Spun-dyed parallel composite elastic fiber

A technology of composite elastic fiber and pre-spinning coloring, which is applied in the direction of adding pigments to the spinning solution and conjugating synthetic polymer artificial filaments, etc., which can solve the problems of increased fineness unevenness, high processing costs, and labor-intensive and time-consuming processing. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

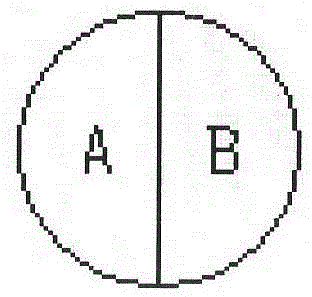

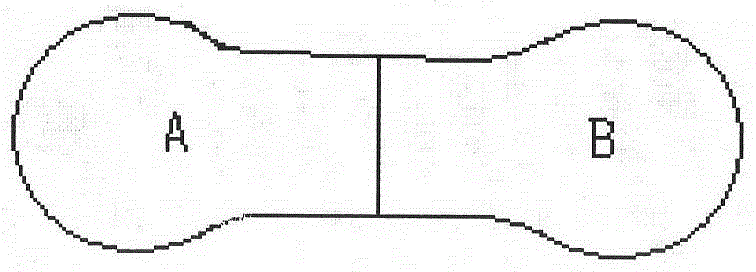

[0020] A kind of colored side-by-side composite elastic fiber before spinning has a side-by-side composite structure, the side-by-side composite elastic fiber has two components A and B, the A component is PTT, the B component is PET, A component:B component=40: 60 (mass ratio).

[0021] Color masterbatch: The color masterbatch in component A and B is composed of colorants, organic pigments with high light fastness and ester-soluble pigments with a particle size of less than 150nm, and the content of colorants in the color masterbatches is 35wt%, the color masterbatch used in the two components of A and B, the colorant formula is the same but the rheology of the carrier is different, and the melting point of the carrier is different.

[0022] PTT component: the carrier melting point of the masterbatch is 228°C, and the amount of the masterbatch is 3.0wt%;

[0023] PET component: The carrier melting point of the color masterbatch is 252°C, and the amount of the color masterbat...

Embodiment 2

[0029] A kind of colored side-by-side composite elastic fiber before spinning has a side-by-side composite structure, and the side-by-side composite elastic fiber has two components A and B, the A component is PTT, the B component is PET, A component:B component=30: 70 (mass ratio).

[0030] Color masterbatch: The color masterbatch in component A and B is composed of colorants, organic pigments with high light fastness and ester-soluble pigments with a particle size of less than 150nm, and the content of colorants in the color masterbatches is 30wt%, the color masterbatch used in the two components of A and B has the same colorant formula, but the rheology of the carrier is different, and the melting point of the carrier is different.

[0031] PTT component: the melting point of the carrier of the masterbatch is 228°C, and the amount of the masterbatch is 2.5wt%;

[0032] PET component: The carrier melting point of the color masterbatch is 252°C, and the amount of the color m...

Embodiment 3

[0037] A kind of colored side-by-side composite elastic fiber before spinning, has a side-by-side composite structure, the side-by-side composite elastic fiber has two components A and B, A component is PTT, B component is PET, A component:B component=50: 50 (mass ratio).

[0038] Color masterbatch: The color masterbatch in component A and B is composed of colorants, organic pigments with high light fastness and ester-soluble pigments with a particle size of less than 150nm, and the content of colorants in the color masterbatches is 40wt%, the color masterbatch used in the two components of A and B has the same colorant formula but the rheology of the carrier is different, and the melting point of the carrier is different.

[0039] PTT component: the carrier melting point of the masterbatch is 228°C, and the amount of the masterbatch is 2.0wt%;

[0040]PET component: the carrier melting point of the color masterbatch is 252°C, and the amount of the color masterbatch is 2.0wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com