Low-color-difference polyester differential shrinkage composite yarn and preparation method thereof

A different shrinkage and composite yarn technology, which is applied in the direction of single-component polyester rayon, dyeing method, rayon manufacturing, etc., can solve the problems of troublesome dyeing and post-processing, not easy to wash off, hindering liquid flow circulation, etc. Achieve the effects of eliminating aurora defects, excellent dyeing performance, and excellent shading performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

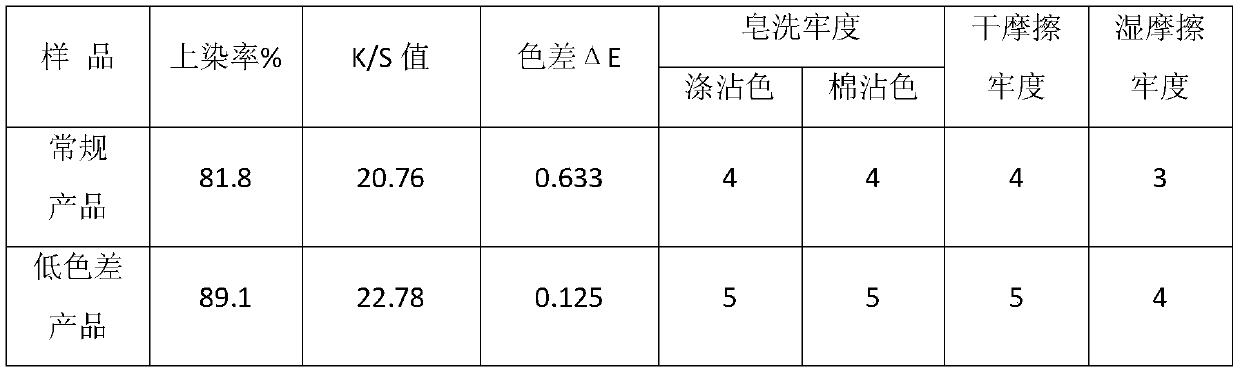

Embodiment 1

[0071] A method for preparing low-chromatic-difference polyester different-shrinkage composite yarn, the main process comprising:

[0072] (1) Preparation of catalyst magnesium ethylene glycol:

[0073] Add ethylene glycol into the single-chamber electrolytic cell, the supporting electrolyte is magnesium chloride, the metal magnesium block is the anode, and the cathode is graphite; connect direct current, the initial voltage is 6V, the cathode current density is 150mA, and electrolyze for 10 hours at 50°C. Take out the electrode to obtain a white suspension; filter under reduced pressure, wash the white solid with absolute ethanol, and dry to obtain magnesium ethylene glycol;

[0074] (2) Preparation of polyester, including esterification reaction and polycondensation reaction:

[0075] Esterification reaction:

[0076] Use terephthalic acid and ethylene glycol as raw materials, the molar ratio of ethylene glycol to terephthalic acid is 1.2:1, add anti-ether agent sodium ace...

