Tubular fabric printing and passing mechanism

A printing and cylinder technology, applied in the field of cylindrical weaving printing and spreading mechanism, can solve the problems of low integration, low automation, low production efficiency, etc., and achieve the effect of ensuring smooth transportation, ensuring printing quality, and preventing integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

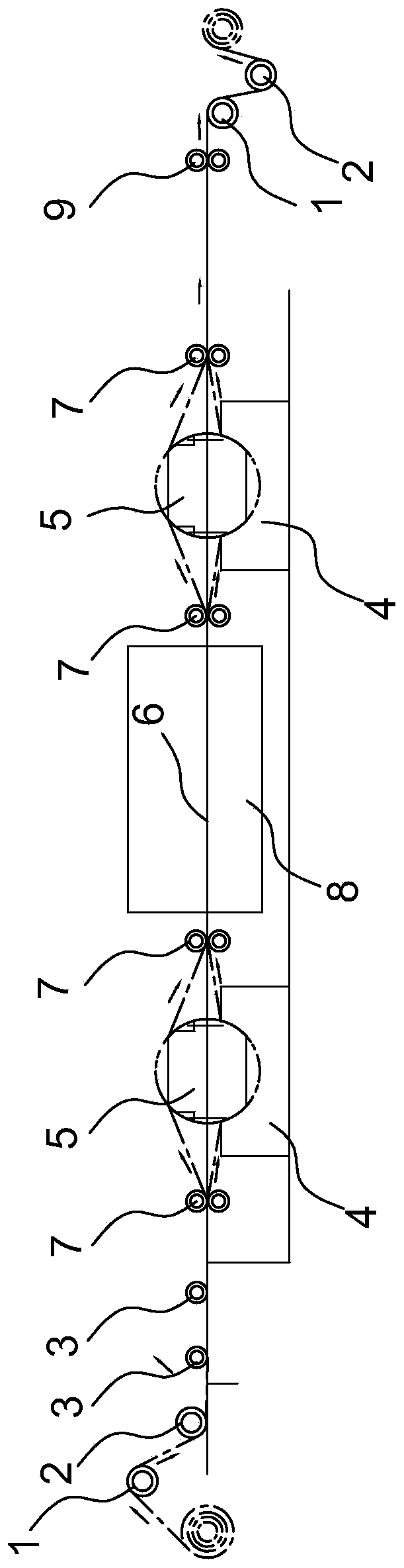

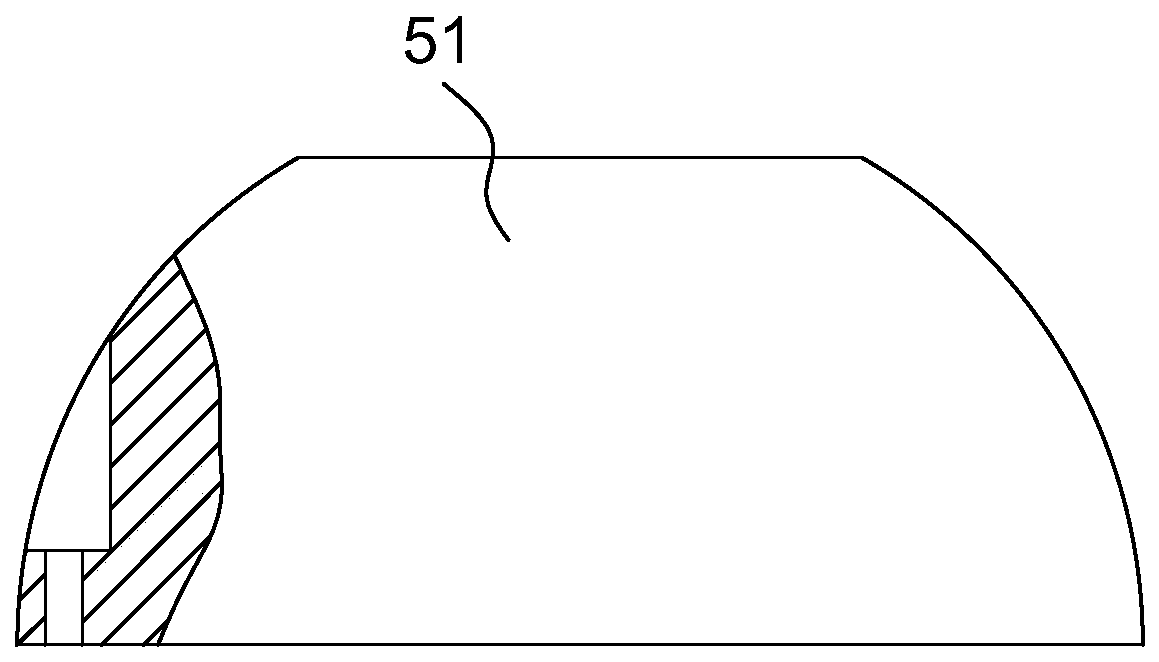

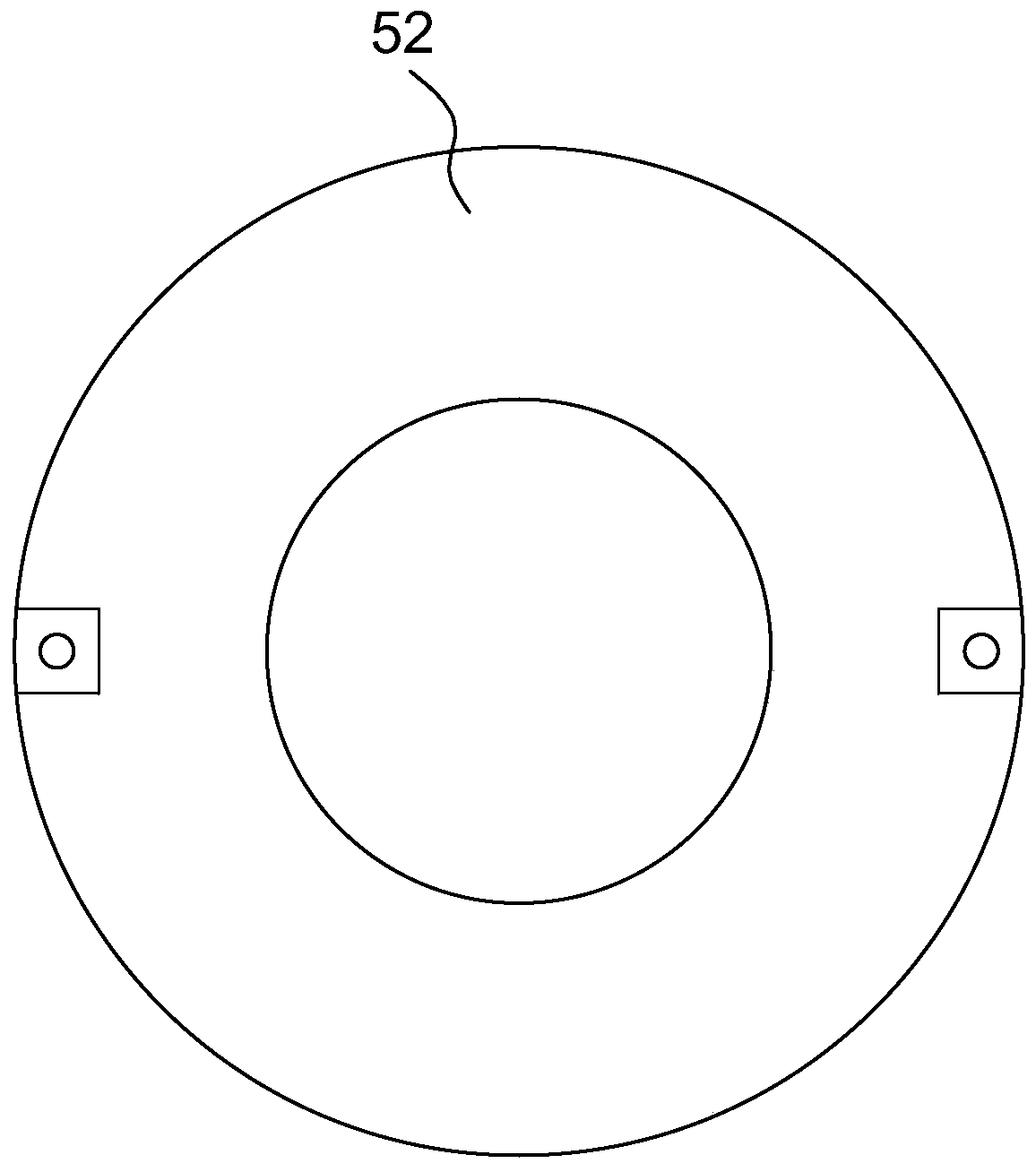

[0031] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , the embodiment of the present invention discloses a circular loom printing machine transmission mechanism, including a frame (not shown in the figure), which is arranged in front of the frame to transfer the circular loom from the cloth roll to the printing area 8 and the transmission roller 1 which is arranged at the rear of the frame and is used to transport the printed cylindrical woven fabric to the next process, and the printing area 8 is provided with a printing machine for double-sided printing of the cylindrical woven fabric (the present invention The printing machine mentioned in is a known technology, and it can be referred to a new double-sided printing machine for textile fabrics disclosed in Chinese Patent Publication No. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com