Method for weaving olefine environmentally-friendly cloth

An orifen, environmentally friendly technology, applied in textiles, papermaking, textiles, fabrics, etc., can solve the problems of fracture resistance, color fastness to washing, color fastness to rubbing, color fastness to light, and environmental performance. , to achieve good color fastness to light, rapid biodegradation, and strong anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

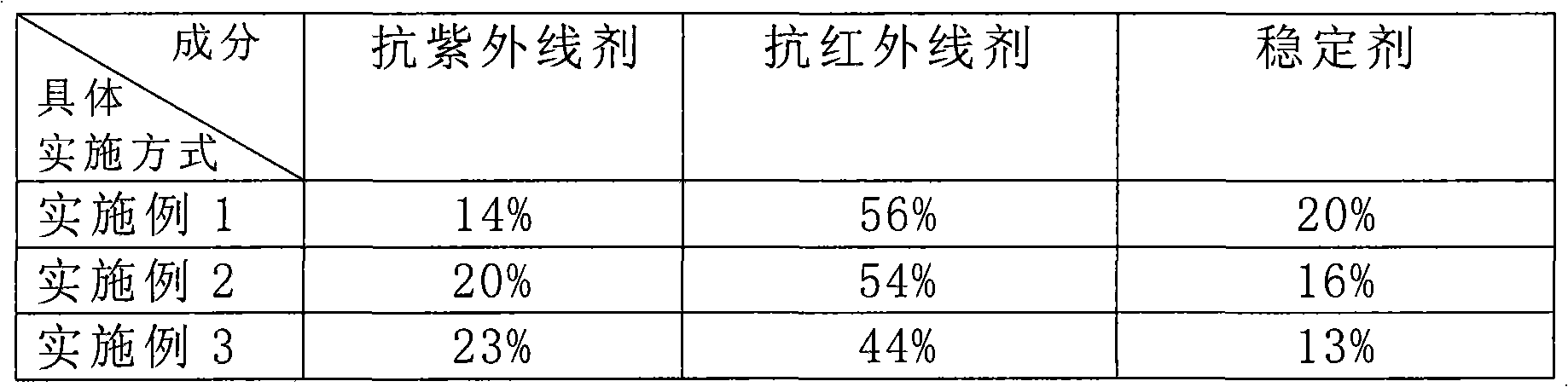

[0029] Put the raw materials in the ratio described in Example 1 in Table 1 into a vibrating mixer and mix for 30 to 60 minutes to break up the agglomerates in the raw materials and make the mixing more uniform. Then use a mold compact to place it in a crucible and calcinate at 1500°C for 1-2 hours, and then pulverize after cooling to form a mixed anti-aging agent powder with a particle size of 5-15 μm.

