Disperse dye composition and preparing method thereof

A technology of disperse dyes and compositions, applied in the direction of organic dyes, etc., which can solve the problems of few sources of supply, high cost, and inability to meet the needs of large-scale production, and achieve good color fastness to light, easy control, and increased actual relative strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0036] Embodiment 1-9: A disperse dye composition, obtained by mixing the components in parts by weight shown in Table 1.

[0037] Table 1 Components and parts by weight information statistics of a kind of disperse dye composition of embodiment 1-9 (unit: part)

[0038]

Embodiment 10-15

[0039] Embodiment 10-15: a kind of disperse dye composition, it is prepared by following method:

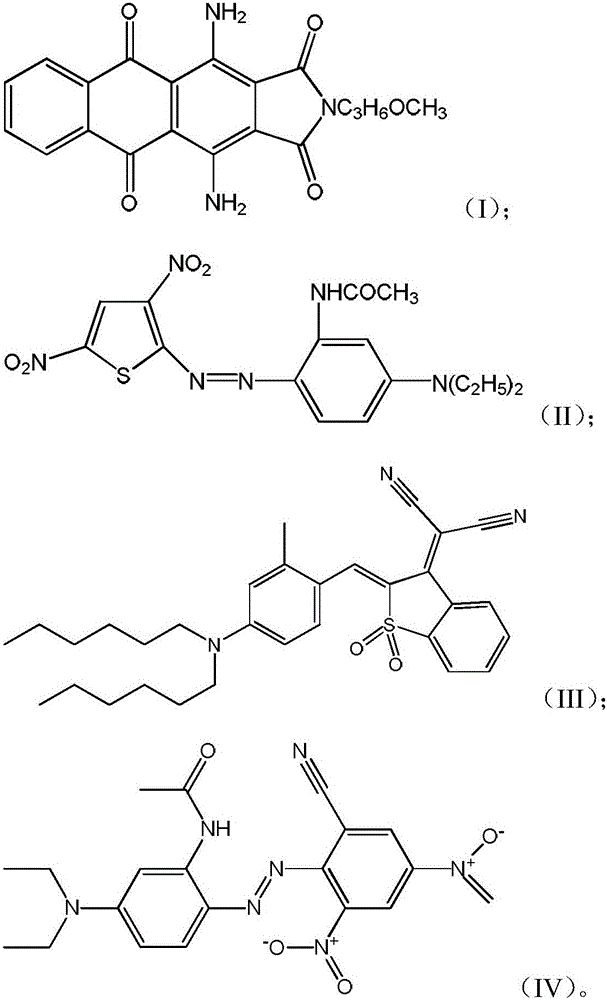

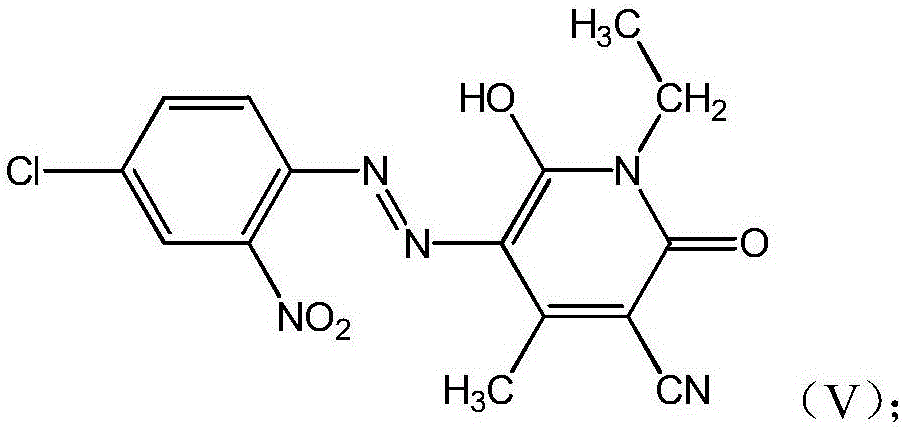

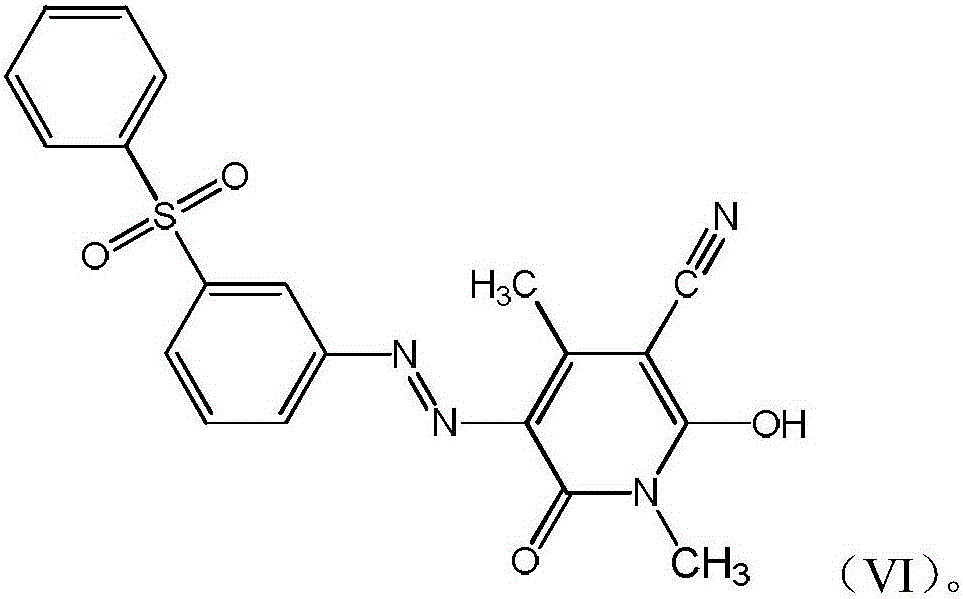

[0040] Step 1: Take the C.I. Disperse Blue 60 shown in Formula I, the C.I. Disperse Green 9 shown in Formula II, the C.I. Disperse Blue 354 shown in Formula III, and the C.I. Disperse Blue 165 shown in Formula IV. , disperse yellow, mixed to obtain mixed dyes; wherein, the disperse yellow is selected from C.I. disperse yellow 211 shown in formula V and / or C.I. disperse yellow 114 shown in formula VI;

