Device and process for producing slightly-crumpled insulation paper

A technology for insulating paper and equipment, which is applied in the field of equipment and processes for producing micro-wrinkled insulating paper, can solve the problems of easy breakage of insulating paper, and achieve the effects of improving electrical and chemical properties, improving quality, and increasing longitudinal elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

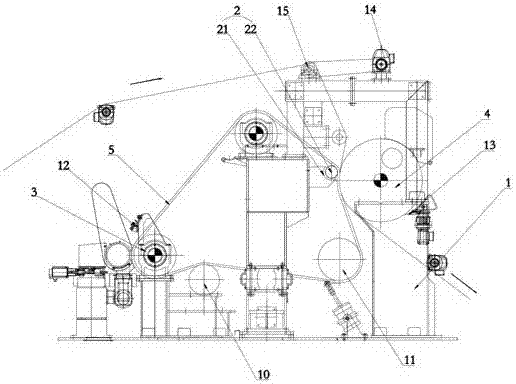

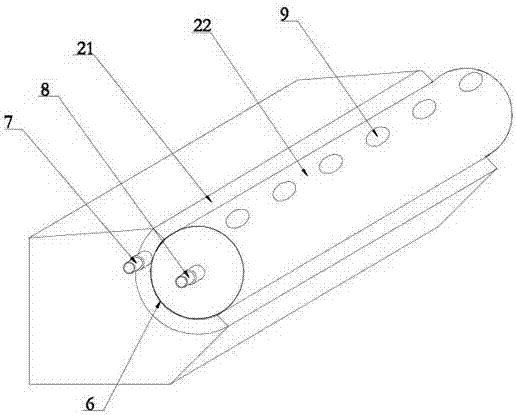

[0029] figure 1 , figure 2 It shows a kind of equipment for producing micro-wrinkled insulating paper provided by the present invention, including a frame 1, an elastic support device 2 fixedly installed on the frame 1, and a rubber blanket conveying roller installed on the frame 1 in rotation 3 and drying cylinder 4; said rubber blanket conveying roller 3 and the elastic support device 2 are commonly wound with a rubber blanket 5, and the elastic support device 2 includes a pneumatic tire 21 installed on the frame 1 and a tire fixed on the pneumatic tire 21 Pressure rod 22, and the surface of pressure rod 22 is bonded to rubber blanket 5, there are at least 3 air tires 21, and multiple air tires 21 are evenly distributed on the two ends of pressure rod 22 and the pressure rod along the axial direction of pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com