A acidic dye dyeing accuracy improvement agent and its application

A fastness-improving, acid dye technology, used in dyeing, textiles and papermaking, etc., can solve the problems of washing resistance, non-hard hand feeling, poor light fastness, etc., and achieve high affinity and good light fastness. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

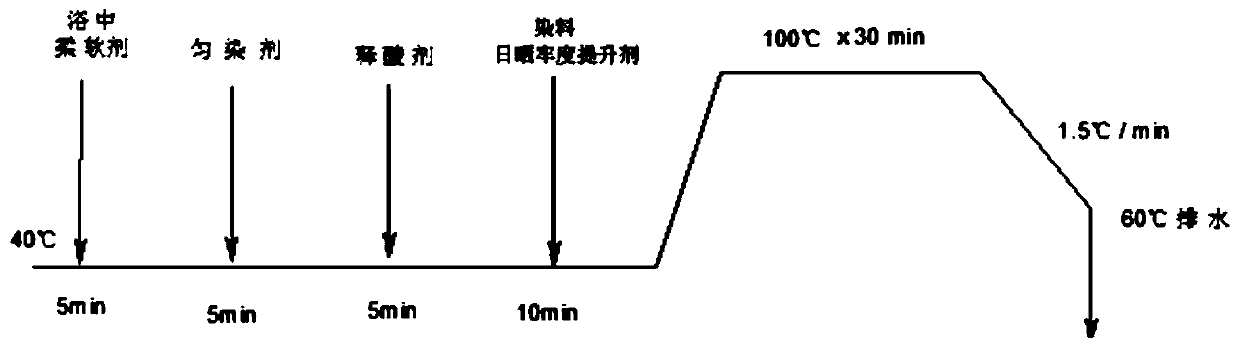

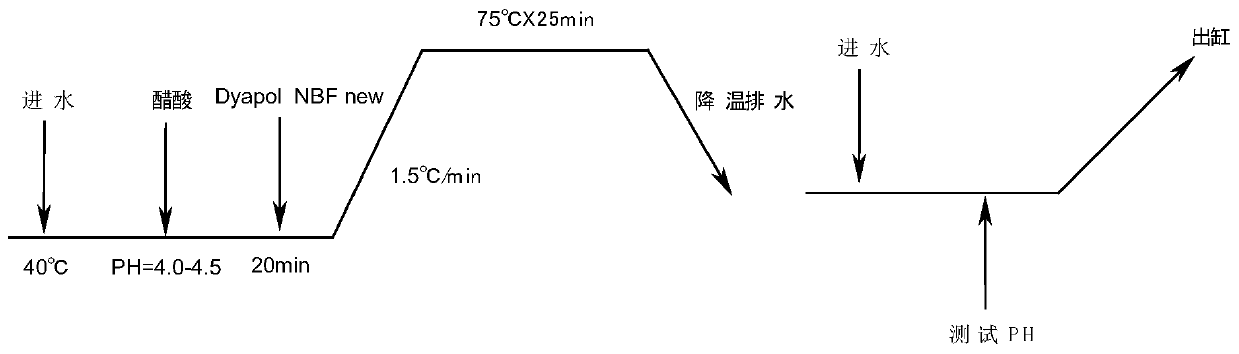

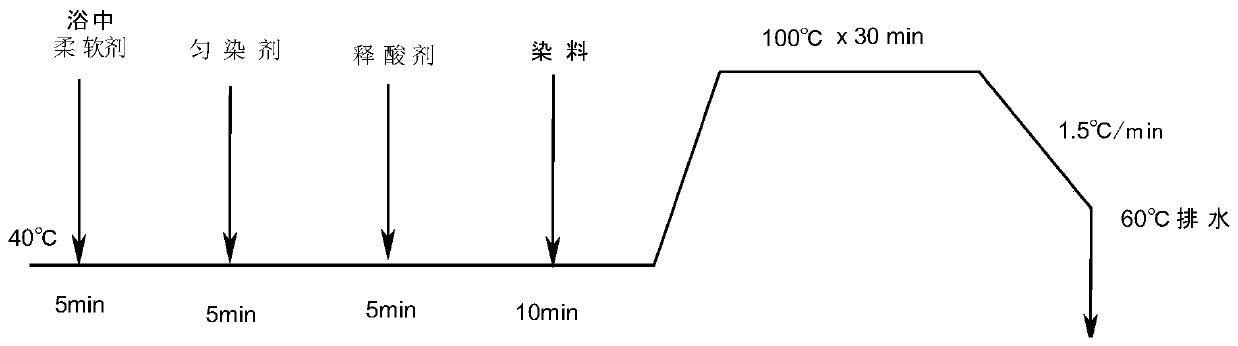

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: (product A)

[0035] The mass percent of each component of the acid dye light fastness improving agent of the present embodiment is:

[0036]

[0037] Butylmethoxydibenzoylmethane, 3-[3-(2H-benzotriazol-2-yl)-4-hydroxy-5-tert-butylphenyl]-propionic acid-polyethylene glycol 300 ester and tetrakis (2,2,6,6-tetramethyl-4-piperidinyl) 1,2,3,4-butane tetracarboxylate were added to the reaction kettle, stirred for 20min to mix evenly, slowly added ten Stir isopropyl tetra-acid for 30 minutes, stir evenly, add oleic acid and oleic acid polyoxyethylene (EO~18) ether and stir for 45-60 minutes, then heat up to 60-65°C, all reactants dissolve and become transparent liquid, gradually Add water, stir at high speed for 45-60min, cool down, the reaction product is a milky white emulsion, stand still for a week, no precipitation and floating matter appear.

Embodiment 2

[0038] Embodiment 2: (product B)

[0039]

[0040] Butylmethoxydibenzoylmethane, 3-[3-(2H-benzotriazol-2-yl)-4-hydroxy-5-tert-butylphenyl]-propionic acid-polyethylene glycol 300 ester Add tetrakis(2,2,6,6-tetramethyl-4-piperidinyl) 1,2,3,4-butane tetracarboxylate into the reaction kettle respectively, stir for 20 minutes to mix evenly, slowly add Stir isopropyl myristate for 30 minutes, stir evenly, add oleic acid (lubricant) and oleic acid polyoxyethylene (EO-18) ether (emulsifier) and stir for 45-60 minutes, then heat up to 60-65°C, react All the substances were dissolved and turned into a transparent liquid. Gradually add water, stir at high speed for 45-60min, cool down, the reaction product is a milky white emulsion, stand still for a week, no precipitation and floating matter appear.

Embodiment 3

[0041] Embodiment 3: (product C)

[0042]

[0043]

[0044] Butylmethoxydibenzoylmethane, 3-[3-(2H-benzotriazol-2-yl)-4-hydroxy-5-tert-butylphenyl]-propionic acid-polyethylene glycol 300 ester Add tetrakis(2,2,6,6-tetramethyl-4-piperidinyl) 1,2,3,4-butane tetracarboxylate into the reaction kettle respectively, stir for 20 minutes to mix evenly, slowly add Stir isopropyl myristate for 30 minutes, stir evenly, add oleic acid (lubricant) and oleic acid polyoxyethylene (EO-18) ether (emulsifier) and stir for 45-60 minutes, then heat up to 60-65°C, react All the substances were dissolved and turned into a transparent liquid. Gradually add water, stir at high speed for 45-60min, cool down, the reaction product is a milky white emulsion, stand still for a week, no precipitation and floating matter appear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com