Production method of hot-rolled seamless steel pipe billet

A production method and seamless steel pipe technology, applied in the direction of improving process efficiency, etc., can solve the problems that hot-rolled seamless steel pipe blanks cannot meet the direct cold drawing production process, and achieve low yield strength, improved band structure, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

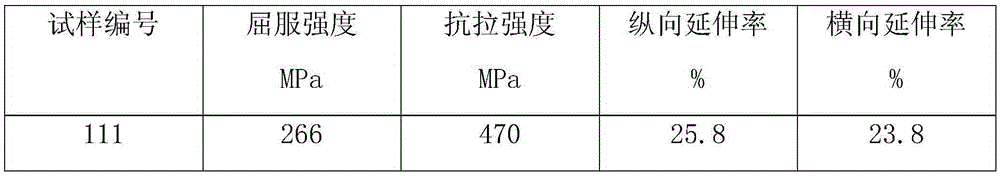

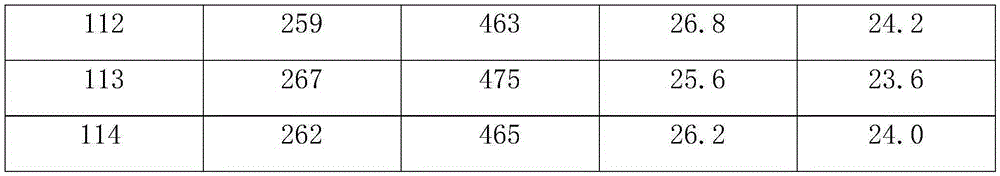

[0040] The production method of the hot-rolled seamless steel pipe billet of the present invention mainly includes the steps of steelmaking, continuous casting, pipe rolling and on-line heat treatment, and the seamless steel pipe billet produced by the hot-rolled seamless steel pipe billet production method is mainly used for production cylinder.

[0041] The production specifications are 159*17 hot-rolled seamless steel pipe blanks for oil cylinders. The chemical composition of the hot-rolled seamless steel pipe blanks for oil cylinders is shown in Table 1 by weight percentage (%), and the balance is Fe and other impurities.

[0042] C Si mn P S Cr Ni Cu

[0043] 0.24 0.28 0.76 0.013 0.014 0.03 0.03 0.06

[0044] Table I

[0045] In the steelmaking step, the step of pre-desulfurizing molten iron is firstly carried out, and then the molten steel is initially smelted in a 70T converter, and the molten iron is fed into the converter f...

Embodiment 2

[0059] The production method of this embodiment is exactly the same as that of Example 1, the only difference is that the specifications of the hot-rolled seamless steel pipe blanks for oil cylinders produced in this embodiment are 168*15 hot-rolled seamless steel pipe blanks for oil cylinders. The chemical composition of the hot-rolled seamless steel pipe blanks for oil cylinders is shown in Table 4 by weight percentage (%), and the balance is Fe and other impurities.

[0060] C Si mn P S Cr Ni Cu 0.25 0.28 0.80 0.012 0.013 0.03 0.03 0.07

[0061] Table four

[0062] In this embodiment, during converter smelting, the carbon content and phosphorus content are controlled during converter tapping, the carbon content is 0.13%, and the phosphorus content is 0.007%. During the alloying operation, the content of each chemical component in the molten steel is adjusted according to the content of each chemical component in the hot-rolled seamless ste...

Embodiment 3

[0069] The production method of this embodiment is exactly the same as that of Example 1, the only difference is that the specification of the hot-rolled seamless steel pipe blank for oil cylinders produced in this embodiment is 139.7*17 hot-rolled seamless steel pipe blanks for oil cylinders, the specification The chemical composition of the hot-rolled seamless steel pipe blanks for oil cylinders is shown in Table 7 by weight percentage (%), and the balance is Fe and other impurities.

[0070] C Si mn P S Cr Ni Cu 0.25 0.30 0.83 0.015 0.014 0.03 0.02 0.06

[0071] Table seven

[0072] In this embodiment, during converter smelting, the carbon content and phosphorus content are controlled when the converter is tapping, and the carbon content is 0.14%, and the phosphorus content is 0.008%. During the alloying operation, adjust the content of each chemical component in the molten steel according to the content of each chemical component in the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com