Patents

Literature

36 results about "Sheep shearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sheep shearing is the process by which the woollen fleece of a sheep is cut off. The person who removes the sheep's wool is called a shearer.Typically each adult sheep is shorn once each year (a sheep may be said to have been "shorn" or "sheared", depending upon dialect).

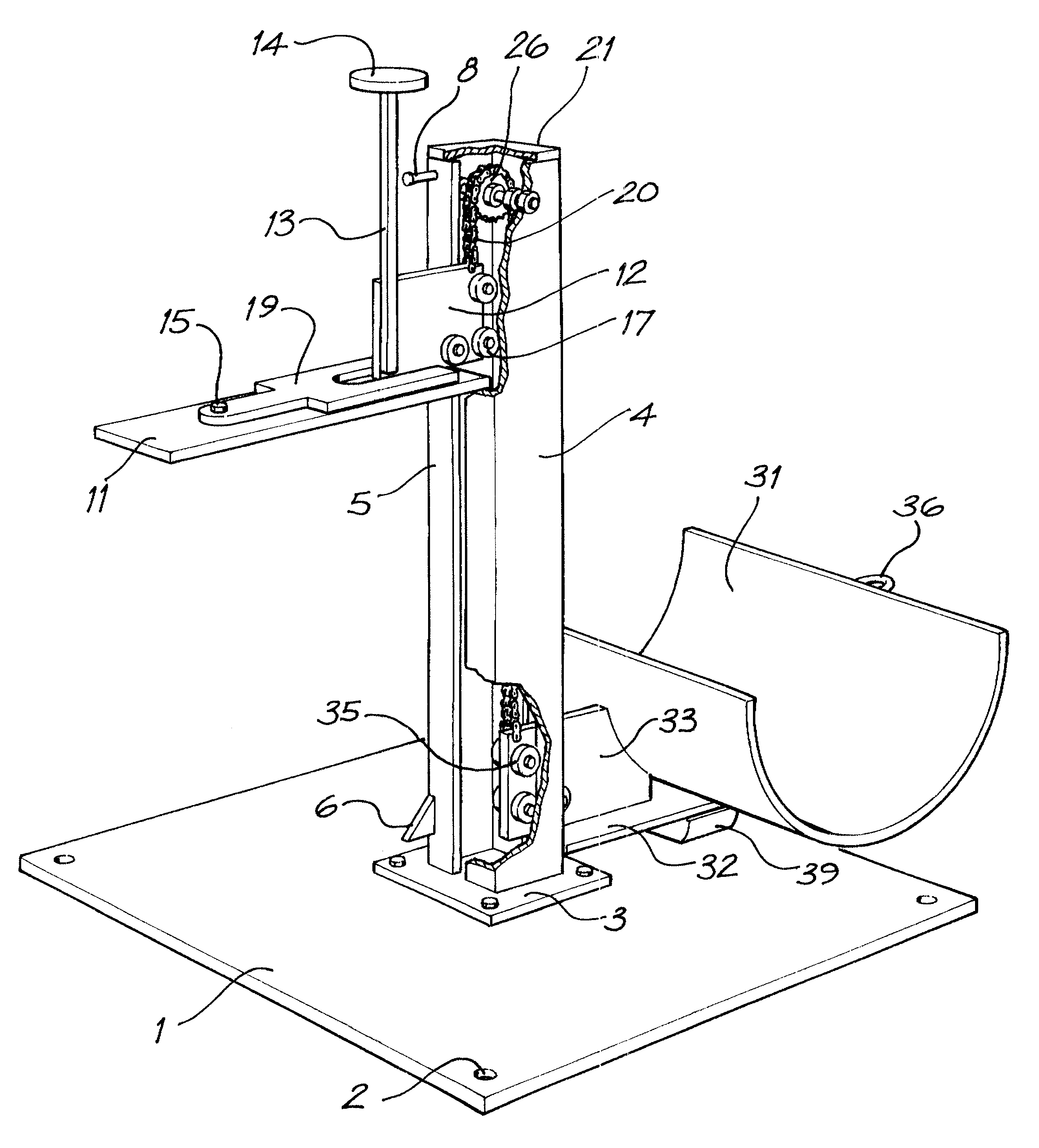

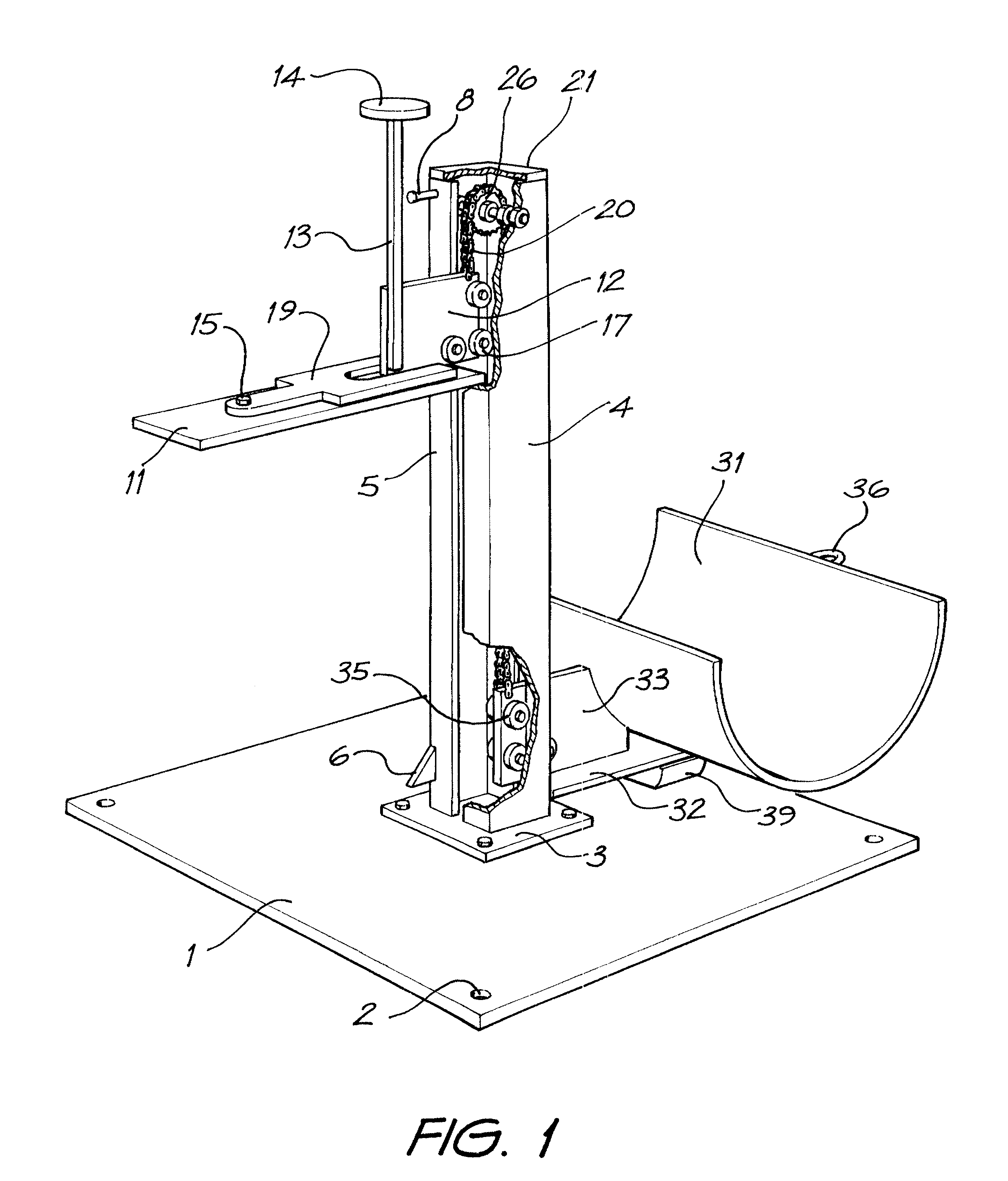

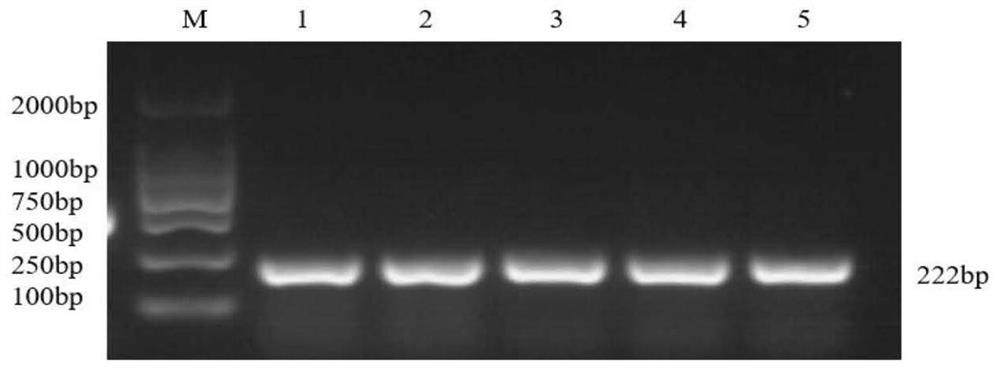

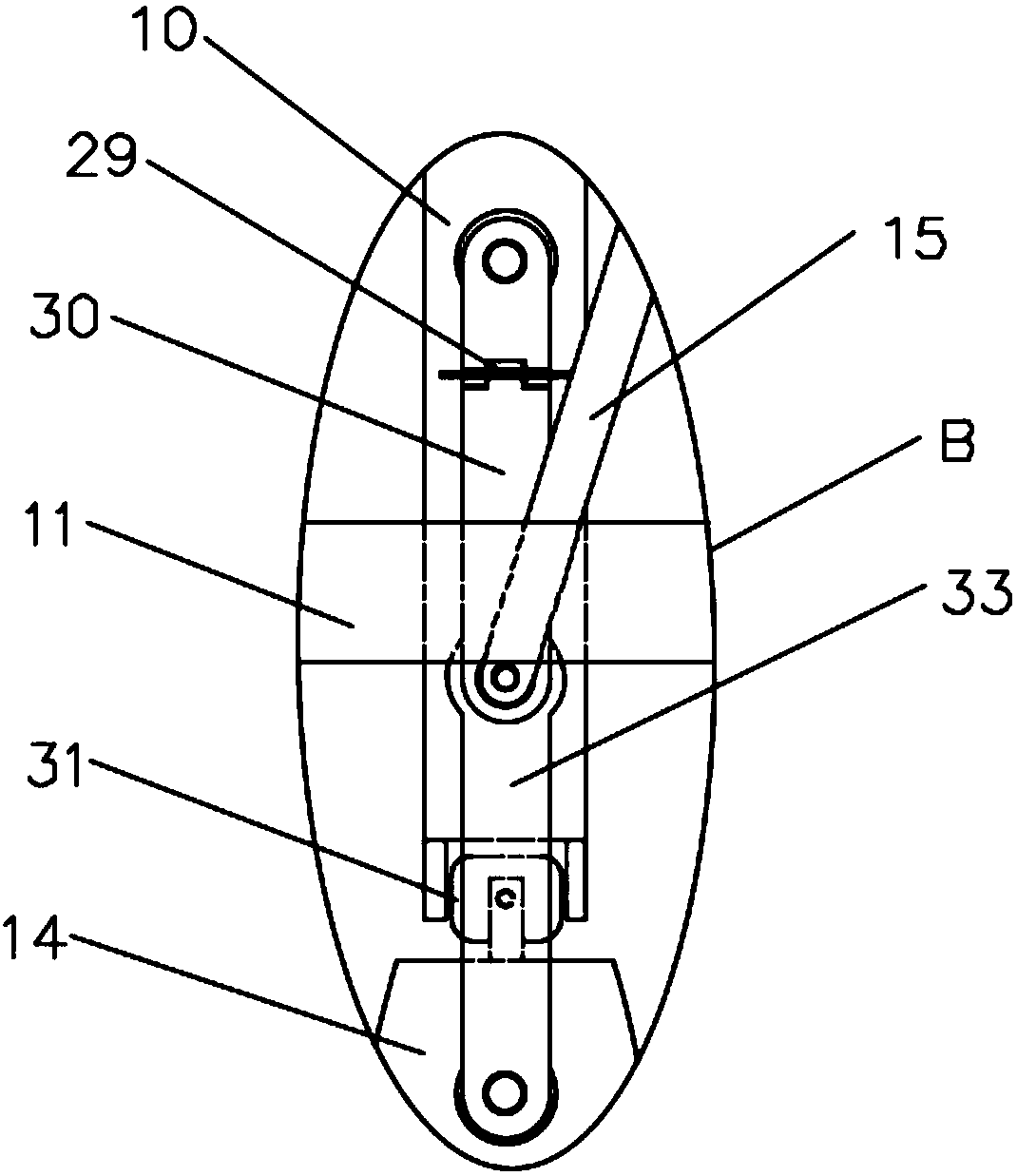

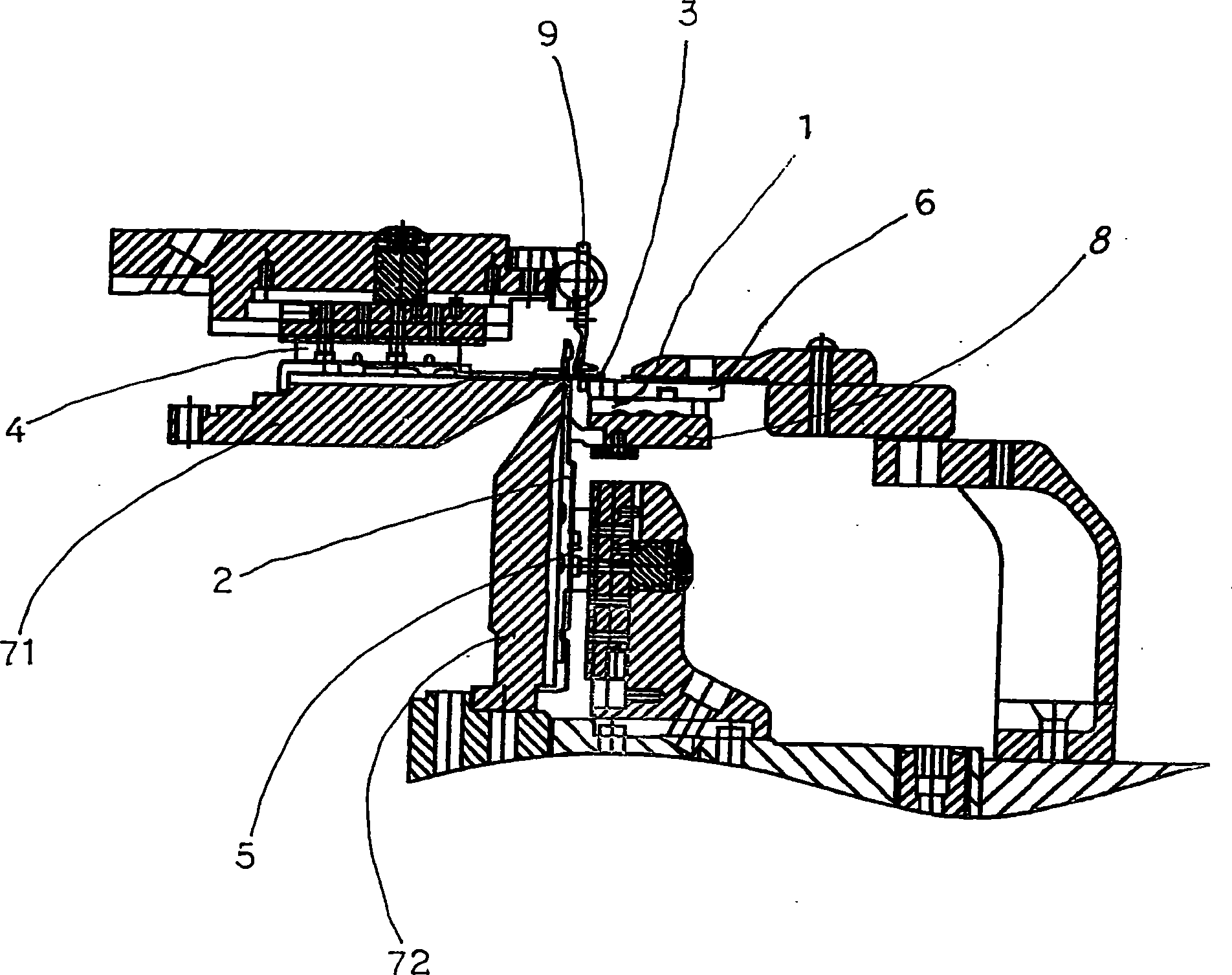

Shearing lifting jack

InactiveUS6477986B1Improve toleranceSimple working processAnimal housingOther apparatusJackscrewEngineering

Shearing lifting jack for shearing sheep comprises a cradle (31) for holding a sheep on its back or stomach and which is shaped so as to allow the sheep to be rolled from its back to its stomach or vice versa during the shearing operation. Lifting means for example in the form of a rolling chain (20) is provided to move the cradle from a first loading / unloading position adjacent the floor of a shearing shed or other suitable location for shearing sheep and a second raised position for shearing the sheep approximating the height of a work bench. This allows the sheep to be lifted whilst it is shorn in order that the sheerer avoids bending over the sheep. The lifting means is operable between the first loading / unloading position and second shearing position by a single unassisted shearer.

