Bio-oil-based anti-ageing asphalt regenerant and preparation method thereof

A kind of technology of asphalt rejuvenator and anti-aging agent, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of asphalt bio-rejuvenating agent aging easily, achieve good anti-aging ability, improve low-temperature performance, and improve the preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

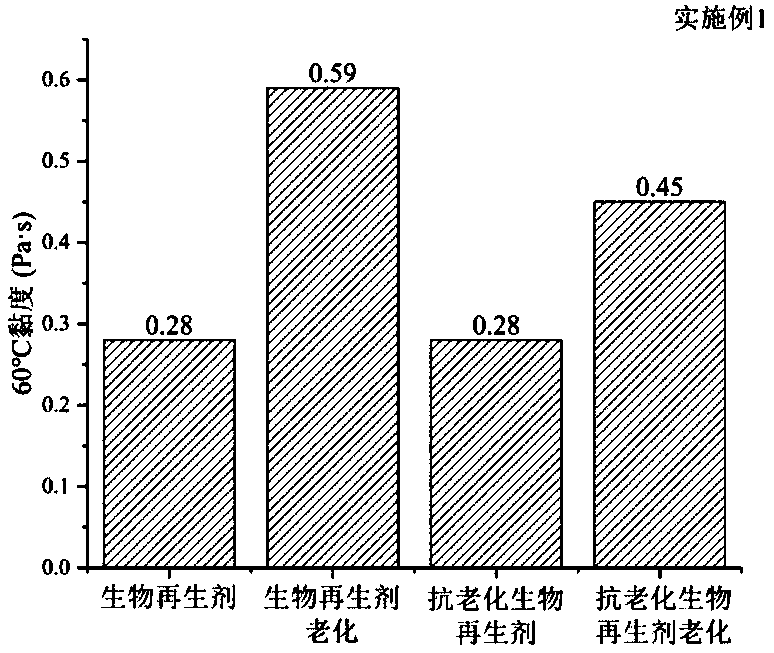

Embodiment 1

[0029] A bio-oil-based anti-aging asphalt regenerant and a preparation method thereof, comprising the steps of:

[0030] 1) Its components and mass percentage content are: bio-oil (epoxy vegetable oil) is 88.5%, dibutyl phthalate is 7.5%, anti-aging agent A (tert-butyl hydroquinone TBHQ) is 3.0% , antiaging agent B (zinc dialkyldithiophosphate ZDDP) is 1.0% (as the biological regeneration agent component and mass percentage content of not adding antiaging agent as contrast: biological oil (epoxy vegetable oil) is 92.5% , dibutyl phthalate is 7.5%);

[0031] 2) Put the bio-oil into the reaction vessel, control the constant temperature, the temperature is about 100°C, stir with the shearer at a low speed for 15-30min, and the stirring speed is about 60r / min, and add the plasticizer collar according to the determined mass percentage while stirring Dibutyl phthalate, initially produced biological regeneration agent;

[0032]3) Put the biological regeneration agent prepared in 2)...

