A process for thickening hand feeling of polyester printed fabric

A printing and fabric technology, which is applied in the processing of textile materials, textile processing machine accessories, knitting, etc., can solve the problems of hard hand feeling, unsatisfactory coloring rate, and insufficient penetration of dye liquor, so as to achieve uniform dyeing and ensure uniform dyeing. Good dyeing performance and coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

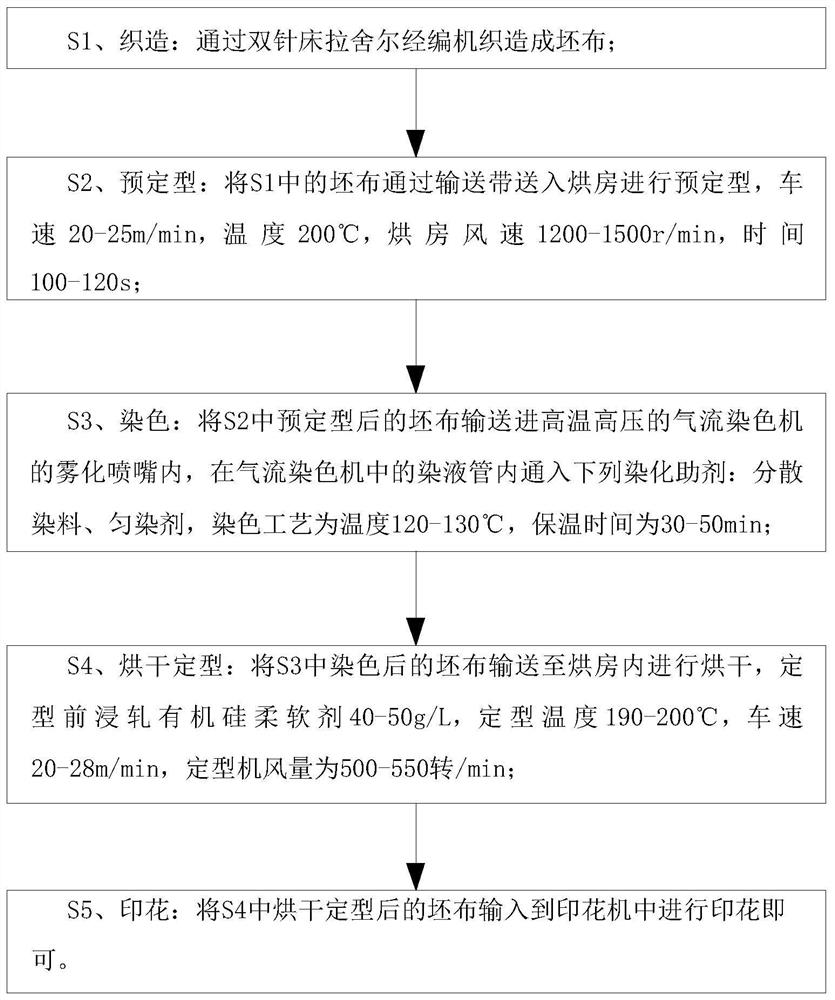

Method used

Image

Examples

Embodiment approach

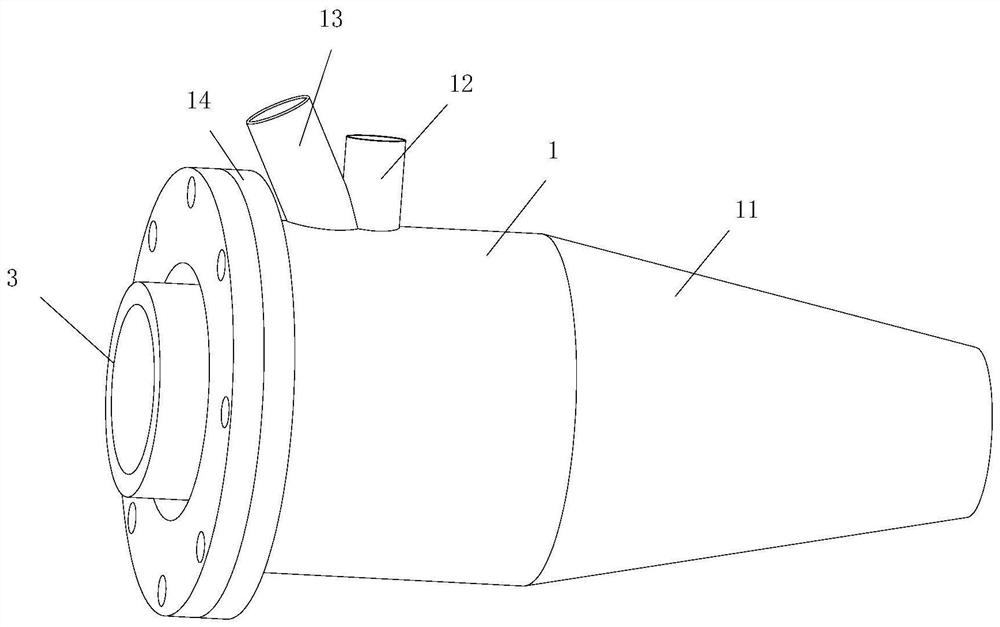

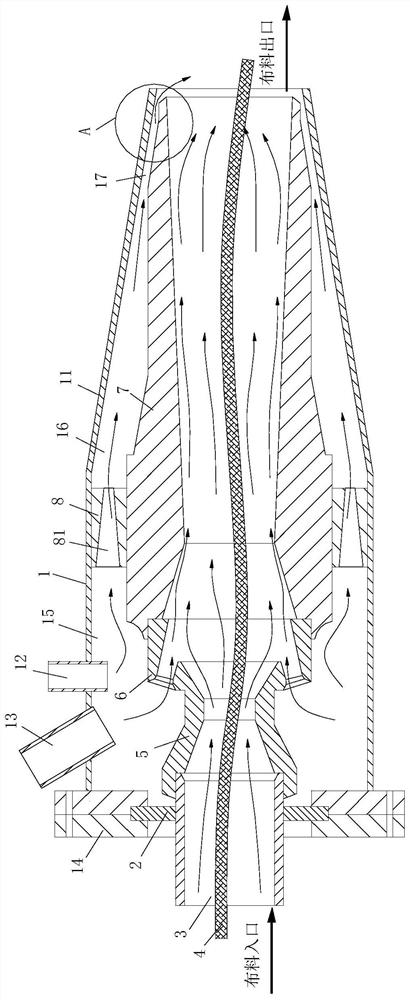

[0041] As an embodiment of the present invention, the nozzle body 7 is a Laval nozzle structure, wherein the left side of the first gas-liquid passage is a converging section, the right side of the first gas-liquid passage is an expanding section, and the converging section and the junction of the expansion section constitutes the throat. By adopting the Laval nozzle structure for the nozzle body 7, the high-speed air flow from the outlet at the end of the expansion section can have a faster speed while the high-speed air flow rate in the converging section remains unchanged, thereby reducing energy consumption without increasing energy consumption. Under the circumstance of better pulling the grey fabric 4 forward, avoid the grey fabric 4 from blocking the folds, and at the same time, the high-speed airflow in the expansion section is faster, which can also make the atomized dye solution of the first dyeing better atomized; the atomized dye solution Under the impact of the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com