Owner:KORJENIC HAMID

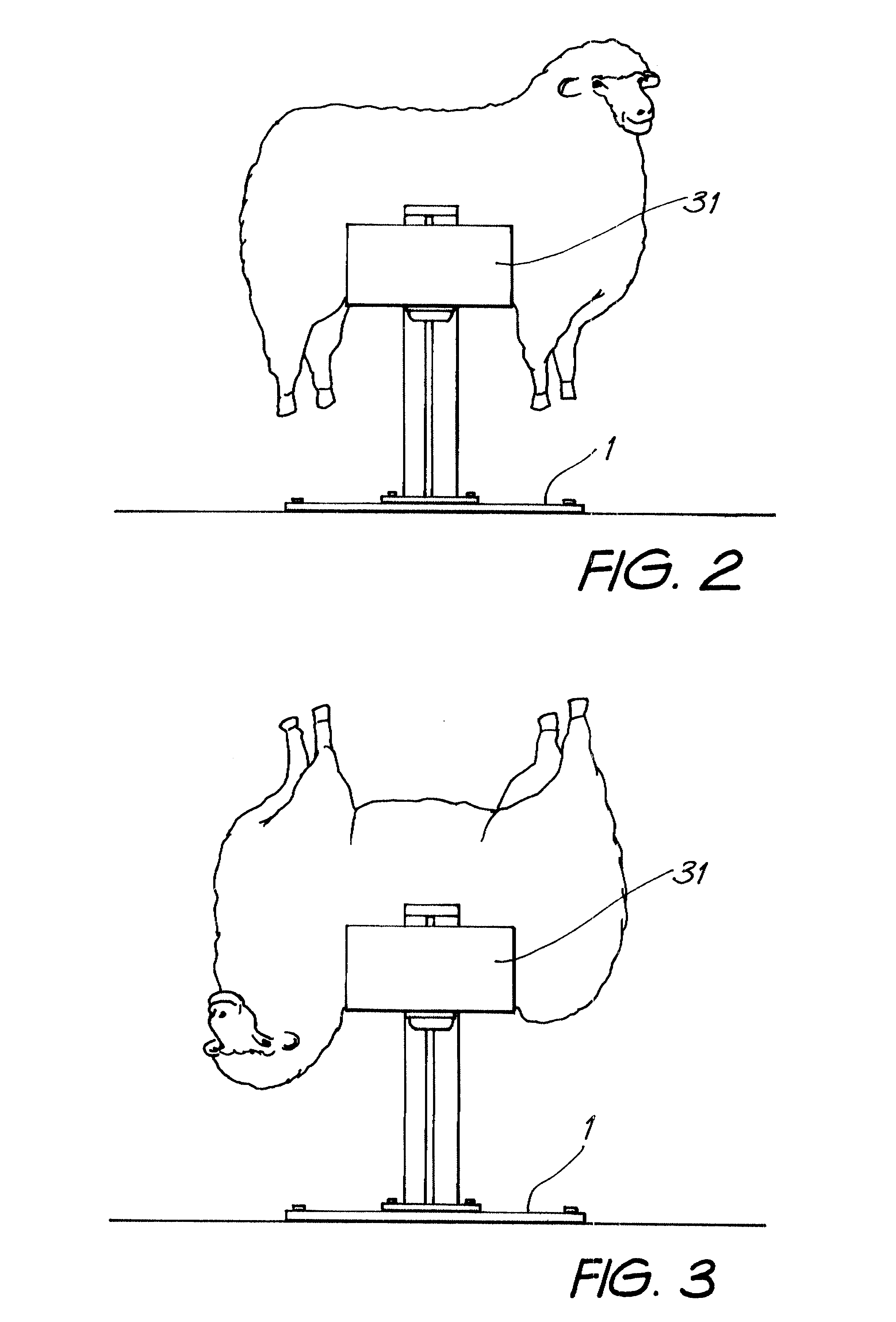

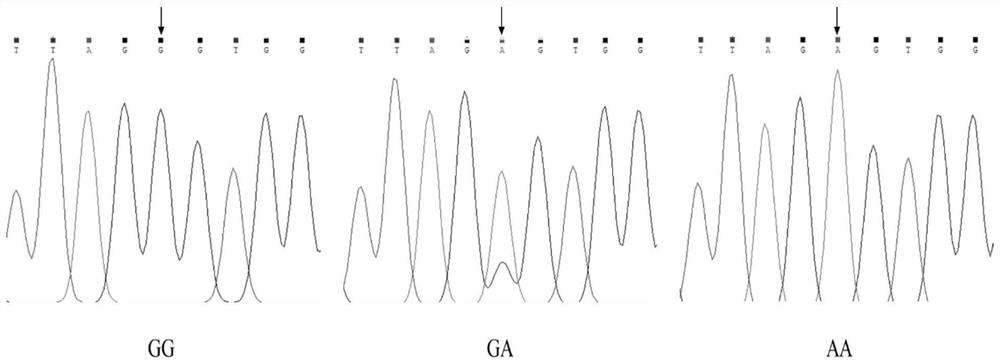

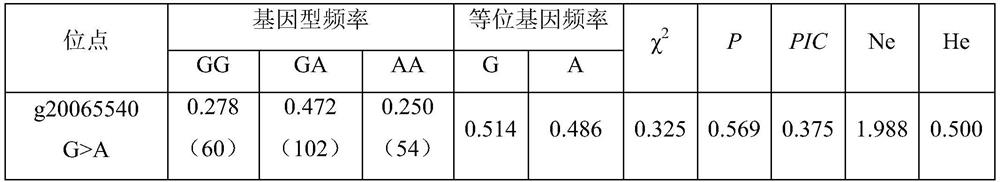

SNP (Single Nucleotide Polymorphism) molecular marker capable of influencing wool shearing amount of alpine merino and application of SNP molecular marker

ActiveCN114214428AImproving Breeding AccuracyImprove accuracyMicrobiological testing/measurementDNA/RNA fragmentationNucleotideMolecular genetics

The invention belongs to the technical field of molecular genetics, and particularly relates to an SNP (Single Nucleotide Polymorphism) molecular marker influencing the wool shearing amount of alpine merino and application. The SNP molecular marker is located at the 20065540th nucleotide site G / A mutation on the fifth chromosome of the international sheep reference genome Oarv4.0 version. The invention further relates to a specific primer pair for detecting the SNP molecular marker by using a PCR technology, a kit containing the primer pair and a nucleotide polymorphism detection method, and compared with a traditional detection method, the technology has the advantages of high accuracy, high detection speed, low cost, easiness in result judgment and the like. SNP locus detection is used for carrying out early selection of the shearing amount of the high-mountain merino sheep, shortening the breeding period and accelerating the breeding process, a high-mountain merino sheep shearing amount early selection technology is established, the breeding time of the excellent character of the shearing amount of the high-mountain merino sheep is shortened, the breeding cost is reduced, and the application value is very high.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

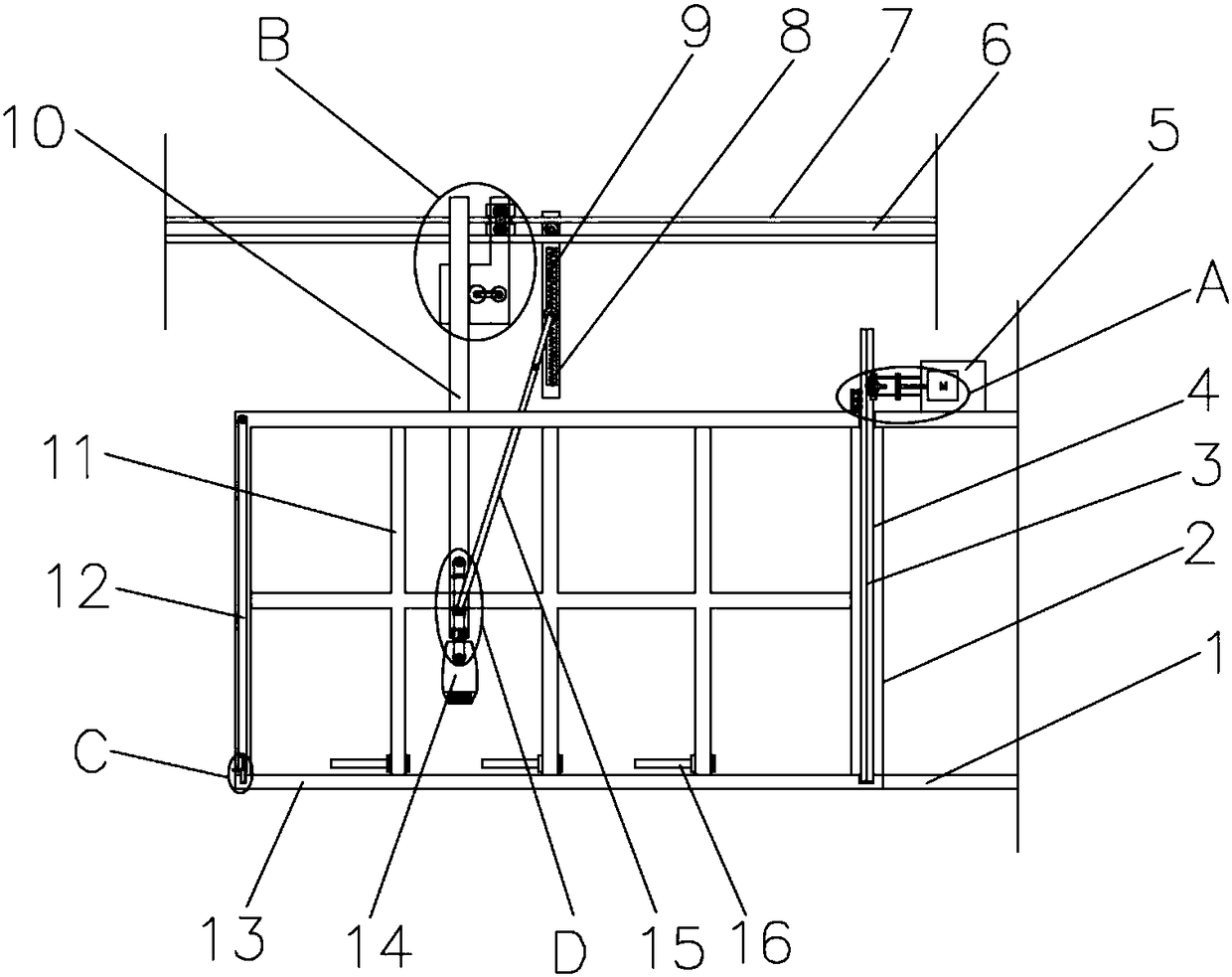

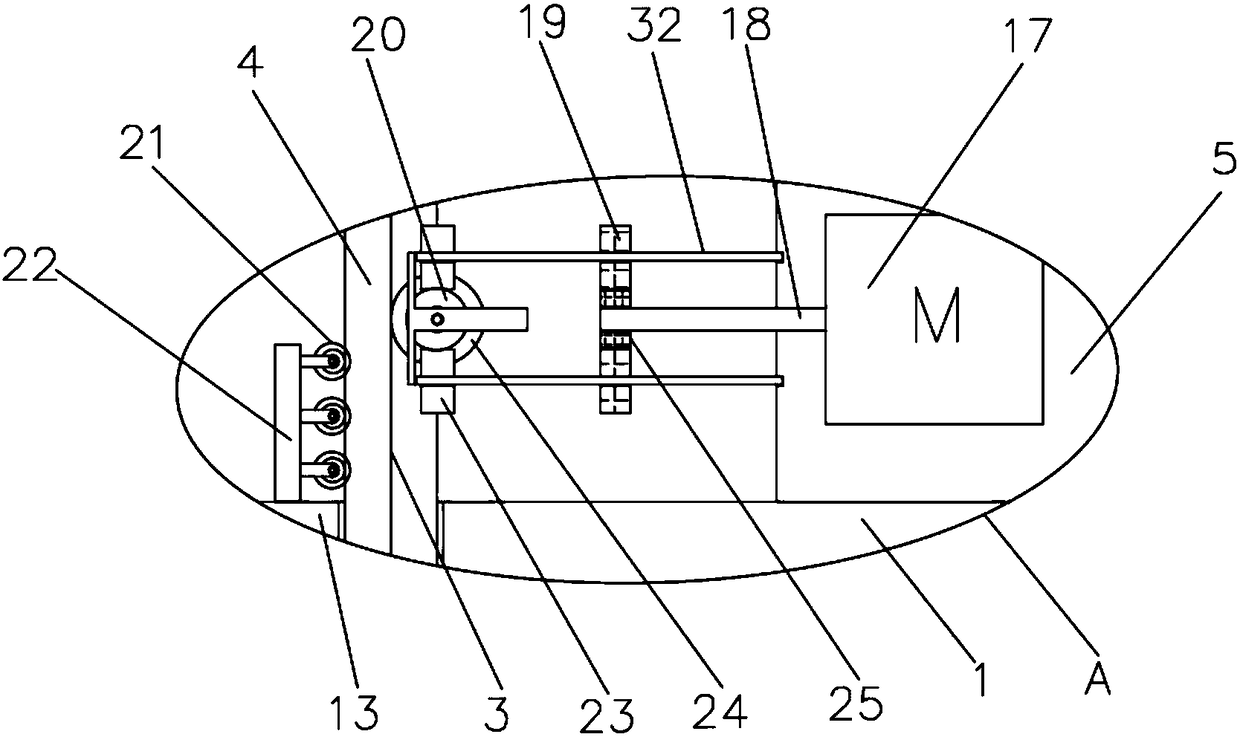

Sheep shearing device for animal husbandry

The invention discloses a sheep shearing device for animal husbandry. The sheep shearing device comprises a framework and a fence fixedly connected to the framework, a fixing frame is fixedly connected to the right side of the framework, a retaining plate is slidably and connectedly clamped in the fixing frame, the right side of the fixing frame is fixedly connected with a passage, and the upper end of the passage is fixedly connected with a motor box. A first motor is arranged in the motor box, a driving end of the first motor is rotationally connected with a lifting mechanism, a movable dooris mounted at the right end of the framework, the upper end of the movable door is fixedly connected with the framework, a clamping mechanism is mounted at the lower end of the framework, and the movable door is fixedly connected with the framework through the clamping mechanism. The sheep shearing device is simple in operation; by cooperation of the fence, a slide rail, the lifting mechanism, adriving mechanism, a connection mechanism and a moving mechanism, semi-automatic sheep shearing can be realized, an operator does not need to repeatedly bend over for operation on the whole body of sheep, and the sheep shearing device for animal husbandry is provided for users.

