A dyeing process of flame-retardant blended fiber

A blended fiber and process technology is applied in the field of dyeing technology of flame-retardant blended fibers, which can solve the problems of difficulty in dyeing and dyeing of flame-retardant blended fibers, and achieve the effects of clean production, reduction of dye residues, and improvement of utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

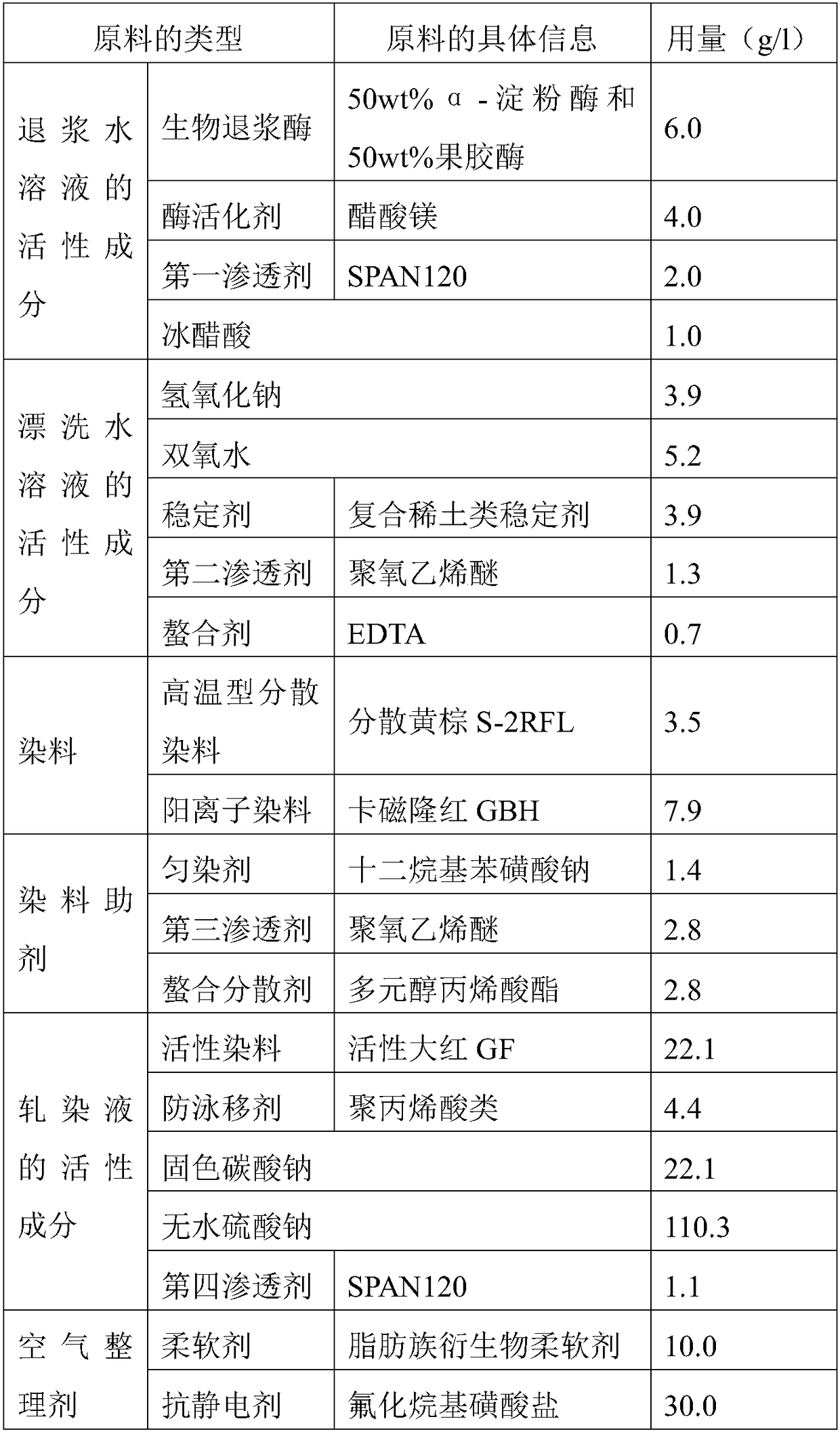

[0029] Flame-retardant blended fiber A kind of dyeing process of flame-retardant blended fiber, it comprises the following steps:

[0030] Step 1, desizing treatment: Add the flame-retardant blended fiber to the desizing aqueous solution at 50-60 ° C, keep it warm for 10-24 hours, and then wash it with water at 50-70 ° C to remove the surface residue;

[0031] Step 2, rinsing treatment: take the flame-retardant blended fiber treated in step 1, add it to the rinsing aqueous solution at 95-100°C, keep it warm for 0.5-2hr, and then wash at 50-70°C to remove the surface residue;

[0032] Step 3, depilation treatment: take the flame-retardant blended fiber treated in step 2, and remove the surface hairiness;

[0033] Step 4, the first dyeing treatment: take the flame-retardant blended fiber treated in step 3, add it to 15-35°C water, gradually raise the temperature of the water bath to 100-102°C, and add dye when the water bath is 68-71°C And when the water bath is 95-100°C, add d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com