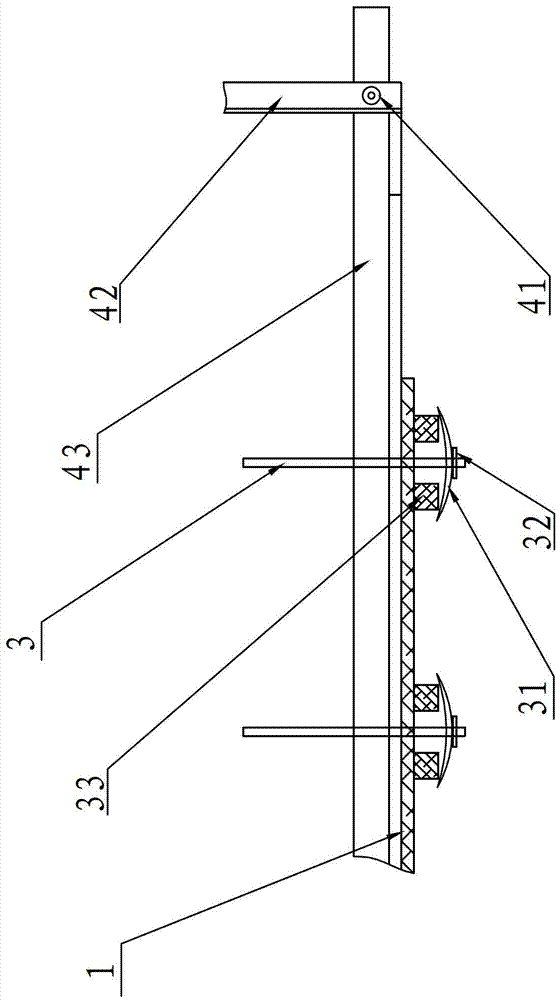

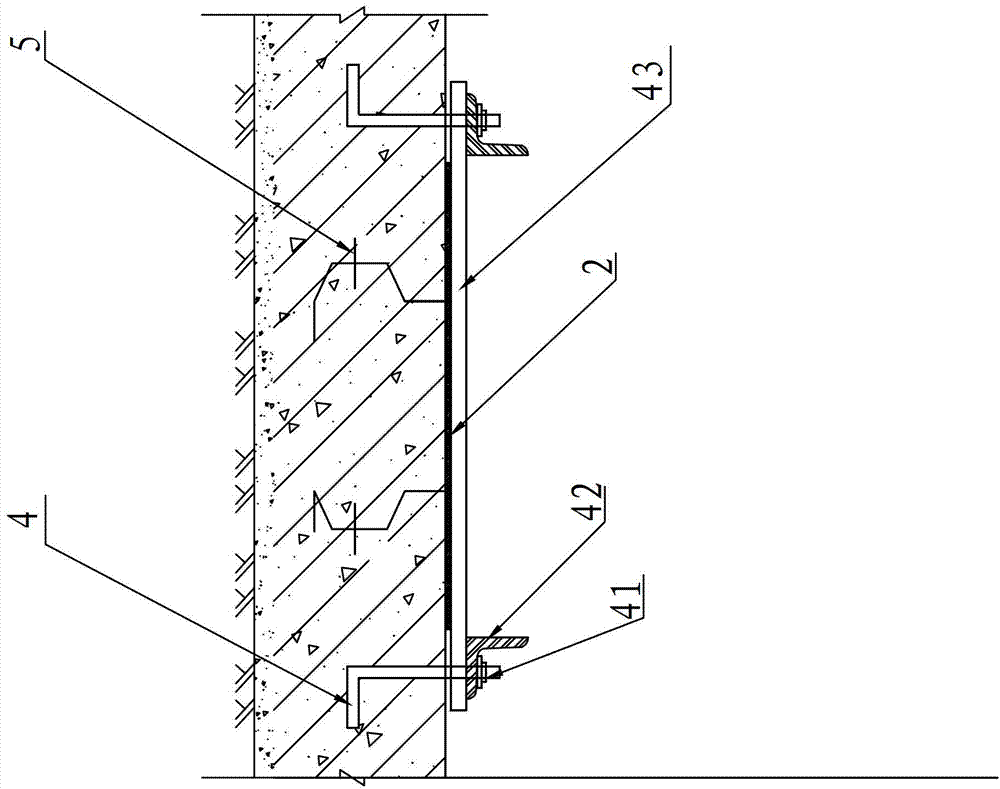

[0020] refer to Figure 1 ~ Figure 3 , the present invention is a micro-expansion concrete post-cast belt crack control structure, including end splints 1 fixedly clamped on both ends of the concrete post-cast belt, and an upper splint 2 is also fixed on the upper surface of the concrete post-cast belt.

[0021] The crack control structure of the micro-expansion concrete post-casting belt is respectively fixed with the end splint 1 and the upper splint 2 on the two ends and the upper surface of the concrete post-casting belt. Constraint, so that it can effectively control the shrinkage of the micro-expansion concrete in the concrete post-casting belt during the dry curing and use stages, and effectively prevent cracks on the concrete post-casting belt.

[0022] As a preferred embodiment of the present invention, the inner side of both ends of the concrete post-casting belt is provided with a number of terminal bolts 3 with one end passing through the terminal splint 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com