Owner:ANHUI PROVINCE TIANCHANG CITY ZHOUSHI SHEEP CO LTD

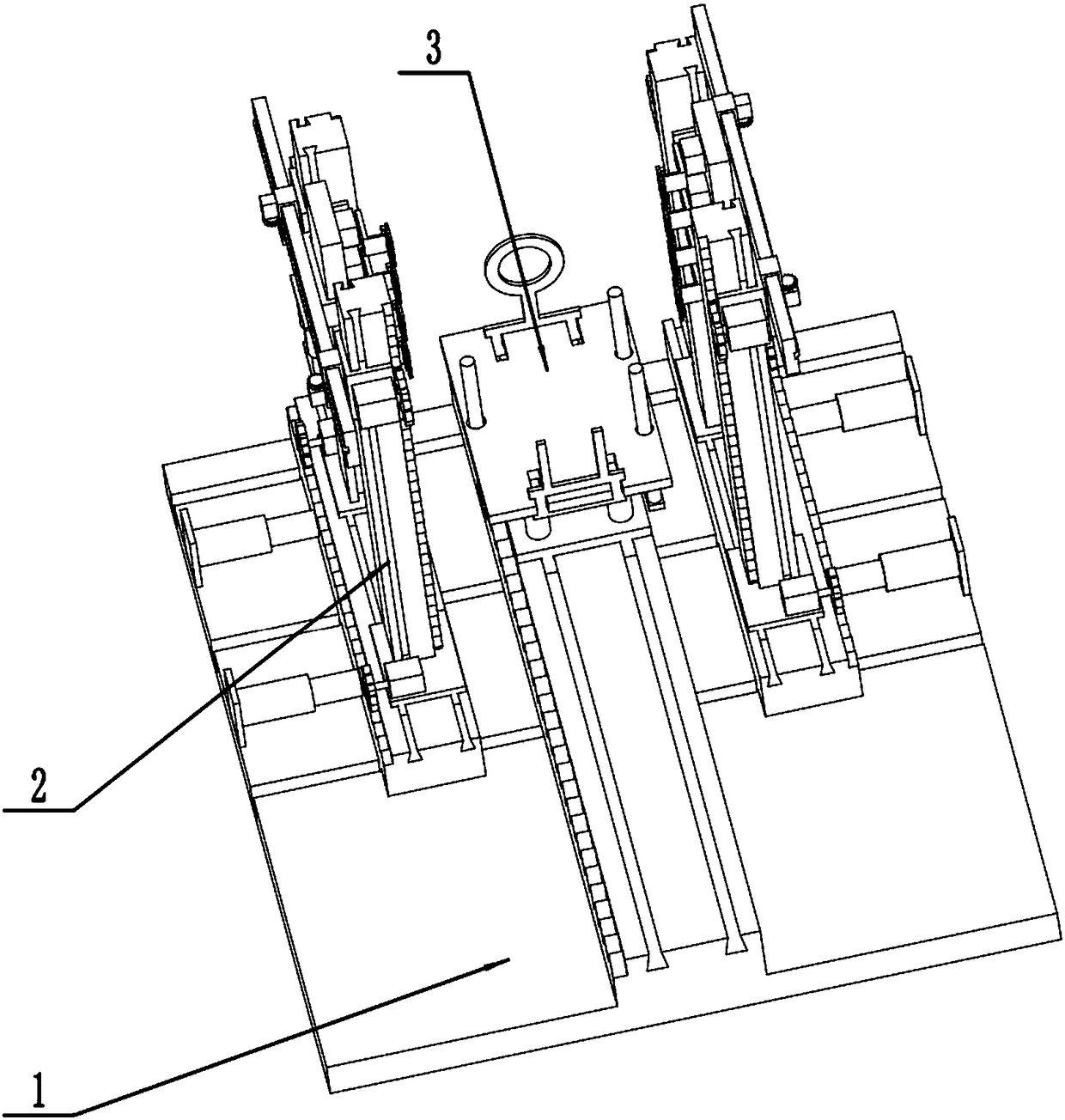

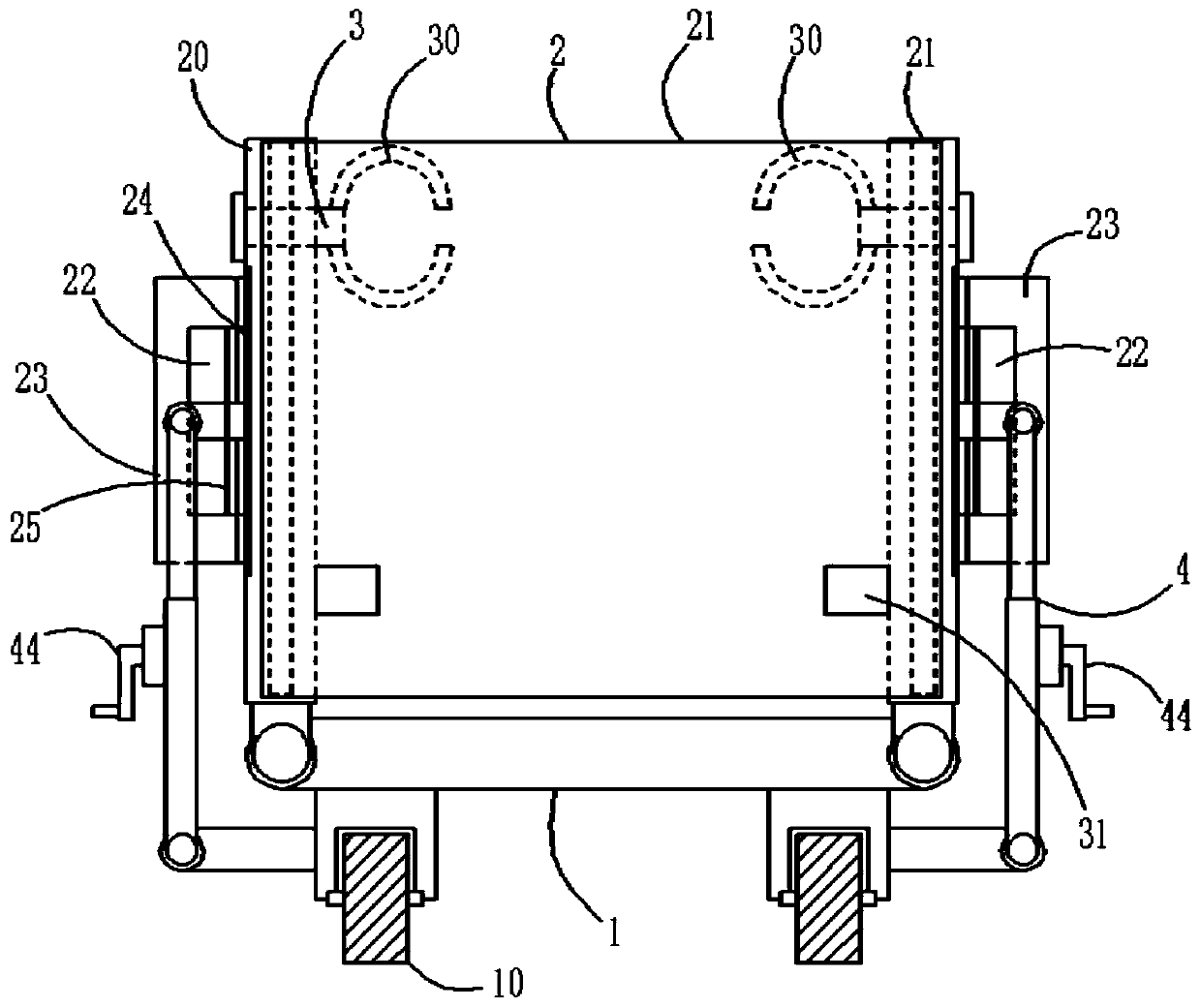

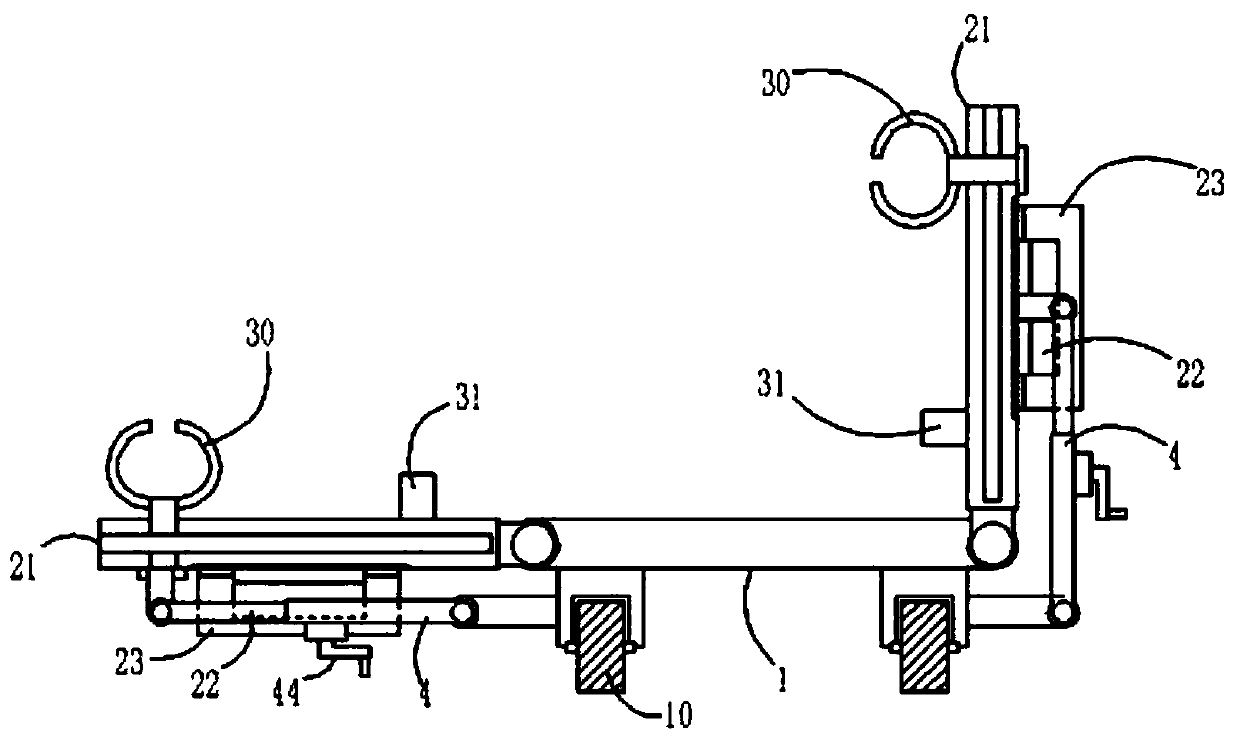

Sheep-shearing robot

ActiveCN108353814AImproved shear qualityImprove shear efficiencyOther apparatusTaming and training devicesHydraulic cylinderEngineering

A sheep-shearing robot comprises a base, two sheep shearing portions and a fixing portion. The sheep-shearing robot is characterized in that six first sliders of the two sheep shearing portions are slidably mounted in six first dovetail grooves respectively, and the outer sides of base plates of the two sheep shearing portions are fixedly connected with the ends of cylinder bodies of two groups offirst hydraulic cylinders respectively; two second sliders of the fixing portion are slidably mounted in two second dovetail grooves respectively, and a fourth gear is meshed with a first rack; a sheep needing to subjected to sheep shearing is fixed through three fixing rods, a sheep head fixing plate and a sheep back fixing plate of the fixing portion, so that the sheep cannot move disorderly, and the sheep shearing quality is improved. The sheep shearing is performed by causing eight sixth hydraulic cylinders to drive eight second blades and eight first blades for mutual cooperation, the automatic sheep shearing is achieved, and the sheep shearing efficiency is improved.

Owner:新昌县焕宏农业有限公司

Processing technology of chromium composited tan cutting broad woolskin

InactiveCN101942532ASolve the thickness problemImprove whitenessTanning treatmentPre-tanning chemical treatmentHazardous substanceHuman health

The invention provides a processing technology of chromium composited tan cutting broad woolskin, relating to the manufacturing of sheep shearing in shearling industry, in particular to the processing technology of the chromium composited tan cutting broad woolskin. The processing technology adopts specific pickling and lipase adding technology conditions, pretanning technology conditions, compound tanning technology conditions and dyeing technology conditions, thereby overcoming the defects that all physicochemical indexes of products in the prior art, such as hexavalent chromlum content, free formaldehyde content, harmful aromatic amine content and other harmful substance contents as well as color fastness index, are not effectively solved. The technology of the invention pursues beautiful appearance of products and pays attention to inherent quality and human health increasingly; and especially, three hazards contents reach departmental standards, thus the invention becomes a processing technology of sheep shearing products which is green ecological, healthy and no harmful effect on customers.

