A kind of low color difference polyester imitation cotton type differential shrinkage composite yarn and its preparation method

A composite yarn and different shrinkage technology, which is applied in the direction of single-component polyester rayon, melt spinning, etc., can solve the problem of increased air content in PET different shrinkage mixed fiber composite yarn fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

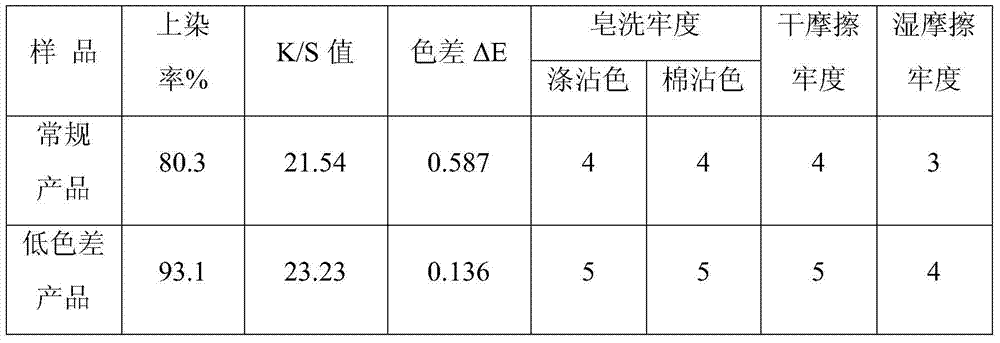

Embodiment 1

[0085] A preparation method of a low-chromatic-difference polyester imitation cotton type different shrinkage composite yarn, the main process includes:

[0086] (1) Preparation of catalyst magnesium ethylene glycol:

[0087] Add ethylene glycol into the single-chamber electrolytic cell, the supporting electrolyte is magnesium chloride, the metal magnesium block is the anode, and the cathode is graphite; connect direct current, the initial voltage is 6V, the cathode current density is 150mA, and electrolyze for 10 hours at 50°C. Take out the electrode to obtain a white suspension; filter under reduced pressure, wash the white solid with absolute ethanol, and dry to obtain magnesium ethylene glycol;

[0088] (2) Preparation of polyester, including esterification reaction and polycondensation reaction:

[0089] Esterification reaction:

[0090] Using terephthalic acid and ethylene glycol as raw materials, the molar ratio of ethylene glycol to terephthalic acid is 1.2:1, adding...

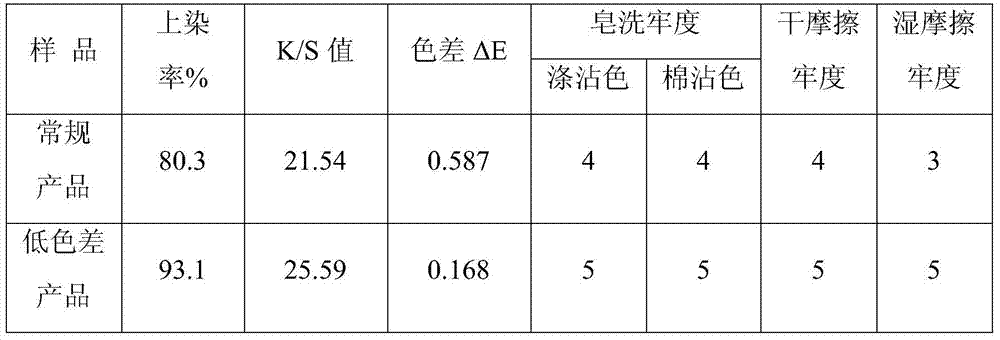

Embodiment 2

[0124] A preparation method of a low-chromatic-difference polyester imitation cotton type different shrinkage composite yarn, the main process includes:

[0125] (1) Preparation of catalyst magnesium ethylene glycol:

[0126] Add ethylene glycol into the single-chamber electrolytic cell, the supporting electrolyte is magnesium chloride, the metal magnesium block is the anode, and the cathode is graphite; connect direct current, the initial voltage is 10V, the cathode current density is 200mA, electrolyze at 60°C for 12 hours, after the electrolysis ends Take out the electrode to obtain a white suspension; filter under reduced pressure, wash the white solid with absolute ethanol, and dry to obtain magnesium ethylene glycol;

[0127] (2) Preparation of polyester, including esterification reaction and polycondensation reaction:

[0128] Esterification reaction:

[0129] Using terephthalic acid and ethylene glycol as raw materials, the molar ratio of ethylene glycol to terephtha...

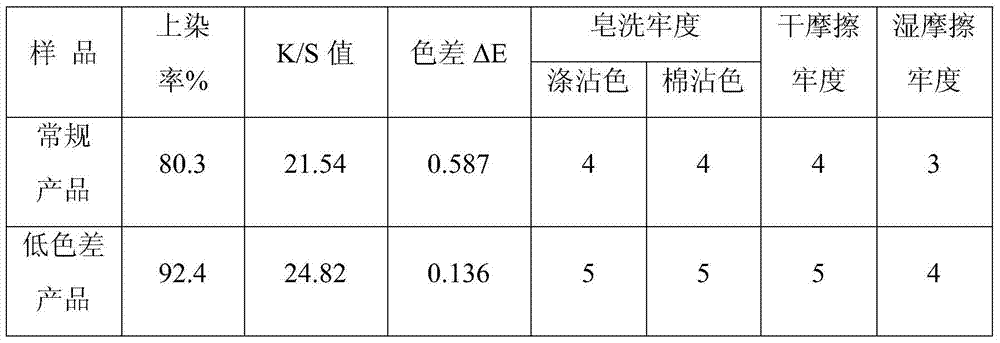

Embodiment 3

[0163] A preparation method of a low-chromatic-difference polyester imitation cotton type different shrinkage composite yarn, the main process includes:

[0164] (1) Preparation of catalyst magnesium ethylene glycol:

[0165] Add ethylene glycol into the single-chamber electrolytic cell, the supporting electrolyte is magnesium chloride, the metal magnesium block is the anode, and the cathode is graphite; connect direct current, the initial voltage is 7V, the cathode current density is 160mA, and electrolyze for 11 hours at 55°C. Take out the electrode to obtain a white suspension; filter under reduced pressure, wash the white solid with absolute ethanol, and dry to obtain magnesium ethylene glycol;

[0166] (2) Preparation of polyester, including esterification reaction and polycondensation reaction:

[0167] Esterification reaction:

[0168] Using terephthalic acid and ethylene glycol as raw materials, the molar ratio of ethylene glycol and terephthalic acid is 1.5:1, addin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com