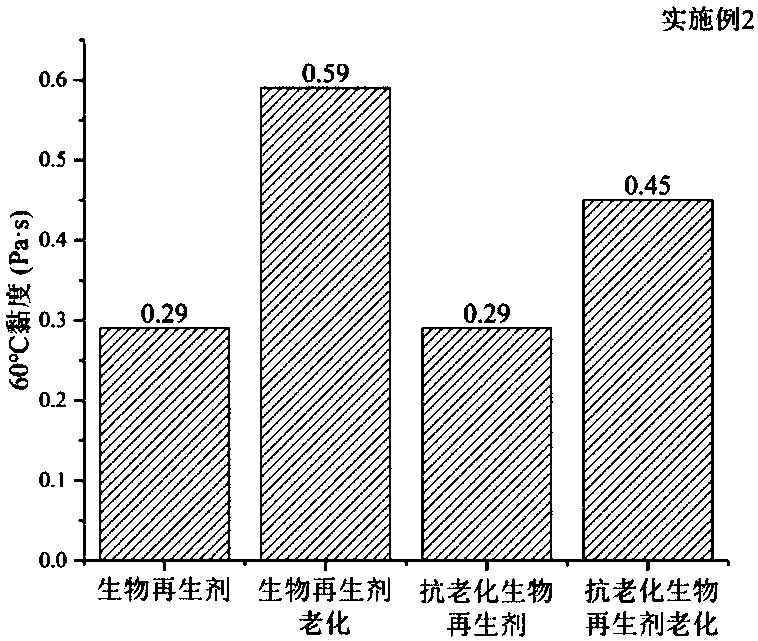

Embodiment 2

[0044] A bio-oil-based anti-aging asphalt regenerant and a preparation method thereof, comprising the steps of:

[0045] 1) Its components and mass percentage content are: bio-oil (epoxy vegetable oil) is 88.0%, dibutyl phthalate is 8.0%, anti-aging agent A (tert-butyl hydroquinone TBHQ) is 2.0% , antiaging agent B (zinc dialkyldithiophosphate ZDDP) is 2.0% (as the biological regeneration agent component and mass percentage content of not adding antiaging agent as contrast: biological oil (epoxy vegetable oil) is 92.0% , dibutyl phthalate is 8.0%);

[0046] 2) Put the bio-oil into the reaction vessel, under constant temperature control, the temperature is about 100°C, and the shearer stirs at a low speed for 15-30 minutes, and the stirring speed is about 60r / min. While stirring, add the plasticizer collar according to the determined mass percentage Dibutyl phthalate, initially produced biological regeneration agent;

[0047] 3) Put the biological regeneration agent prepared ...

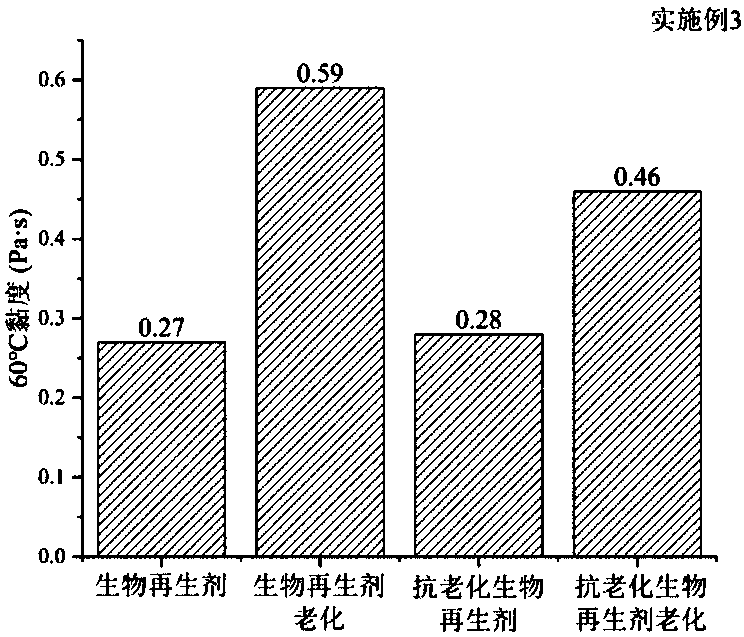

Embodiment 3

[0059] A bio-oil-based anti-aging asphalt regenerant and a preparation method thereof, comprising the steps of:

[0060] 1) Its components and mass percent content are: bio-oil (epoxy vegetable oil) is 88.5%, dibutyl phthalate is 6.0%, anti-aging agent A (tert-butyl hydroquinone TBHQ) is 4.0% , antiaging agent B (zinc dialkyldithiophosphate ZDDP) is 1.5% (as the biological regeneration agent component and mass percentage content of not adding antiaging agent as contrast: biological oil (epoxy vegetable oil) is 94.0% , dibutyl phthalate is 6.0%);

[0061] 2) Put the bio-oil into the reaction vessel, under constant temperature control, the temperature is about 100°C, and the shearer stirs at a low speed for 15-30 minutes, and the stirring speed is about 60r / min. While stirring, add the plasticizer collar according to the determined mass percentage Dibutyl phthalate, initially produced biological regeneration agent;

[0062] 3) Put the biological regeneration agent prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com