Owner:INNER MONGOLIA JIHUA SAMPLE GARMENT FUR

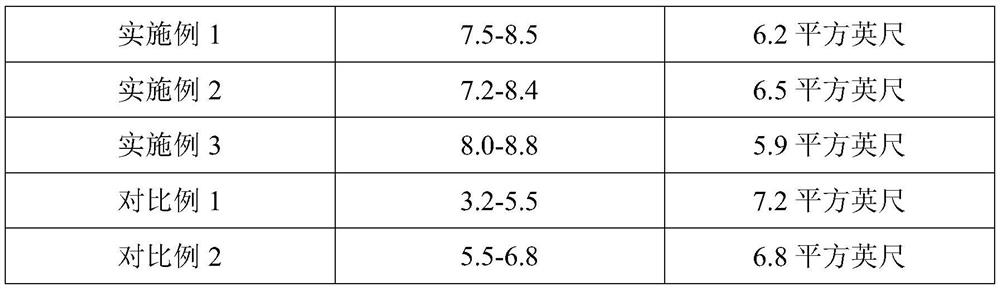

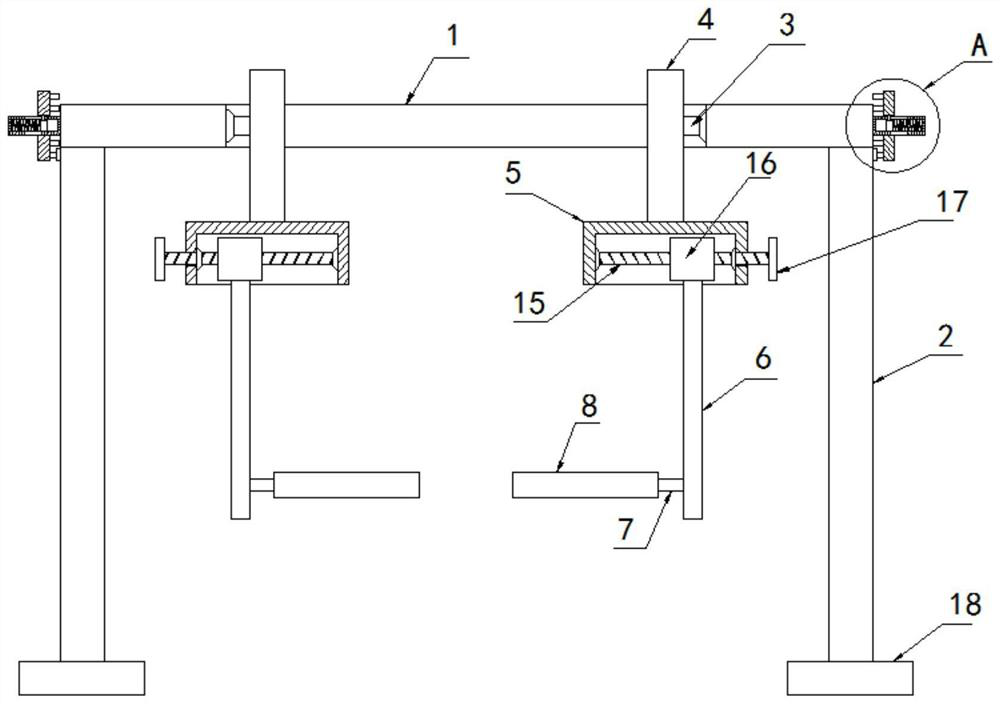

Sheep shearing auxiliary fixing device for animal husbandry

InactiveCN109845657AEasy to shearThoroughly shearedOther apparatusGrooming devicesEngineeringInverted t

The invention relates to an auxiliary fixing device for animal husbandry, in particular to a sheep shearing auxiliary fixing device for animal husbandry. According to the sheep shearing auxiliary fixing device for the animal husbandry, sheep can be fixed and conveniently sheared by people. The sheep shearing auxiliary fixing device for the animal husbandry comprises a large connecting plate, a base, left fixture blocks, a soft band, a fixing plate, a pressing plate, a triangular pressing block, a first screw rod, a small connecting plate, a small tension spring, an inverted T-shaped slider andthe like. Bases are connected to two sides of the large connecting plate in a sagittal symmetry manner in a hinged manner, and the tops of the bases are connected with the left fixture blocks. The sheep shearing auxiliary fixing device for the animal husbandry can conveniently fix legs of sheep, so that the sheep can be conveniently sheared by people, fleshes of the sheep cannot be sheared, the sheep can be conveniently turned over, and the sheep can be thoroughly sheared.

Owner:蔡伟豪

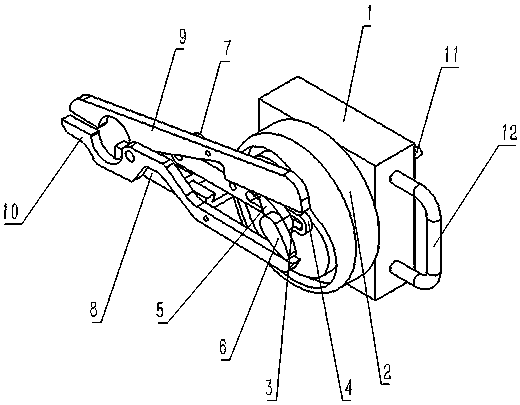

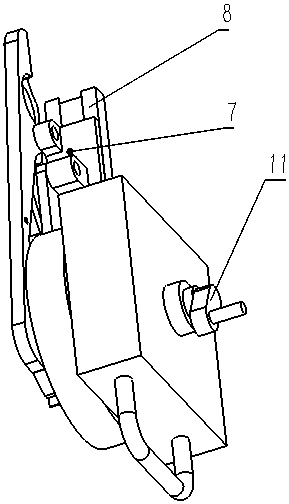

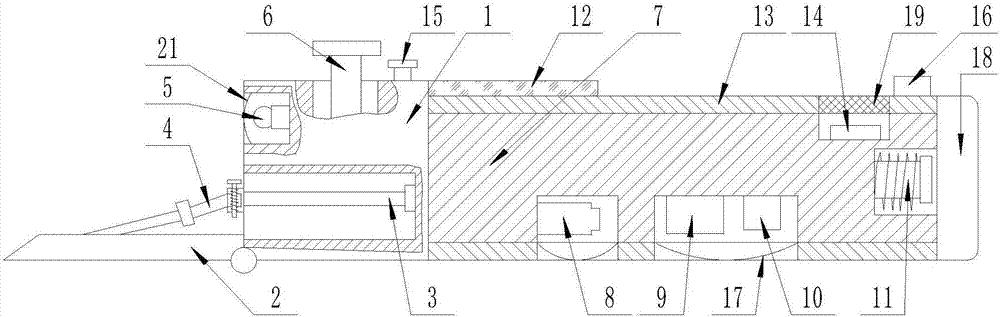

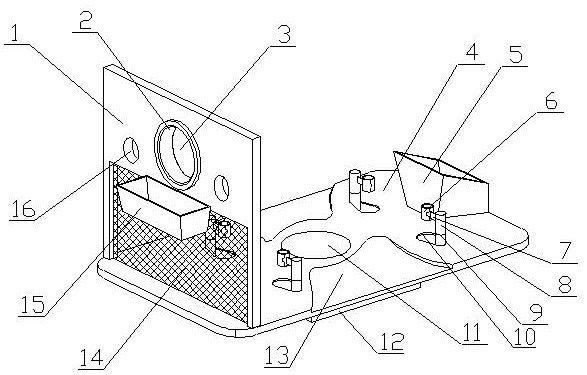

Sheep shear

The invention discloses a sheep shear. The sheep shear comprises a mounting plate. A cam disk is mounted in front of the mounting plate. A connecting shaft is arranged in the center of the cam disk ina penetrating mode. A connecting rod is arranged in front of the cam disk. The connecting shaft penetrates through the right end of the connecting rod. The front end of the connecting shaft is provided with a first rotary block. A second rotary block is arranged in front of the first rotary block. The left end of the connecting rod is connected with a sliding block. A sliding plate is arranged below the sliding block. An upper shear body is arranged in front of the sliding block. A lower shear body is arranged in front of the upper shear body. The rear end of the connecting shaft is providedwith a hand shank. A handle is arranged on the right end face of the mounting plate. In general, the sheep shear has the advantages of being good in sheep shearing effect and long in service life.

Owner:XUCHANG JIANAN DISTRICT EAST & ANIMAL HUSBANDRY PROFESSIONAL COOP

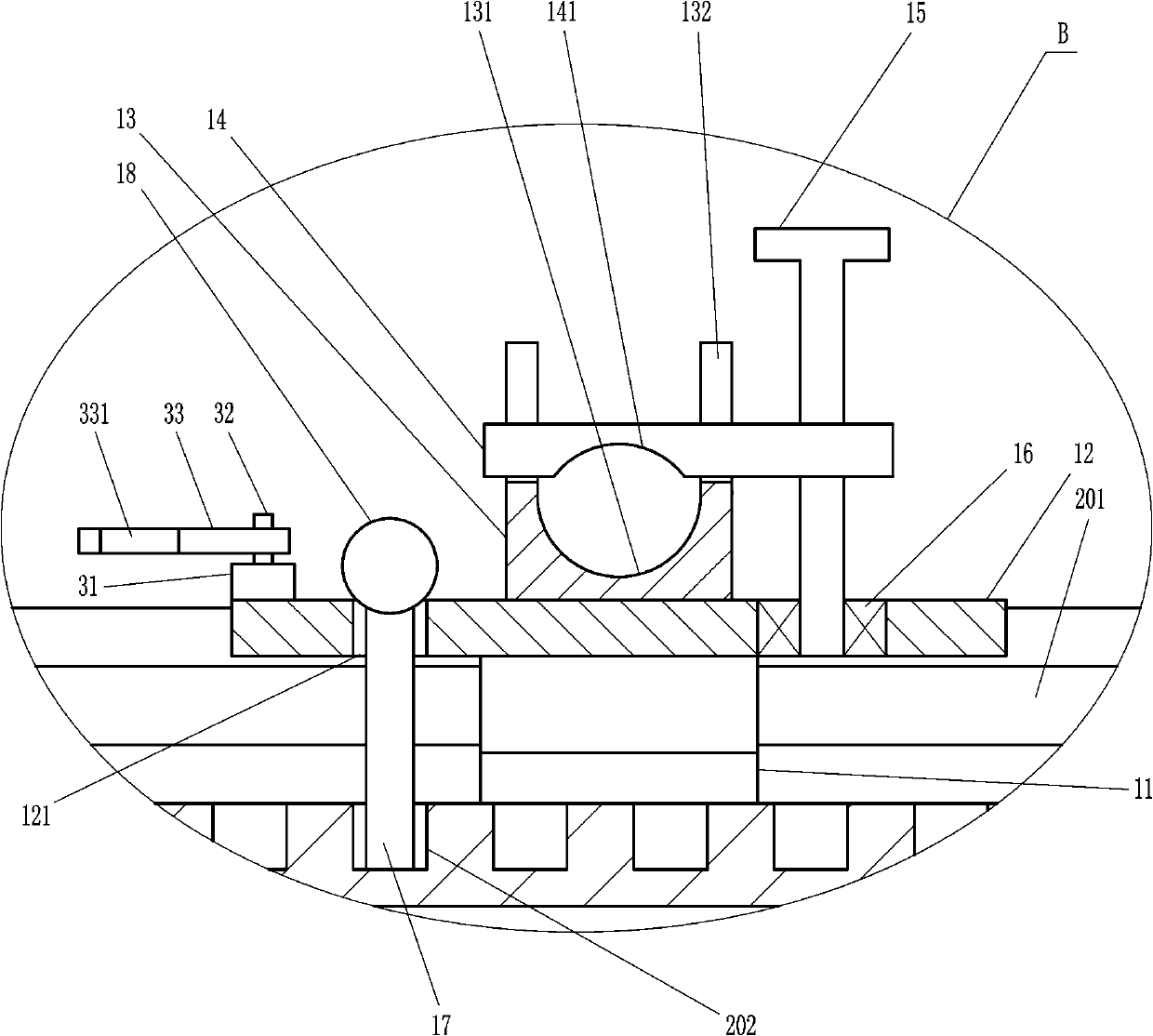

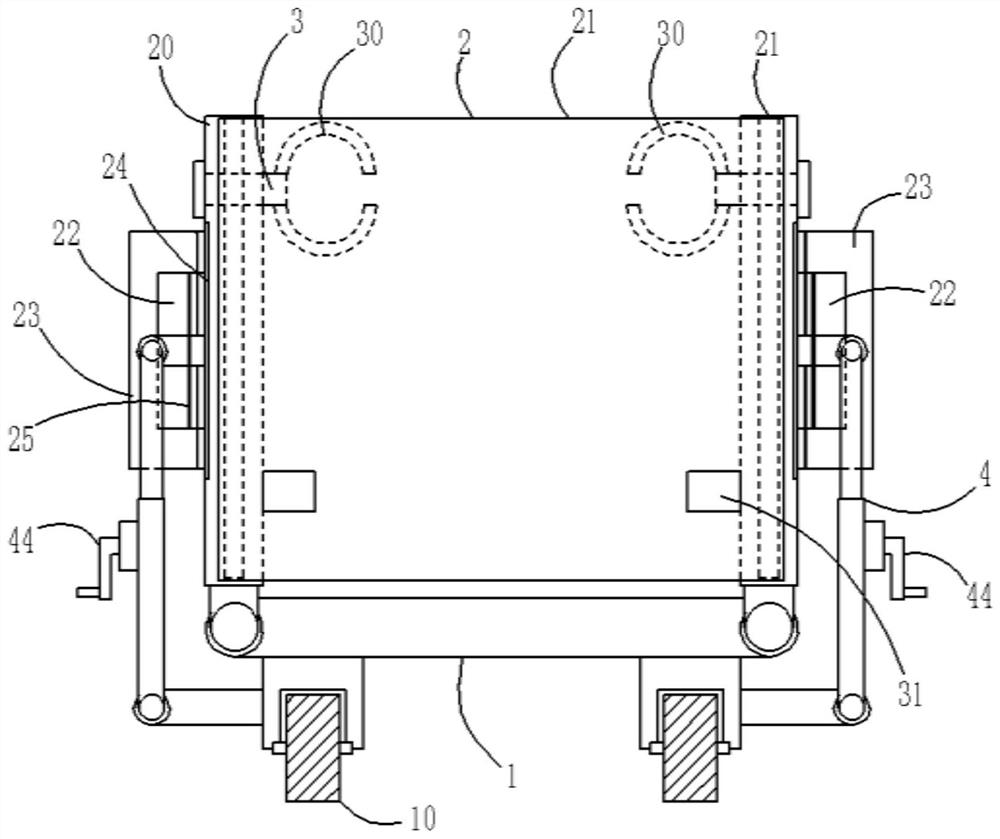

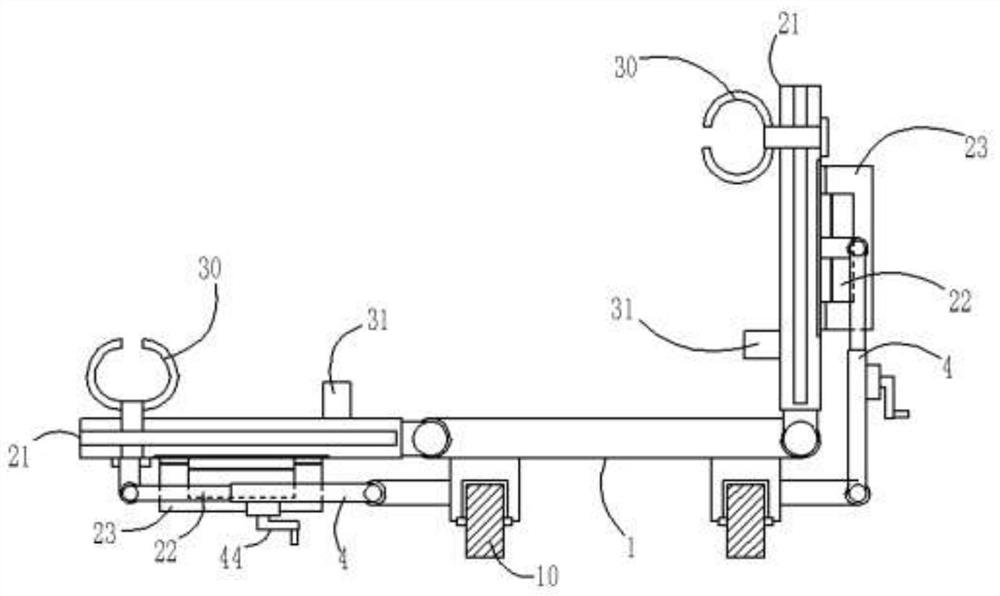

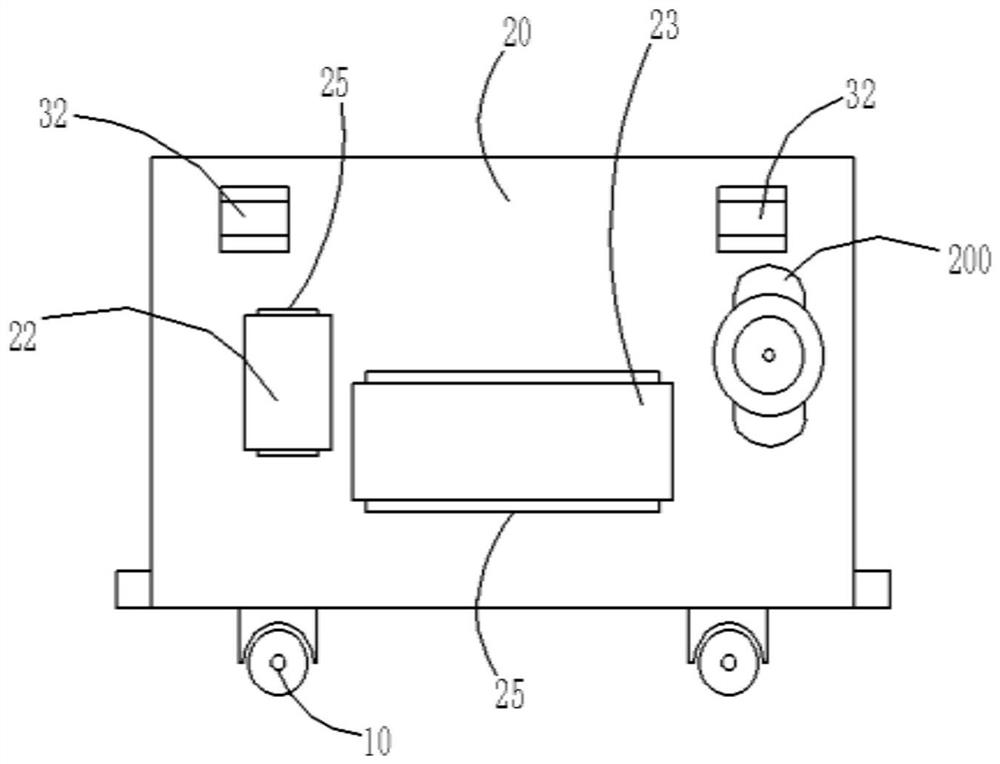

Animal husbandry breeding sheep shearing fixing device

ActiveCN109717092AImprove qualityImprove comfortOther apparatusTaming and training devicesEngineeringAnimal husbandry

