Composition for manufacturing compound rubber mat and preparation method of composition

A technology for compounding rubber and composition, applied in the field of rubber products, can solve the problems of slow reaction speed of natural rubber, easy to be eroded by mold, incomplete reaction, etc., and achieve the effects of reducing preparation cost, low price and lowering production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

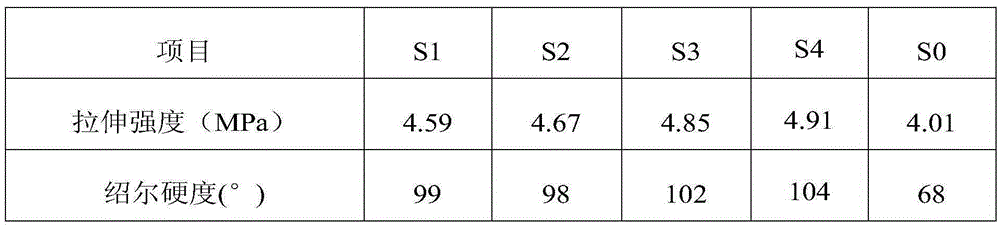

Embodiment 1

[0049] Composition for manufacturing composite rubber mat

[0050] Raw material and parts by weight array become:

[0051] Epoxidized natural rubber is 50 parts, EPDM rubber is 15 parts, nitrile rubber is 5 parts, styrene-butadiene rubber is 2 parts, butadiene rubber is 6 parts, high-styrene rubber is 8 parts, nano-zinc oxide is 1 part, 4 parts of sodium stearate, 1 part of carbon black, 1 part of antifungal agent, 2 parts of sulfur, 4 parts of PBS polymer, 2 parts of hydroxyl polyphosphate, 2 parts of sodium bisulfite parts, silane coupling agent is 4 parts.

[0052] Prepared by the following method, comprising the following steps:

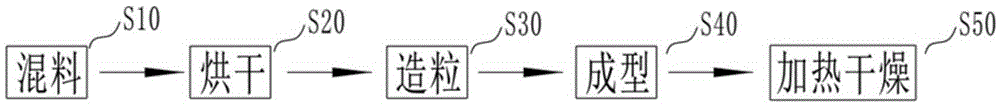

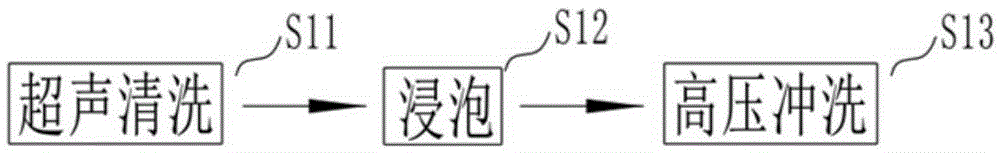

[0053] Step S10, uniformly mixing the epoxidized natural rubber, EPDM rubber, nitrile rubber, styrene-butadiene rubber, butadiene rubber, high styrene rubber, and PBS polymer in parts by weight, and putting the mixture into an ultrasonic cleaning device, Perform ultrasonic cleaning for 0.5 h at a power of 1000W and a temperature of 28°C, where...

Embodiment 2

[0059] Composition for manufacturing composite rubber mat

[0060] Raw material and parts by weight array become:

[0061] Epoxidized natural rubber is 80 parts, EPDM rubber is 30 parts, nitrile rubber is 15 parts, styrene-butadiene rubber is 5 parts, butadiene rubber is 12 parts, high-styrene rubber is 20 parts, nano-zinc oxide is 6 parts, sodium stearate is 6 parts, carbon black is 3 parts, fungicide is 6 parts, sulfur is 8 parts, PBS polymer is 10 parts, hydroxyl polyphosphate is 5 parts, sodium bisulfite is 5 parts parts, silane coupling agent is 8 parts.

[0062] Prepared by the following method, comprising the following steps:

[0063] Step S10, uniformly mixing the epoxidized natural rubber, EPDM rubber, nitrile rubber, styrene-butadiene rubber, butadiene rubber, high styrene rubber, and PBS polymer in parts by weight, and putting the mixture into an ultrasonic cleaning device, Perform ultrasonic cleaning for 2 hours at a power of 3000W and a temperature of 38°C, whe...

Embodiment 3

[0069] Composition for manufacturing composite rubber mat

[0070] Raw material and parts by weight array become:

[0071] Epoxidized natural rubber is 65 parts, EPDM rubber is 23 parts, nitrile rubber is 10 parts, styrene-butadiene rubber is 3.5 parts, butadiene rubber is 9 parts, high-styrene rubber is 14 parts, nano-zinc oxide is 3.5 parts, sodium stearate is 5 parts, carbon black is 2 parts, fungicide is 3.5 parts, sulfur is 5 parts, PBS polymer is 7 parts, hydroxyl polyphosphate is 3.5 parts, sodium bisulfite is 3.5 parts parts, silane coupling agent is 6 parts.

[0072] Prepared by the following method, comprising the following steps:

[0073] Step S10, uniformly mixing the epoxidized natural rubber, EPDM rubber, nitrile rubber, styrene-butadiene rubber, butadiene rubber, high styrene rubber, and PBS polymer in parts by weight, and putting the mixture into an ultrasonic cleaning device, Ultrasonic cleaning was performed for 1.25 hours at a power of 2000W and a tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com