Economical dispersion dye mixture

A technology of disperse dyes and mixtures, which is applied in the direction of organic dyes, etc., can solve the problems of high price, less supply of disperse dyes, and inability to meet large-scale production, and achieve low production costs, suitable for large-scale production, and easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

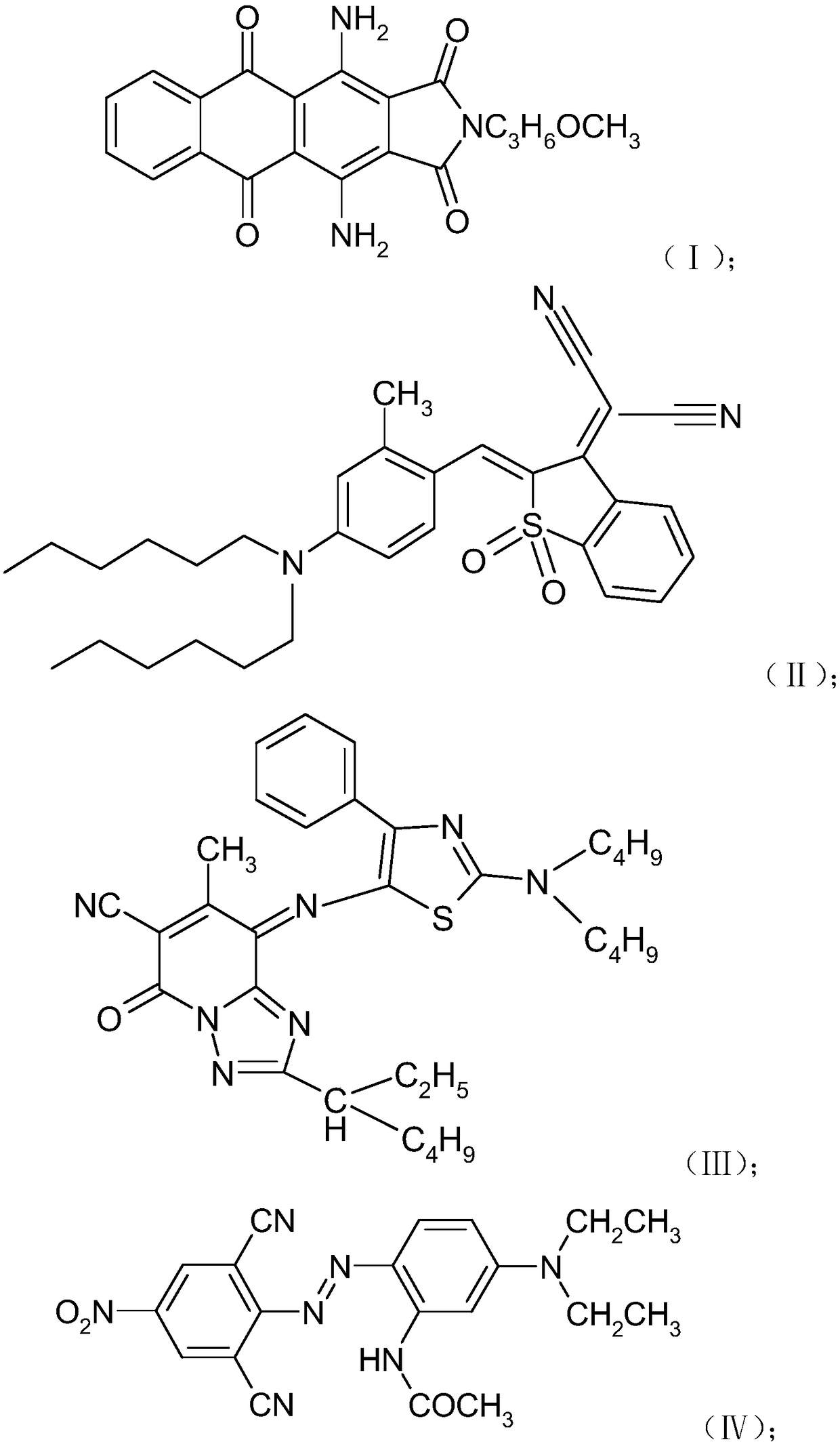

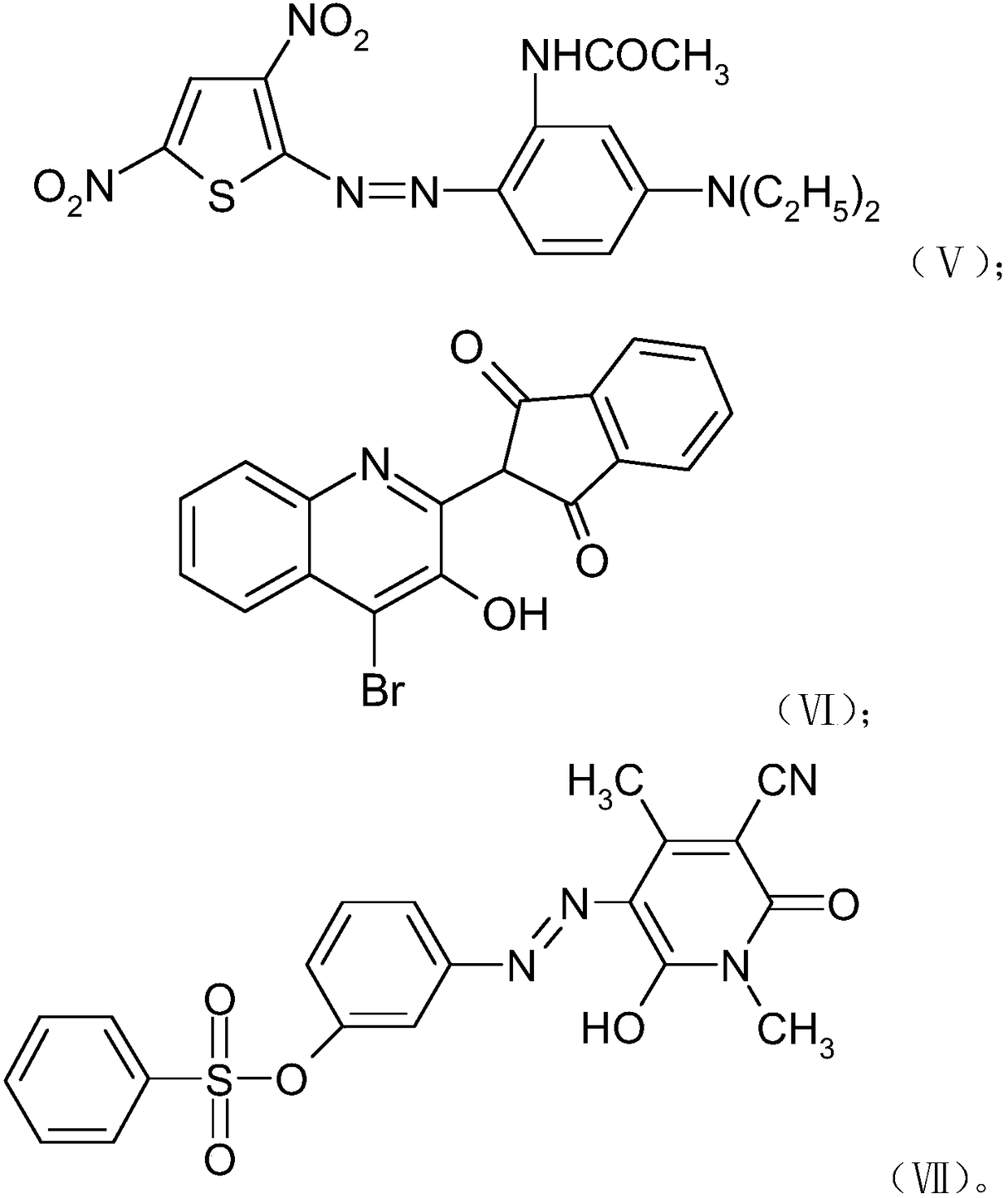

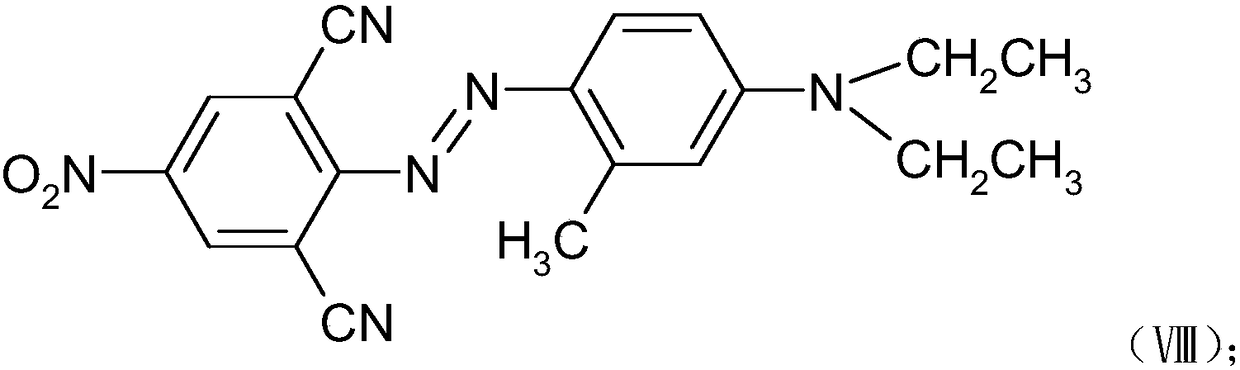

Image

Examples

Embodiment 1~20

[0019] Embodiments 1-20: An economical disperse dye mixture. Take the components in parts by weight shown in Table 1, add water and stir evenly, grind and disperse with a grinder, then filter and spray dry to obtain the finished product.

[0020] Components and parts by weight information statistics of a kind of economical disperse dye mixture of Table 1 Embodiment 1~20 (unit: part)

[0021]

[0022]

[0023] With reference to Example 1 disclosed by the patent with the authorized announcement number CN105860581A, take 0.1g of C.I. Disperse Blue 60, 20g of C.I. Disperse Green 9, 5g of C.I. Disperse Blue 354, 0.5g of C.I. Add water and stir well with Huang 211, 0.1g aromatic sulfonic acid condensate, 0.01g CT powder and 0.01g microcrystalline cellulose, grind and disperse with a grinder, filter and spray dry to obtain control sample 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com