The invention discloses an animal husbandry breeding sheep shearing fixing device which comprises a fixing bottom plate, a fence plate, a fixing assembly and adjusting stay rods. The fence plate comprises fixing fences and limit fences; the fixing assembly comprises neck fixing rings, sheep limb fixing seats and fixing buckles, the fixing fences are hinged onto the fixing bottom plate, sheep manure collection tanks and wool collection tanks are arranged on the fixing fences, the limit fences are clamped with the fixing fences, the neck fixing rings are arranged on the fixing fences, the limb fixing seats are arranged on the inner side surfaces of the fixing fences, the fixing buckles are arranged on the outer side surfaces of the fixing fences, and the adjusting stay rods are arranged at joints of the fixing fences and the fixing bottom plate and are used for adjusting inclination angles of the fixing fences. The animal husbandry breeding sheep shearing fixing device has the advantagesof simple structure, applicability to sheep in different bodily forms and suitability to substantial popularization.

Owner:LINYI UNIVERSITY

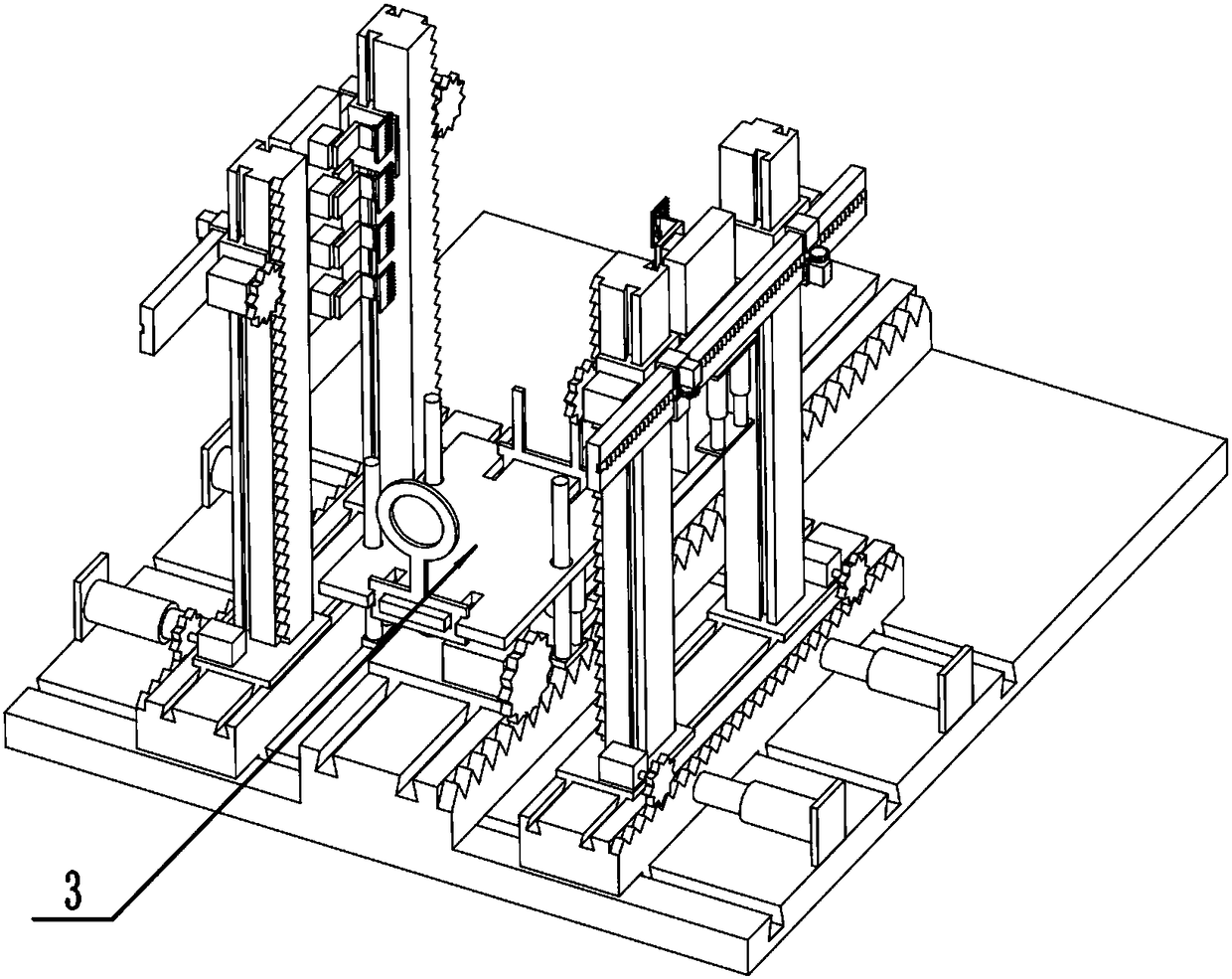

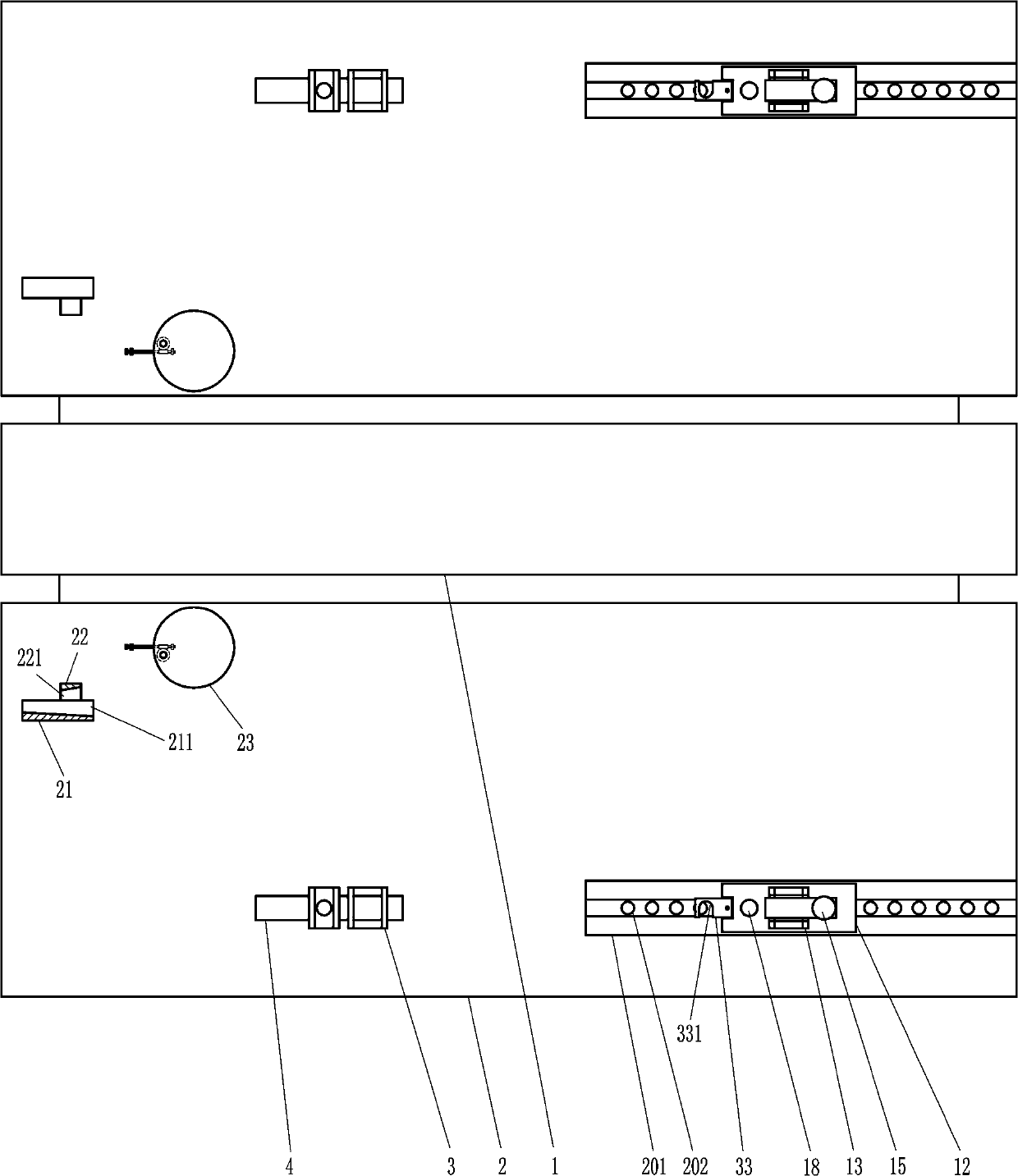

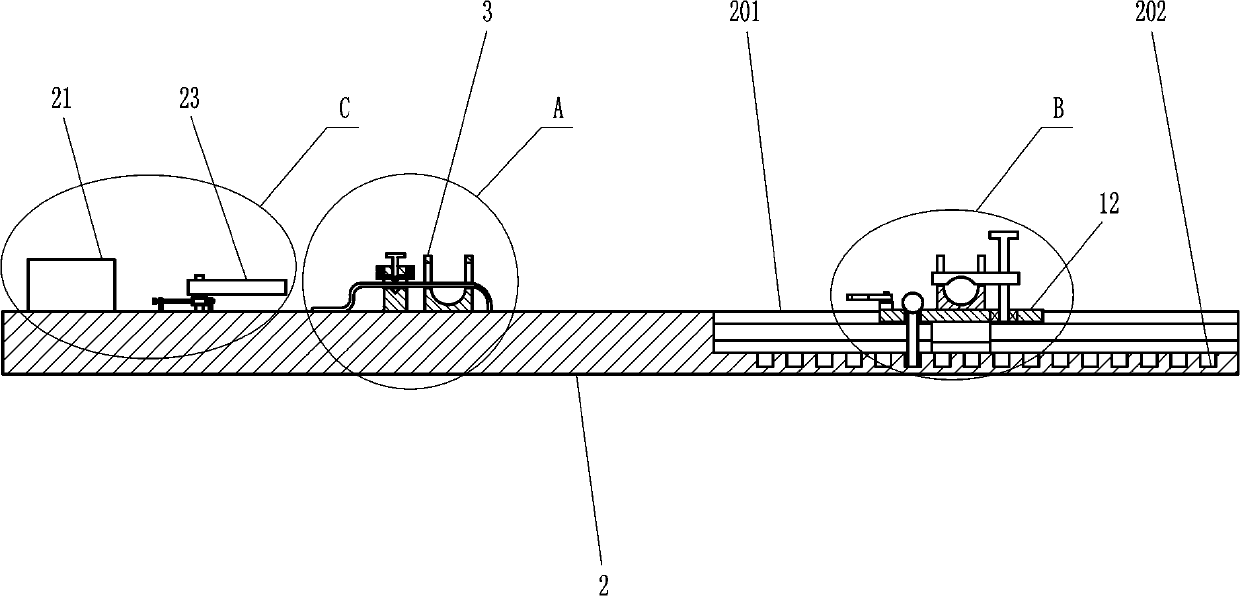

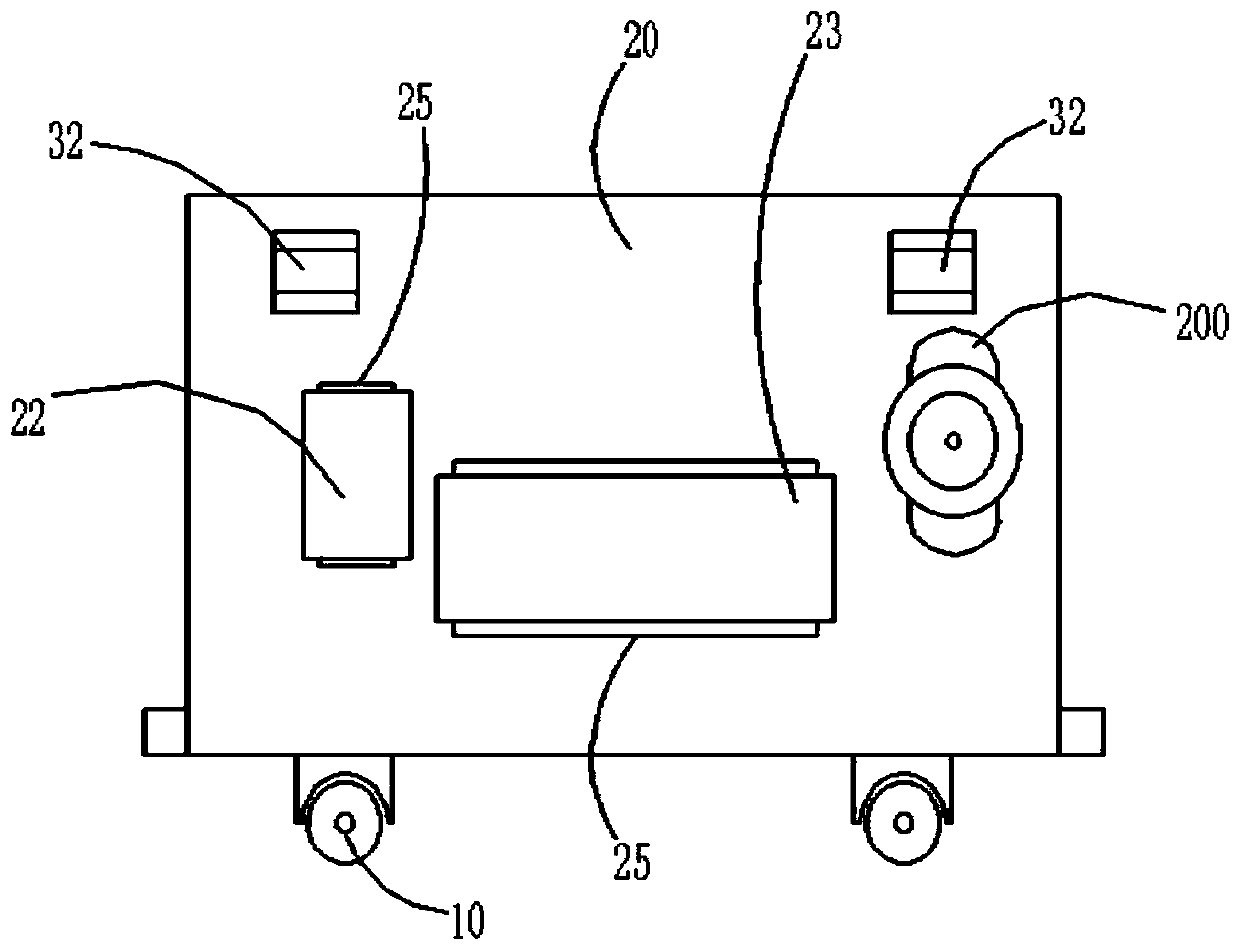

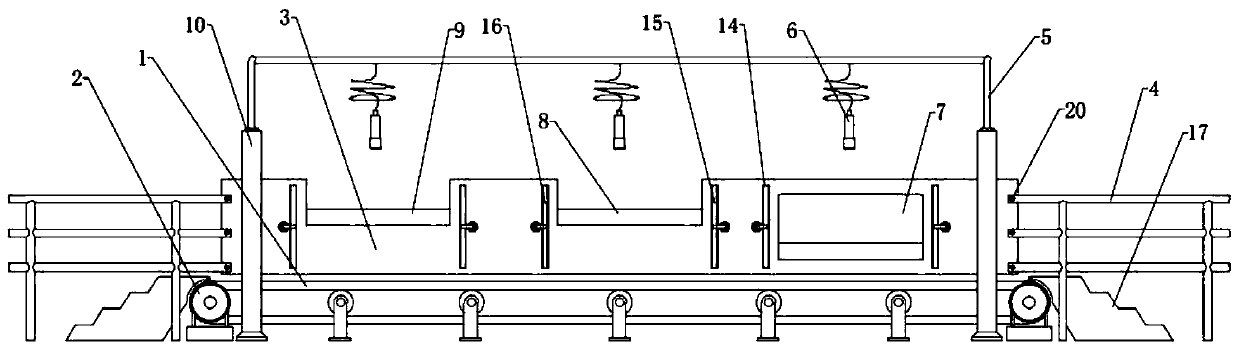

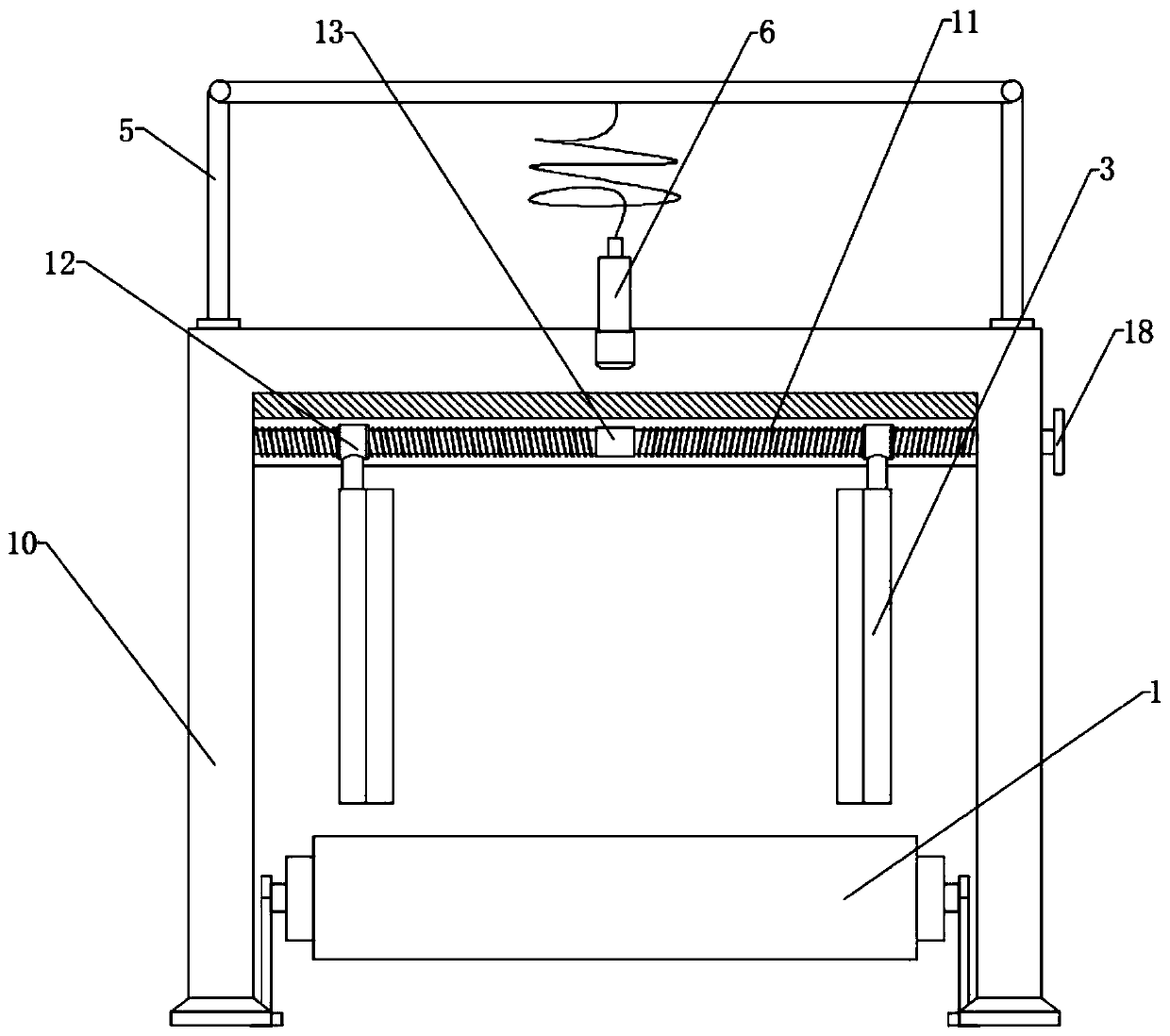

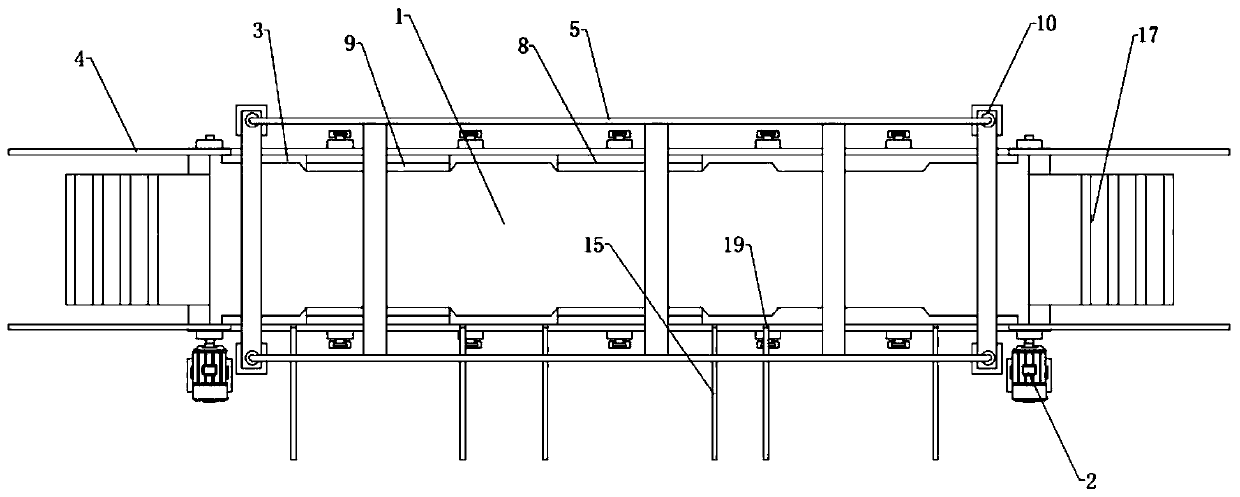

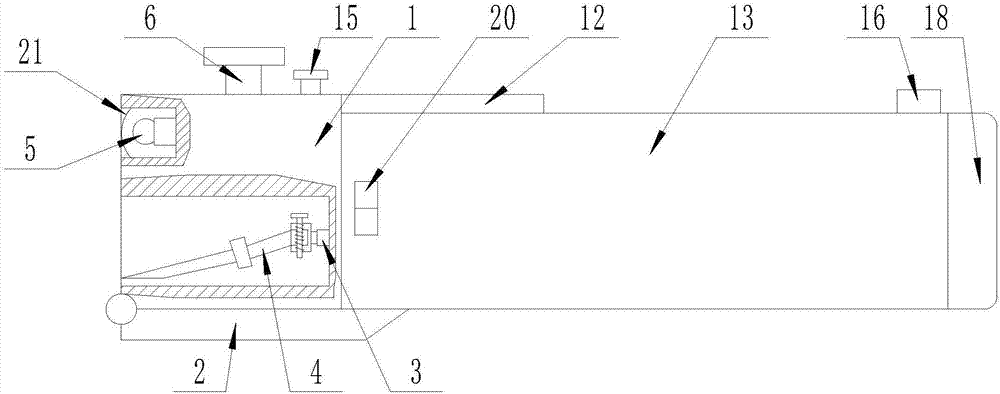

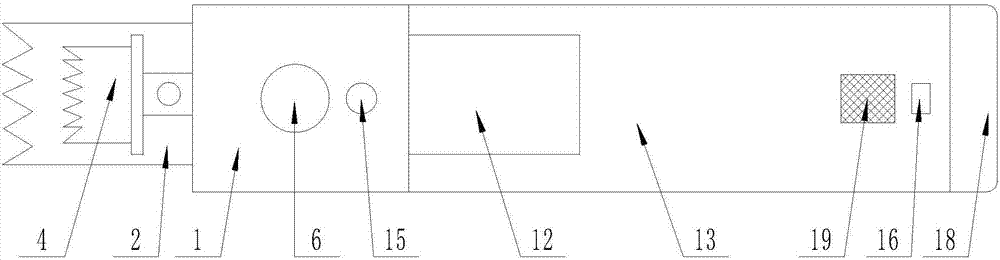

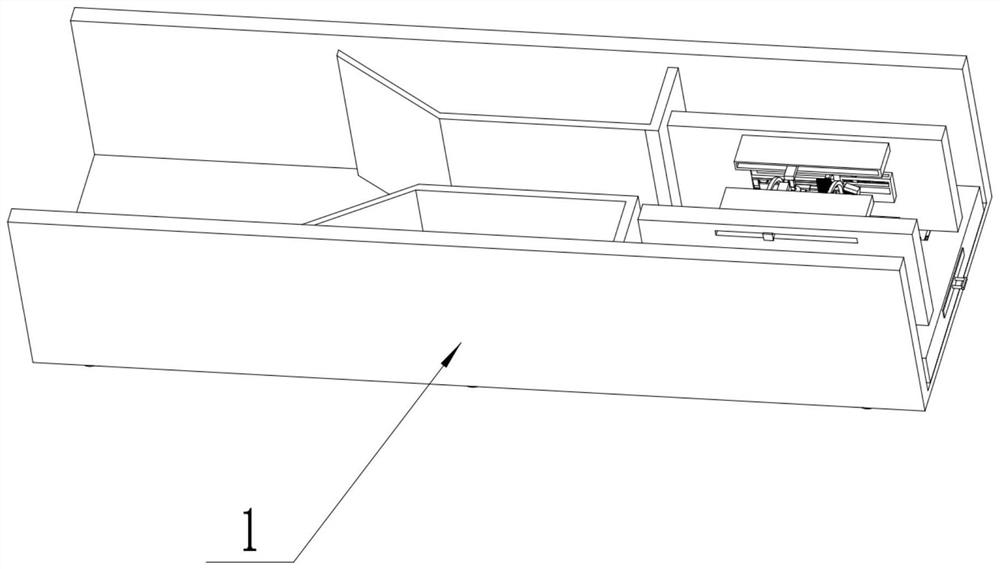

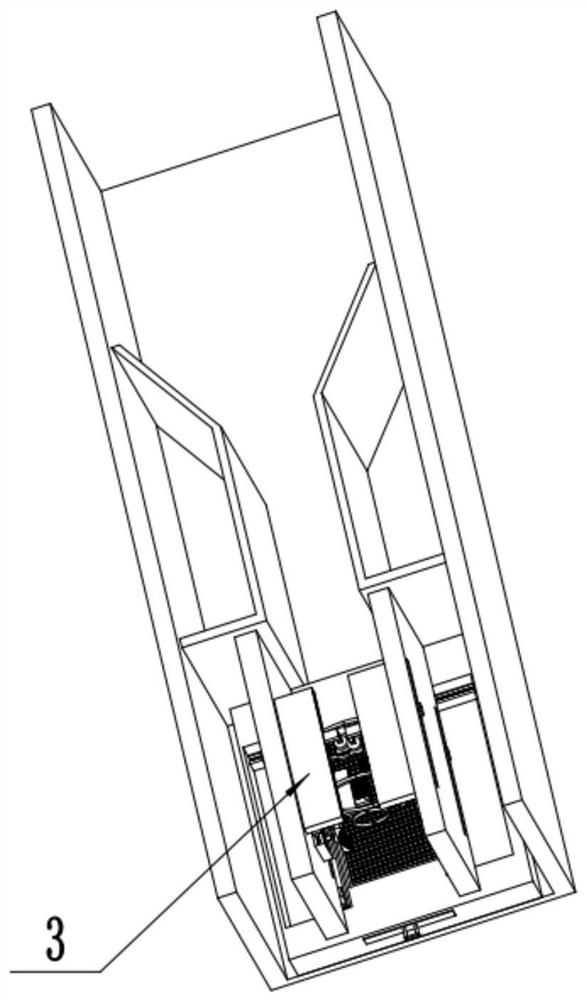

