Preparation method of ultra-thin high-temperature-resistant capacitor film applied to capacitors of electric and hybrid vehicles

A technology for hybrid electric vehicles and capacitors, which is applied to fixed capacitor dielectrics, capacitors, fixed capacitors, etc., can solve the problems of immature high temperature resistant polypropylene capacitor film technology, high temperature resistance performance that cannot meet the requirements of use, and inability to stabilize mass production. , to achieve the effect of low ash content, small thermal shrinkage, and improved film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

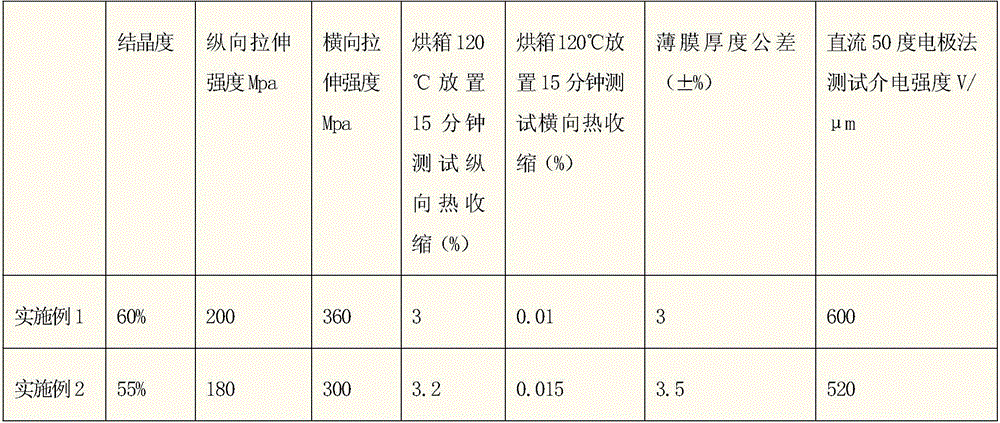

Examples

Embodiment 1

[0027] 1) Raw material preparation: adopt the polypropylene granules of the model HC318BF produced by BOREALLSPOLYMERS. It is required that the isotacticity of the polypropylene raw material (tacticity polymer accounts for the percentage of all polymers) is more than 99%, and the ash content is less than 15ppm. Melt index 3.2-3.7g / 10min, molecular weight distribution coefficient 4.5-5.5 (under humidity 70%, temperature below 35 ℃, dark storage);

[0028] 2) Extrusion by extruder: Put the raw materials in step (1) into the extruder, and the raw materials are melted through the feeding section with a temperature of 230-235°C, the melting section with a temperature of 250-255°C, and the homogenization section with a temperature of 255-260°C Plasticize, then go to the metering pump, pass through the fine filter (the pore size of the filter screen is required to be 15μm), and then extrude through the extruder die (die temperature 230-240°C); the P2 pressure control of the extrusion ...

Embodiment 2

[0037] 1) Raw material preparation: adopt the polypropylene granules of the model HC318BF produced by BOREALLSPOLYMERS. It is required that the isotacticity of the polypropylene raw material (tacticity polymer accounts for the percentage of all polymers) is more than 99%, and the ash content is less than 15ppm. Melt index 3.2-3.7g / 10min, molecular weight distribution coefficient 4.5-5.5 (under humidity 70%, temperature below 35 ℃, dark storage);

[0038] 2) Extrusion by extruder: Put the raw materials in step (1) into the extruder, and the raw materials are melted through the feeding section with a temperature of 240-245°C, the melting section with a temperature of 255-260°C, and the homogenization section with a temperature of 255-260°C Plasticize, then go to the metering pump, pass through the fine filter (the filter screen aperture requires 15μm), and then extrude through the extruder die (die temperature 250-255°C); the pressure of the extrusion system is 65- 70bar (1bar=0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com