Preparation method of CeO2-ZrO2-Al2O3 oxygen-storage material

A technology of ceo2-zro2-al2o3 and oxygen storage materials, which is applied in the field of microwave calcination co-precipitation preparation, can solve the problems of incomplete cerium-zirconium complexes, uneven particle mixing, and insufficient uniformity, and achieve easy automatic control and thermal stability Good, high heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

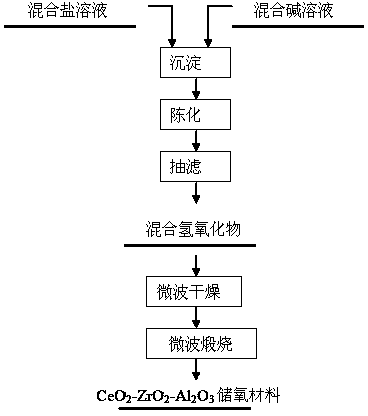

Method used

Image

Examples

Embodiment 1

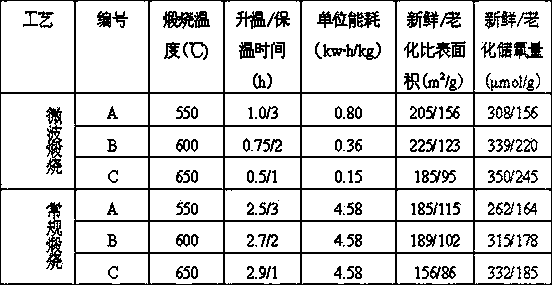

[0029] Firstly, 25%Ce(NO 3 ) 3 ·6H 2 O, 25%Zr(NO 3 ) 4 ·8H 2 O and 50%Al(NO 3 ) 3 ·6H 2 O was added to deionized water to prepare a mixed salt solution, and 2% H 2 o 2 Will Ce 3+ Oxidized to Ce 4+ , the solution changed from colorless to light yellow, then added 5% PVA, and stirred for 30min. Then mix ammonium carbonate and ammonia water according to the mass ratio of 1:1 to prepare a buffered alkali solution for later use. The mixed salt solution and the prepared buffered alkali solution are mixed by co-current method and continuously stirred, and the pH of the solution is controlled to be 8. After the purplish red precipitation is complete, it is aged at 85°C for 8h. The aged solution was vacuum filtered to obtain CeO 2 -ZrO 2 -Al 2 o 3 Oxygen storage material precursor filter cake A. The obtained CeO 2 -ZrO 2 -Al 2 o 3 Oxygen storage material precursor filter cake is dried in a 2.45GHz frequency industrial microwave oven with a microwave heating power ...

Embodiment 2

[0031] Firstly, 25%Ce(NO 3 ) 3 ·6H 2 O, 25%Zr(NO 3 ) 4 ·8H 2 O and 50%Al(NO 3 ) 3 ·6H 2 O was added to deionized water to prepare a mixed salt solution, and 3% H 2 o 2 Will Ce 3+ Oxidized to Ce 4+ , the solution changed from colorless to light yellow, then added 7.5% PVA, and stirred for 45min. Then, ammonium carbonate and ammonia water are formulated into a buffered alkali solution according to the mass ratio of 3:2 for later use. The mixed salt solution and the prepared buffered alkali solution are mixed in parallel and continuously stirred to control the pH of the solution to 9. After the purplish red precipitation is complete, it is aged at 90°C for 6h. The aged solution was vacuum filtered and spray-dried to obtain CeO 2 -ZrO 2 -Al 2 o 3 Oxygen storage material precursor powder B. The obtained CeO 2 -ZrO 2 -Al 2 o 3 Oxygen storage material precursor filter cake is dried in a 2.45GHz frequency industrial microwave oven with a microwave heating power o...

Embodiment 3

[0033] Firstly, 25%Ce(NO 3 ) 3 ·6H 2 O, 25%Zr(NO 3 ) 4 ·8H 2 O and 50%Al(NO 3 ) 3 ·6H 2 O was added to deionized water to prepare a mixed salt solution, and 5% H 2 o 2 Will Ce 3+ Oxidized to Ce 4+ , the solution changed from colorless to light yellow, then added 10% PVA, and stirred for 60min. Then, ammonium carbonate and ammonia water are formulated into a buffered alkali solution according to the mass ratio of 4:3 for later use. The mixed salt solution and the prepared buffered alkali solution are mixed by co-current method and continuously stirred, and the pH of the solution is controlled to be 10. After the purplish red precipitation is complete, it is aged at 95°C for 4h. The aged solution was vacuum filtered and spray-dried to obtain CeO 2 -ZrO 2 -Al 2 o 3 Oxygen storage material precursor powder C. The obtained CeO 2 -ZrO 2 -Al 2 o 3 Oxygen storage material precursor filter cake is dried in a 2.45GHz frequency industrial microwave oven with a micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com