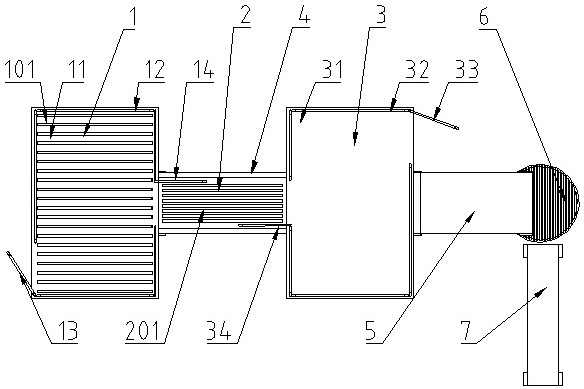

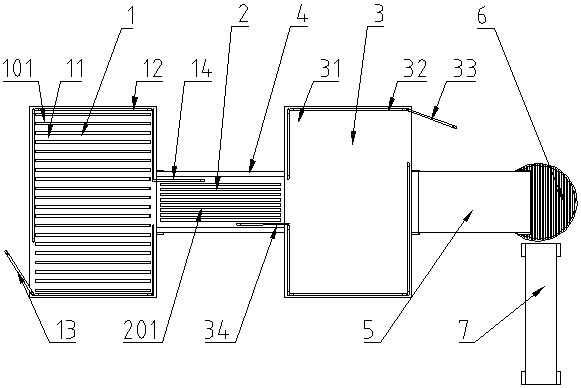

Multifunctional auxiliary shearing device for sheep breeding

ActiveCN111590645AHigh degree of automationChange in controlMetal working apparatusOther apparatusAnimal scienceElectric machinery

The invention discloses a multifunctional auxiliary shearing device for sheep breeding. The multifunctional auxiliary shearing device for sheep breeding is mainly composed of a horizontally arranged conveying device and a support installed outside the conveying device. The main body of the conveying device is a plate-type conveyer belt. The two ends of the plate-type conveyer belt are provided with a pair of traction motors correspondingly, and the traction motors are connected with the plate-type conveyer belt. The two sides of the plate-type conveyer belt are provided with a pair of drivingguardrails correspondingly. The multifunctional auxiliary shearing device for sheep breeding has the beneficial effects that the automation degree is high, operation and control are convenient, sheepin shearing can be effectively fixed, so that multidirectional multi-station assembly line operation is achieved, and the overall efficiency of sheep shearing is improved; and besides, the bodies of the sheep are limited in a side guard manner, the width is adjusted through an interval adjusting structure to be matched with the sheep of different body forms, the overall equipment avoids the harm to the sheep and a worker, sheep shearing operation is facilitated, and the shearing efficiency is improved.