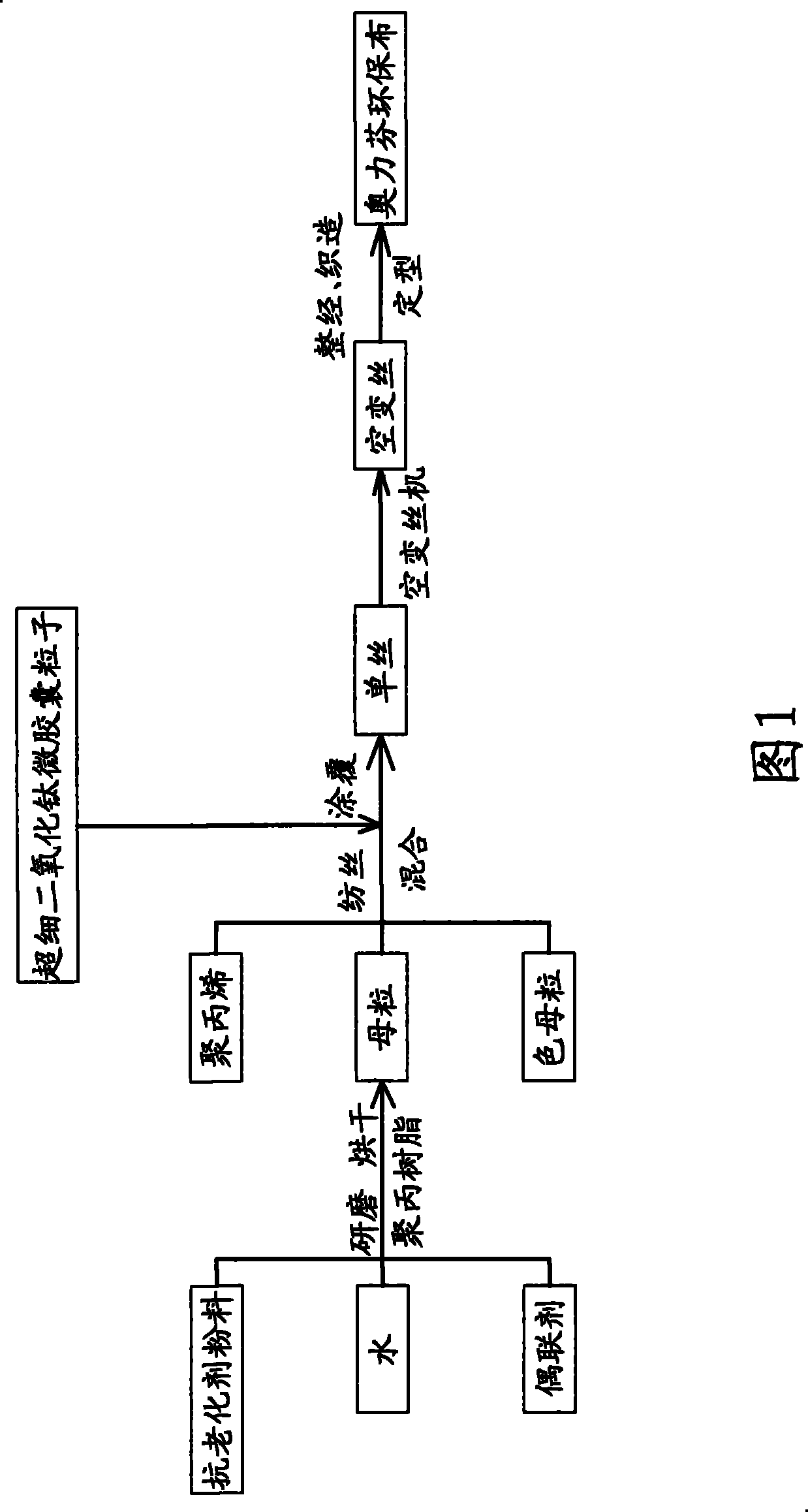

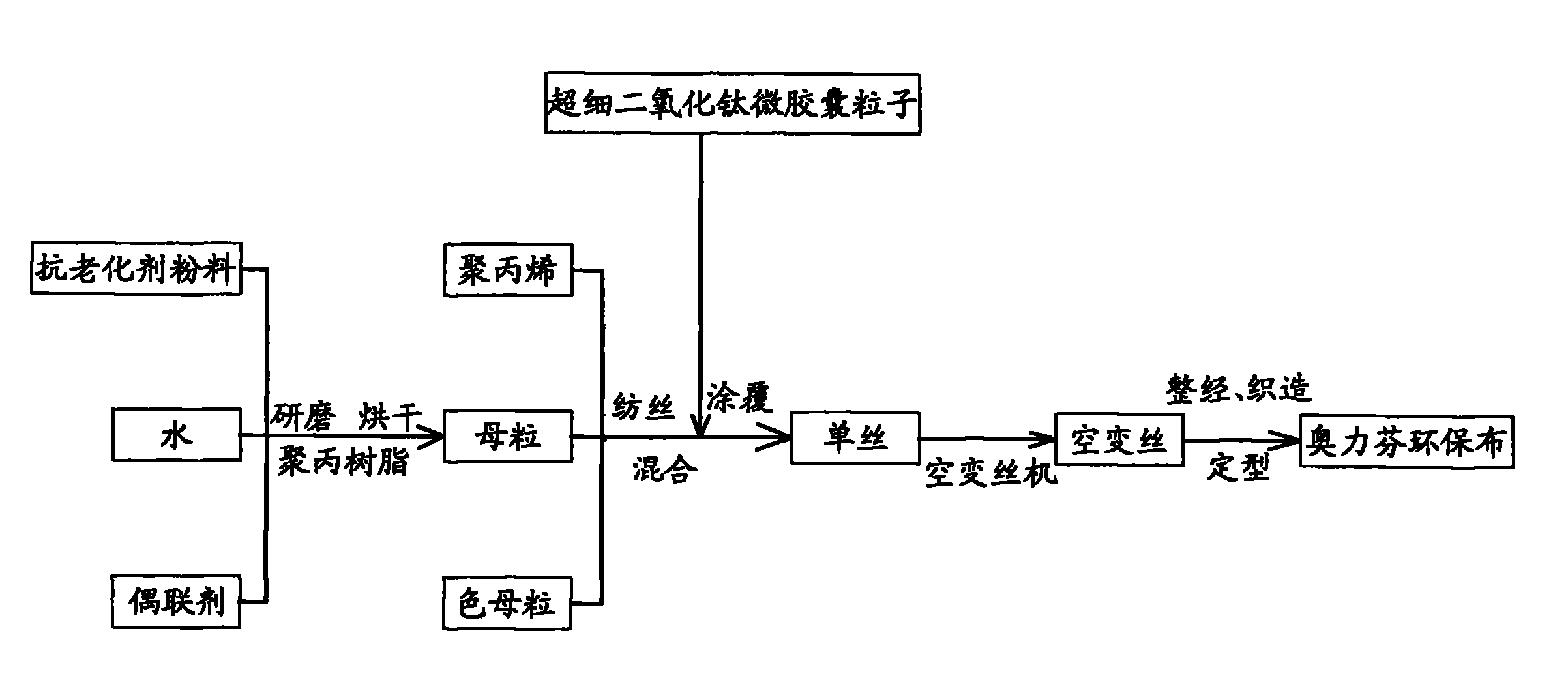

[0030] As shown in the process flow diagram of Fig. 1: anti-aging agent powder, water and silane coupling agent vinyltriethoxysilane are added to the grinder in a weight ratio of 100: 100: 2 and ground for 108 hours, Make it into a pre-dispersed powder with a powder size of less than 1 μm, and then dry it;

[0031] The dried anti-aging agent powder and polypropylene resin are mixed by 80%: 20% by weight and entered into an automatic feeder to extrude with a mixing type co-rotating twin-screw extruder at a speed of 70kg / h, and open the vacuum blower. The air device extracts t...

Embodiment 2

[0036] Put the raw materials in the ratio described in Example 2 in Table 1 into a vibrating mixer and mix for 30 to 60 minutes to break up the agglomerates in the raw materials and make the mixing more uniform. Then use a mold compact to place it in a crucible and calcinate at 1600°C for 1-2 hours, and then pulverize after cooling to form a mixed anti-aging agent powder with a particle size of 5-15 μm.

[0037] Put the anti-aging agent powder, water and silane coupling agent vinyltrimethoxysilane into the grinder according to the weight ratio of 100:90:3, and grind for 72 hours to form a pre-divided powder with a powder size of less than 1 μm. Loose powder, then dry.

[0038] The dried anti-aging agent powder and polypropylene resin are mixed by 70%: 30% by weight and entered into an automatic feeder to extrude with a mixing type co-rotating twin-screw extruder at a speed of 70kg / h, and open the vacuum degassing machine. The air device extracts the moisture in the material, ...

Embodiment 3

[0041] Put the raw materials in the ratio described in Example 3 in Table 1 into a vibrating mixer and mix for 30 to 60 minutes to break up the agglomerates in the raw materials and make the mixing more uniform. Then use a mold compact to place it in a crucible for calcination at a temperature of 1550° C. for 1 to 2 hours, and then pulverize it after cooling to form a mixed anti-aging agent powder with a particle size of 5 to 15 μm.

[0042] Add anti-aging agent powder, water and silane coupling agent vinyltriethoxysilane into the grinder in a weight ratio of 100:80:5 and grind for 128 hours to form a pre-prepared powder with a powder size of less than 1 μm. Disperse the powder and then dry it;

[0043] The dried anti-aging agent powder and polypropylene resin are mixed by 75%: 25% by weight and entered into an automatic feeder to extrude with a mixing type co-rotating twin-screw extruder at a speed of 70kg / h, and open the vacuum degassing machine. The air device extracts the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com