[0041] Step 2: Add water or ethanol aqueous solution to the mixed dye obtained in step 1, and stir evenly to obtain a mixed slurry; take the formula amount auxiliary agent, add water or ethanol aqueous solution to make a solution, and slowly add the prepared solution to the above stirring state In the mixed slurry below, stir evenly; wherein, the weight ratio of mixed dye and water is 1:2~20, the weight ratio of ethanol and water is 1:20~50, and the auxiliary agent is selected from...

Embodiment 16-18

[0044] Embodiment 16-18: a kind of preparation method of disperse dye composition, comprises the steps:

[0045] Step 1: Take the C.I. Disperse Blue 60 shown in Formula I, the C.I. Disperse Green 9 shown in Formula II, the C.I. Disperse Blue 354 shown in Formula III, and the C.I. Disperse Blue 165 shown in Formula IV. , Disperse Yellow, mixed to obtain a mixed dye; wherein, the Disperse Yellow is selected from C.I. Disperse Yellow 211 as shown in Formula V and / or C.I. Disperse Yellow 114 as shown in Formula VI;

[0046] Step 2: Add water or an aqueous ethanol solution to the mixed dye obtained in step 1, and stir evenly to obtain a mixed slurry, wherein the weight ratio of the mixed dye to water is 1:2 to 20, and the weight ratio of ethanol to water is 1: 20~50;

[0047] Step 3: Spray-dry the mixed slurry obtained in Step 2 to obtain;

[0048] Wherein, each component and consumption amount thereof are as shown in Table 2 in the embodiment 16-18.

[0049] Table 2 Components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com