Owner:河南中羊牧业有限公司

Novel electric sheep shears

The invention discloses novel electric sheep shears. The novel electric sheep shears comprise a tool bit. The lower end of the surface of the left side of the tool bit is hinged to combing teeth. A rectangular groove is machined in the surface of the left side of the tool bit and located above the combing teeth. A telescopic rod is arranged in the rectangular groove. The surface of the left side of the telescopic rod is movably connected with a blade. A first round groove is machined in the upper end of the surface of the left side of the tool bit. An LED energy-saving lamp is arranged in thefirst round groove. An opening is machined in the upper surface of the tool bit. A gap adjusting rotary knob is arranged at the opening. The surface of the right side of the tool bit is fixedly connected with a handle. A first groove is machined in the lower surface of the handle. A driving motor is arranged in the first groove. The novel electric sheep shears have the beneficial effects that theinjury to the ears of people can be reduced, the novel electric sheep shears still can be used during power off, new energy is used, the novel electric sheep shears can independently serve as an electric torch for illumination, the dual-purpose effect is realized, timing and time telling are achieved, the novel electric sheep shears can remind people of proper rest, the blade can be replaced anytime, and the time spent on grinding of the blade is reduced.

Owner:SHANGHAI ZHENGYU MACHINERY CO LTD

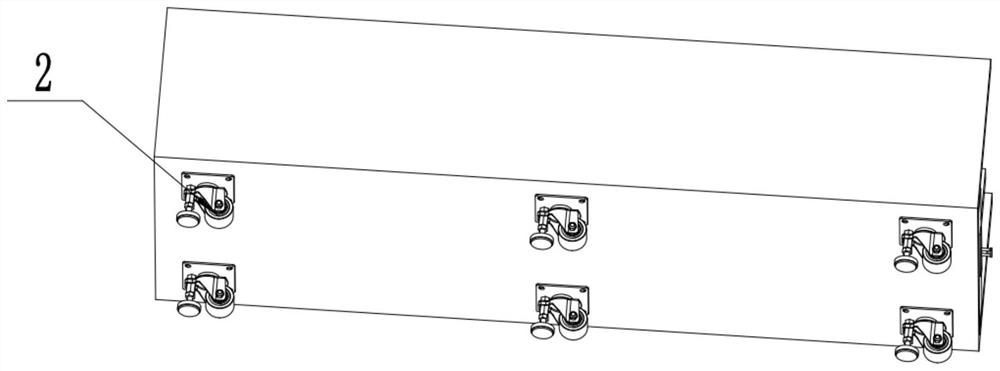

Wool shearing equipment

InactiveCN112470986AReduce the chance of injuryAvoid clampingOther apparatusTaming and training devicesEngineeringStructural engineering

The invention discloses wool shearing equipment. The wool shearing equipment comprises a moving number limiting shell, moving wheels and a working plate, the working plate comprises a power transmission mechanism, a base plate working mechanism, a side shell, a neck wool shearing mechanism, a sheep body shearing mechanism and a fixing frame, the upper end surfaces of the moving wheels are fixedlyconnected to the lower end surface of the moving number limiting shell, the working plate is fixedly arranged on the bottom end surface of the inner side of the moving number limiting shell, the powertransmission mechanism is fixedly connected to the inner side end surface of the side shell, and the fixing frame plays a role in fixing sheep. The wool shearing equipment aims at solving the technical problem and has the advantages that automatic wool shearing is realized, and the wool shearing efficiency is improved; and a rear sheep body fixing frame, a sheep neck fixing frame and a front sheep body fixing frame are adjusted to adapt to the size of the sheep, then fixing is conducted, and the situation that the sheep are too large to be pinched or too small to be unable to be clamped can be avoided.

Owner:张志锋

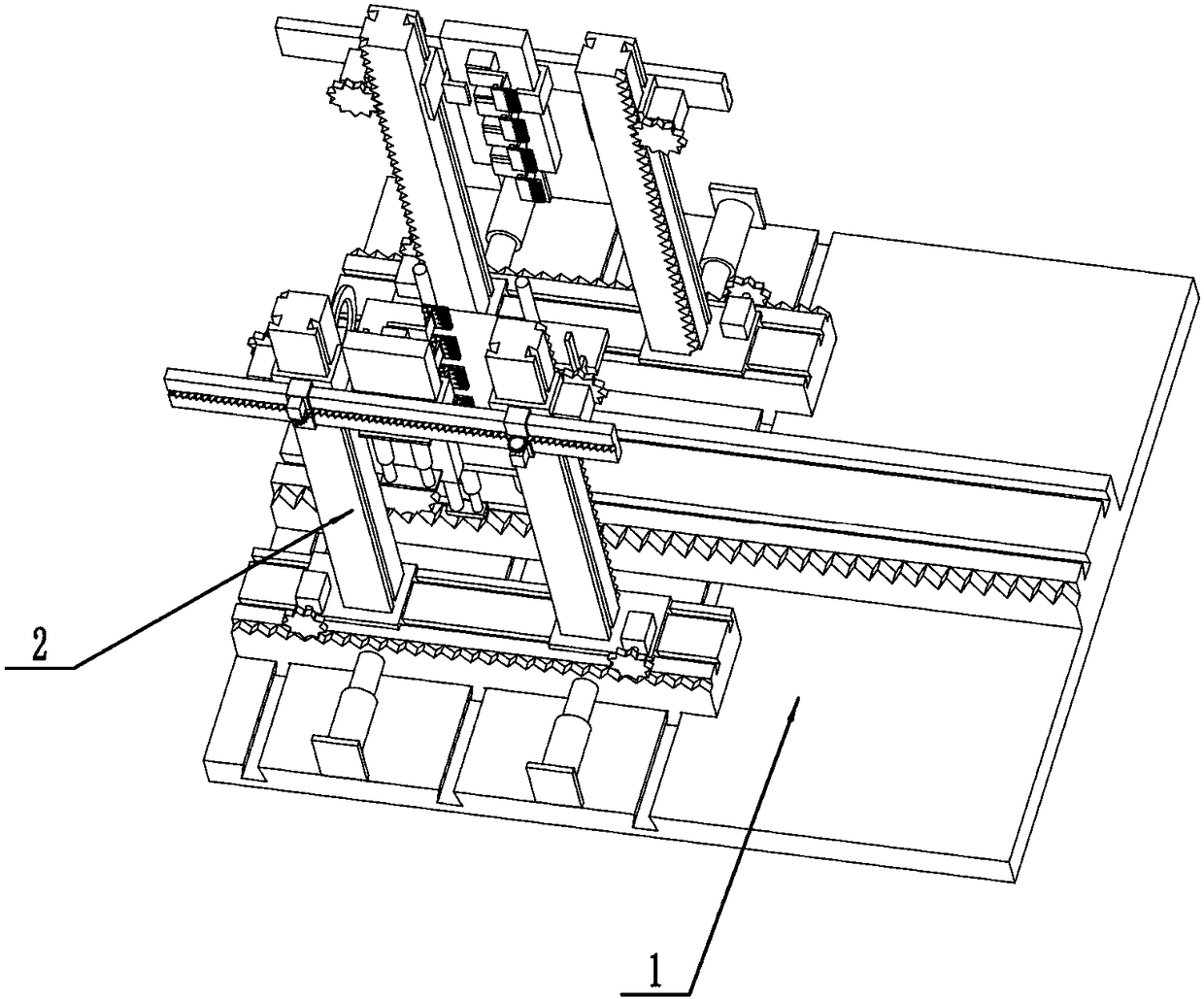

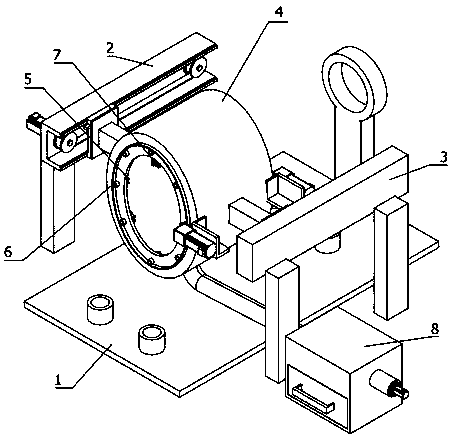

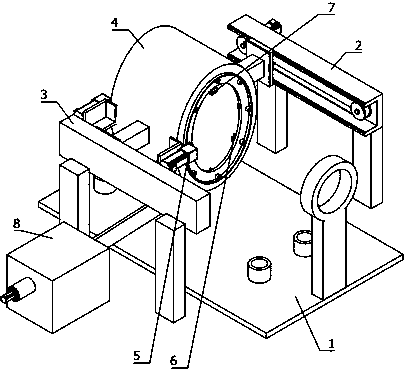

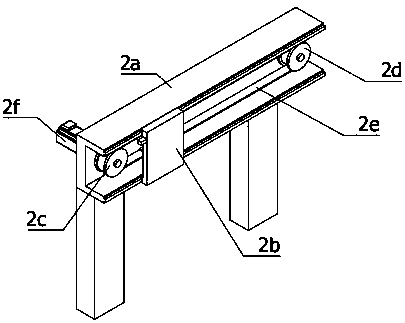

Automatic wool shearing robot

InactiveCN111011243AAvoid pollutionIncrease productivityGrooming devicesControl engineeringAgricultural engineering

The invention relates to the field of an agriculture-related robot, in particular to an automatic wool shearing robot. The automatic wool shearing robot comprises a fixing mechanism, a linear driver,a sliding table, a casing, a chain wheel transmission mechanism, a chain wheel power mechanism, a wool cutting mechanism and a wool extraction mechanism, wherein the linear driver and the sliding table are respectively positioned at two sides of the casing; the fixing mechanism is positioned at the bottom of the casing; the chain wheel transmission mechanism is arranged inside the casing; the chain wheel power mechanism is arranged on the casing; the work end of the chain wheel power mechanism is respectively connected with the stress end of the chain wheel transmission mechanism; the wool cutting mechanism is arranged at the work end of the chain wheel transmission mechanism; and the work end of the wool extraction mechanism is arranged at the bottom of the casing. The automatic wool shearing robot using the technical scheme has the advantages that the surrounding wool shearing can be realized on a sheep body, so that the work continuity is realized; the production efficiency is greatly improved; wool can be timely recovered after being cut; and the wool pollution and the risk of wool inhalation by people due to disordered flying of miscellaneous wool are avoided.

Owner:陶伟

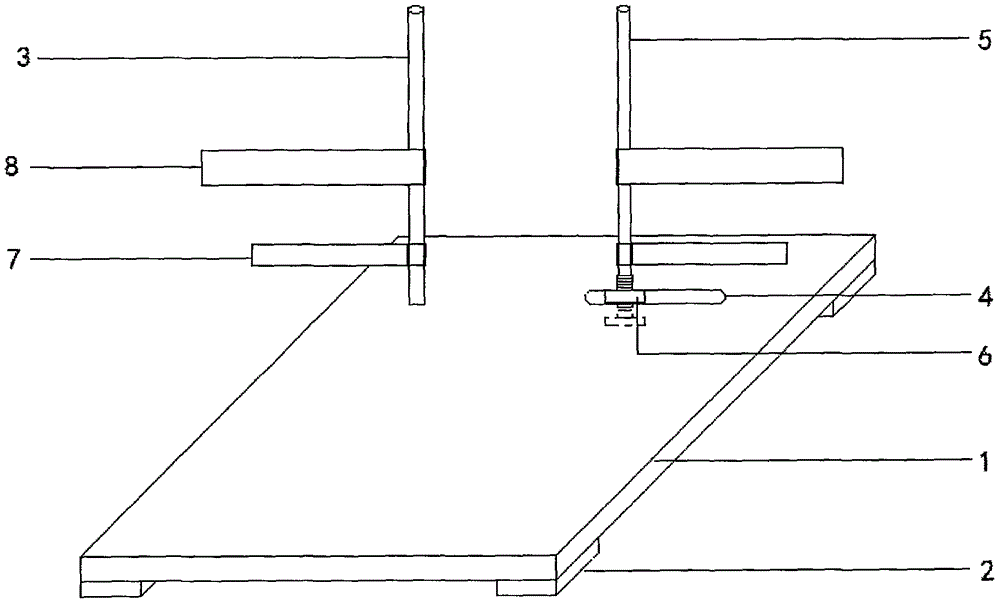

Sheep shearing stand

InactiveCN106489771ASimple structureEasy to useOther apparatusGrooming devicesEngineeringSheep shearing

The invention discloses a sheep shearing stand which is particularly suitable for being used during sheep shearing. The structure of the sheep shearing stand is that a cubic base is arranged; supporting legs are arranged at the four corners of the lower surface of the base; a fixed vertical rod is arranged on the left side of the front end of the upper surface of the base, and a through slot is formed in the right side of the front end of the upper surface of the base; a screw rod is arranged inside the through slot in a penetrating manner; a pressing nut is arranged on the screw rod; the screw rod can slide left and right in the through slot; fixed binding bands I are arranged at the lower ends of the vertical rod and the screw rod, and binding bands II are arranged at the middle ends of the vertical rod and the screw rod; the binding bands II can slide up and down on the vertical rod and the screw rod; bonding buckles are arranged on the binding bands I and the binding bands II. The sheep shearing stand is simple in structure, convenient to use, time-saving and labor-saving, avoids the economical loss and is easy to popularize.