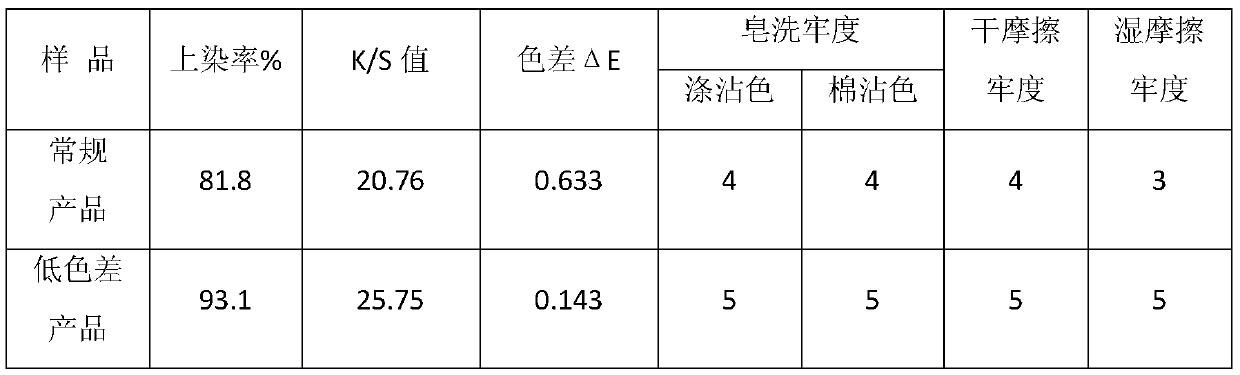

Embodiment 2

[0097] A method for preparing low-chromatic-difference polyester different-shrinkage composite yarn, the main process comprising:

[0098] (1) Preparation of catalyst magnesium ethylene glycol:

[0099] Add ethylene glycol into the single-chamber electrolytic cell, the supporting electrolyte is magnesium chloride, the metal magnesium block is the anode, and the cathode is graphite; connect direct current, the initial voltage is 10V, the cathode current density is 200mA, electrolyze at 60°C for 12 hours, after the electrolysis ends Take out the electrode to obtain a white suspension; filter under reduced pressure, wash the white solid with absolute ethanol, and dry to obtain magnesium ethylene glycol;

[0100] (2) Preparation of polyester, including esterification reaction and polycondensation reaction:

[0101] Esterification reaction:

[0102] Using terephthalic acid and ethylene glycol as raw materials, the molar ratio of ethylene glycol to terephthalic acid is 2.0:1, adding...

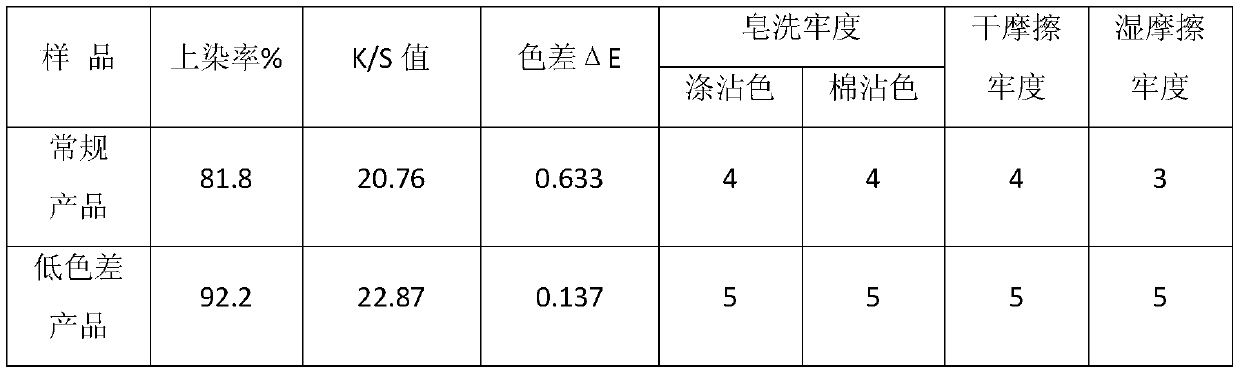

Embodiment 3

[0123] A method for preparing low-chromatic-difference polyester different-shrinkage composite yarn, the main process comprising:

[0124] (1) Preparation of catalyst magnesium ethylene glycol:

[0125] Add ethylene glycol into the single-chamber electrolytic cell, the supporting electrolyte is magnesium chloride, the metal magnesium block is the anode, and the cathode is graphite; connect direct current, the initial voltage is 7V, the cathode current density is 160mA, and electrolyze for 11 hours at 55°C. Take out the electrode to obtain a white suspension; filter under reduced pressure, wash the white solid with absolute ethanol, and dry to obtain magnesium ethylene glycol;

[0126] (2) Preparation of polyester, including esterification reaction and polycondensation reaction:

[0127] Esterification reaction:

[0128] Using terephthalic acid and ethylene glycol as raw materials, the molar ratio of ethylene glycol to terephthalic acid is 1.5:1, adding anti-ether agent sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| coefficient of variation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com