Owner:李红光

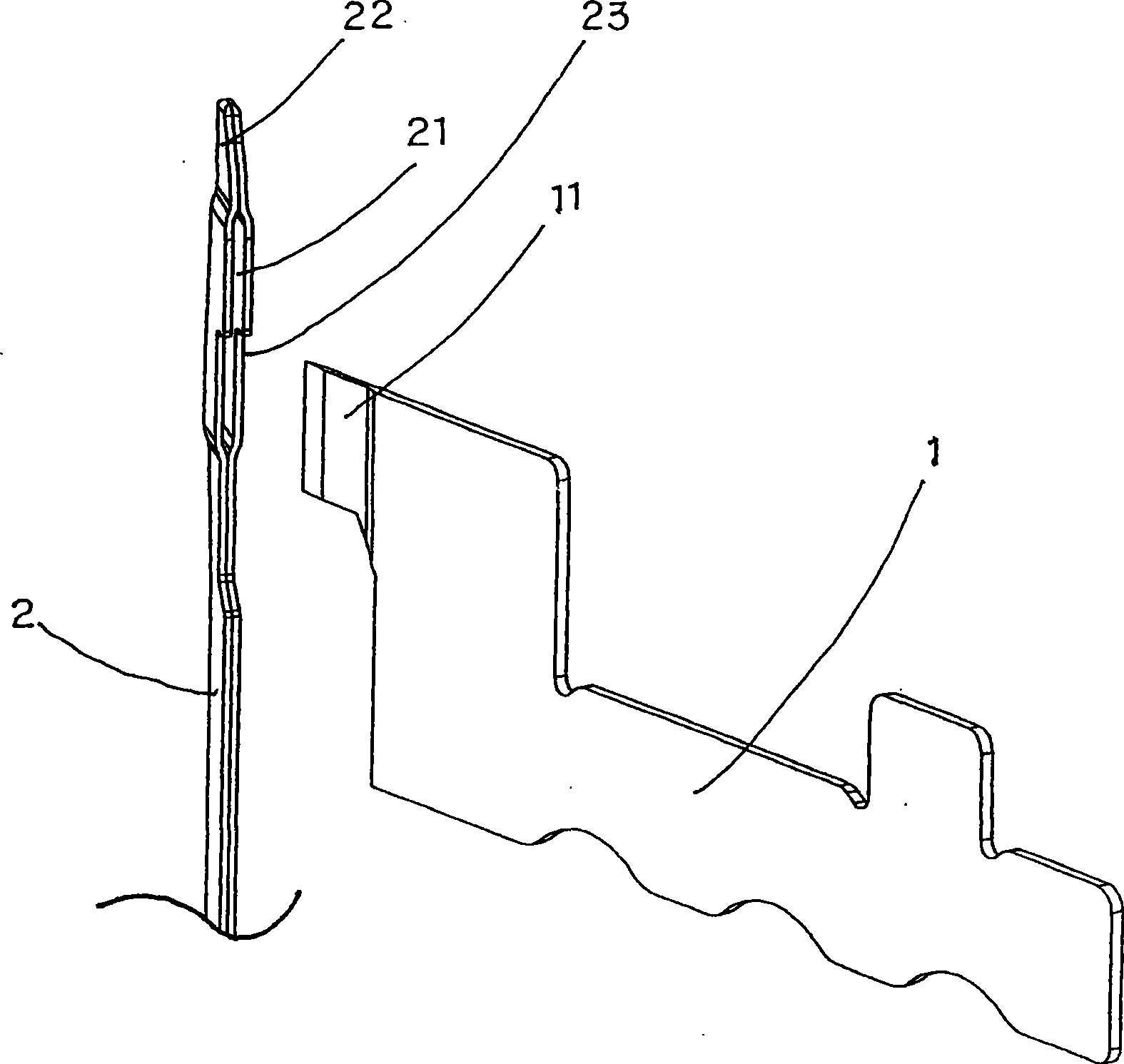

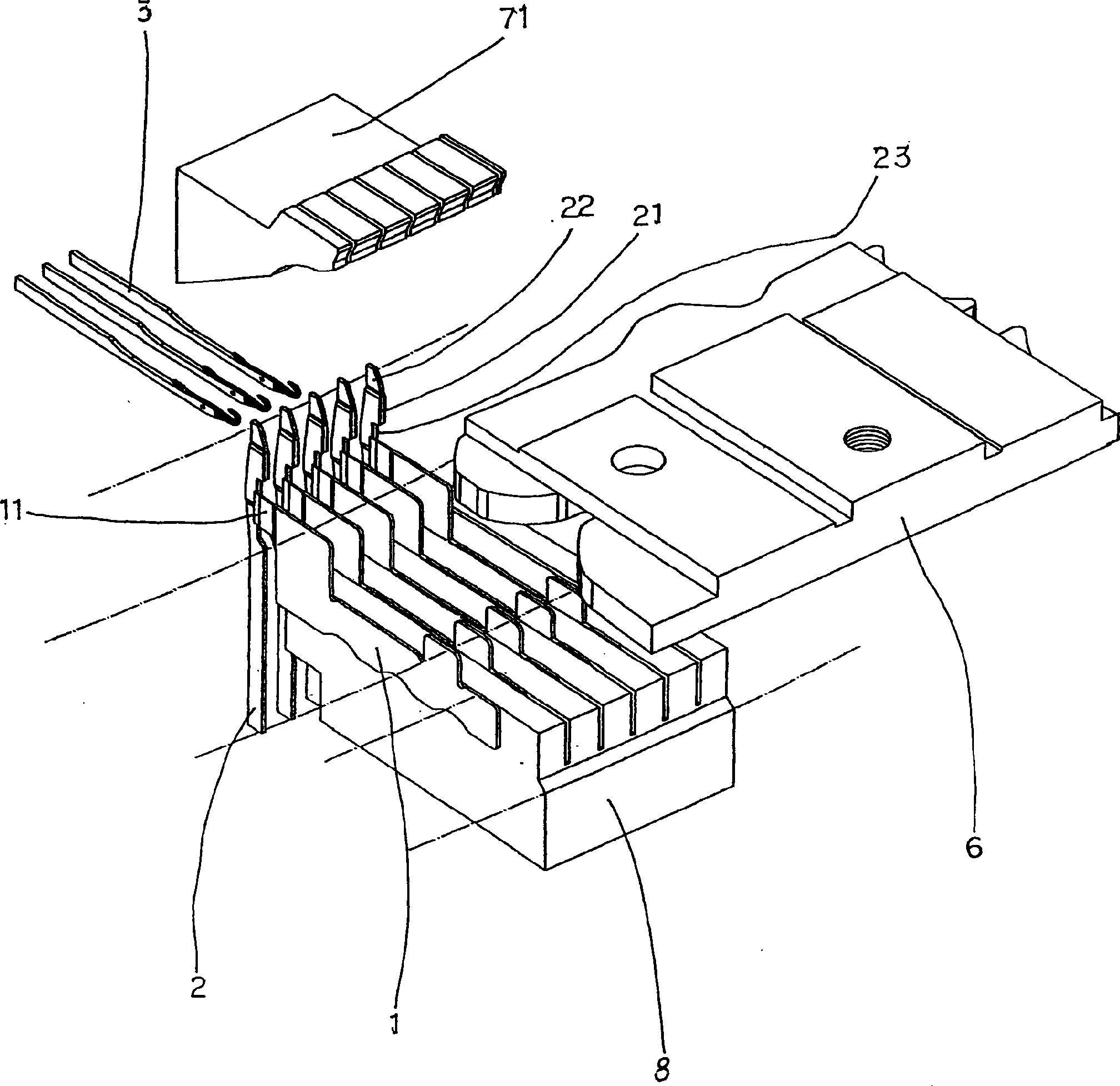

Sheep shearing unit of knitting machine for tubular knitting towel

The invention relates to a shearing device of a circular towel knitting machine. The front end of a sinker is provided with a thinner blade to form a yarn cutting knife; a through hair cutting opening is arranged at a proper position at the top of a wire raising needle; when a knitting needle hook draws yarns to knit a towel cloth cover, a hair loop is formed in a groove of the wire raising needle; the yarn cutting knife is moved forwards to make the blade penetrate into the hair cutting opening of the wire raising needle and to cut the hair loop yarns on the wire raising needle, so that the operations of knitting a hair loop cloth cover by the knitting needle hook and shearing are finished at the same time, wherein the blade angle of the yarn cutting knife is preferably 90 degrees. After the knitting needle hook draws yarns to knit a hair loop in the groove of the wire raising needle, the wire raising needle is dropped to pull down the hair loop in the groove; and then the yarn cutting knife is moved forwards to penetrate into the hair cutting opening of the wire raising needle so as to cut off the hair loop and achieve the aim of shearing.

Owner:洪荣豪

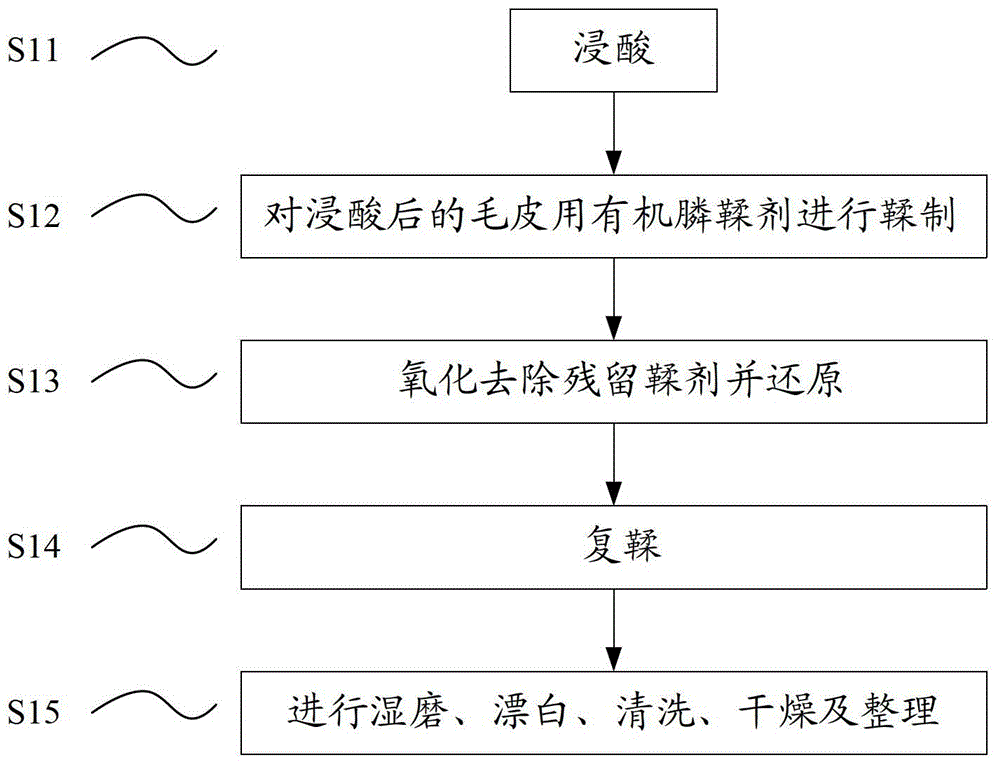

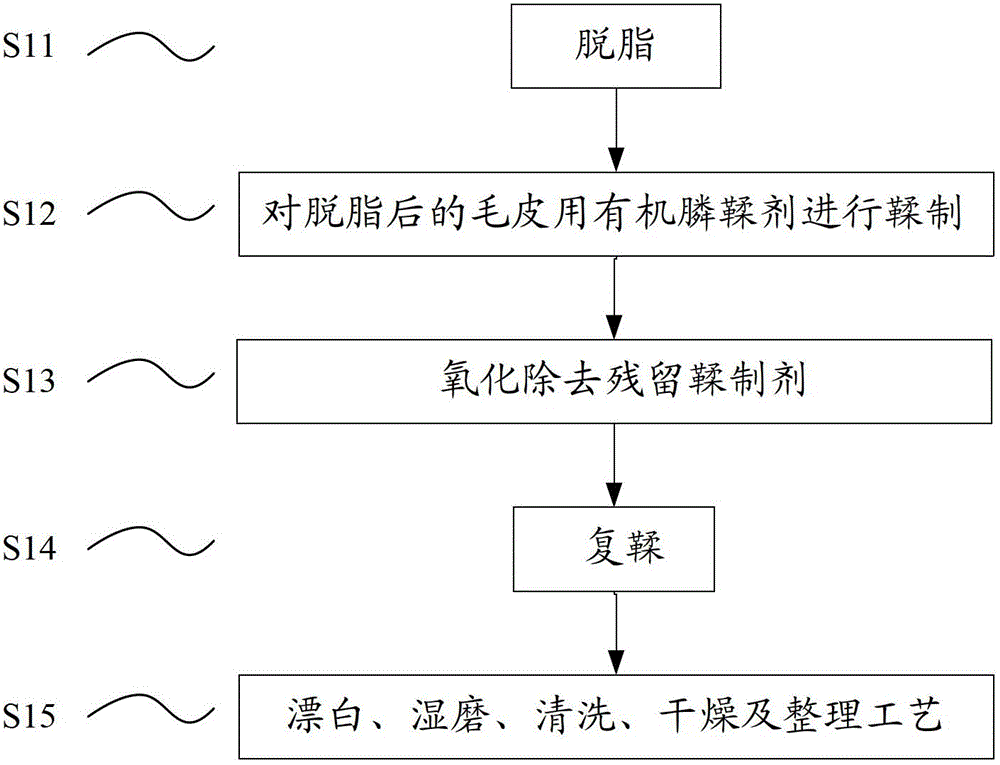

A kind of tanning method of sheep shearing

ActiveCN103710474BQuality improvementImprove pickling processTanning treatmentPre-tanning chemical treatmentOrganic acidOxidation-Reduction Agent

The invention discloses a tanning method of shorn sheepskin. The method comprises: 11) a step of dipping with an acid, namely, a step of adding water into a paddle, then adding industrial salt, adding an organic acid into the solution to obtain an acid dipping solution, and finally dipping fur into the acid dipping solution; 12) a step of tanning the fur after having been dipped in the acid dipping solution; 13) a step of oxidizing to remove residue of a tanning agent, and then subjecting the fur to a reduction technology; 14) retanning the fur after the oxidation and reduction steps; and 15) subjecting the fur to wet grinding, bleaching, cleaning, drying and finishing processes. According to the tanning method, the acid dipping step in tanning methods of shorn sheepskin is improved and sulfuric acid conventionally used in the acid dipping step is replaced by formic acid. The formic acid used in the tanning method provided by the invention belongs to organic acids. Compared with the fur dipped with an inorganic acid, the fur dipped with an organic acid has thick, solid and plump fur plate after the tanning step is finished and the quality of the fur plate is improved.

Owner:隆丰革乐美时尚有限公司

A method for recycling sheep shearing dyeing board waste liquid

ActiveCN109182624BReduce water consumptionFulfil requirementsTanning treatmentLeather/skins/hides/pelt chemical treatment apparatusActive agentEnvironmental engineering

Owner:隆丰革乐美时尚有限公司

A kind of preparation method of sheep shearing wax all-effect effect leather

ActiveCN107338337BGood color fastness to lightGood color fastness to wet and dry rubbingWax coatingsFur mechanical treatmentBiotechnologyColour fastness

The invention provides a preparation method for chenille wax change effect leather. The preparation method comprises the following steps that (1) chenille fur after retanning and dyeing is neatened for the first time; (2) the fur after processing in the first step is subjected to staking and leather buffing and then is neatened for the second time; (3) a top side of the fur after processing in the second step is subjected to butt oar spraying, color paste spraying and top oar spraying in sequence; (4) after the fur after processing in the third step is milled, the wax change effect leather is obtained. A wax color change effect glaze can be obtained from a chenille flesh side. A product has good color fastness to light, dry and wet rubbing color fastness and PVC transfer resistance.

Owner:隆丰革乐美时尚有限公司

A kind of sheep shearing fixing device for animal husbandry breeding

ActiveCN109717092BImprove qualityImprove comfortOther apparatusTaming and training devicesAnimal scienceZoology

The invention discloses a shearing shearing fixing device for animal husbandry, which comprises a fixed base plate, a surrounding baffle, a fixing component, and an adjusting strut; the surrounding baffle includes a fixed fence and a limit fence; the fixing component includes a neck fixing ring 1. Sheep limb fixing seat and fixed buckle, the fixed fence is hinged on the fixed bottom plate, the sheep manure collection box and the wool collection box are arranged on the fixed fence, the limit fence is snapped with the fixed fence, and the neck fixed ring is set On the fixed enclosure, the limb fixing seat is arranged on the inner side of the fixed enclosure, the fixed buckle is arranged on the outer surface of the fixed enclosure, and the adjusting strut is arranged at the joint between the fixed enclosure and the fixed bottom plate, and the adjusting strut is used to adjust the fixed enclosure. The angle of inclination of the block; the present invention has a simple structure, can be applied to sheep of different sizes, and is suitable for mass promotion.

Owner:LINYI UNIVERSITY

Medicine for treating post-shearing wounds of sheep and preparation method thereof

InactiveCN107648266AEasy to prepareEasy to operateOrganic active ingredientsAerosol deliveryVegetable oilVeterinary Drugs

The invention discloses a medicine for treating post-shearing wounds of sheep and a preparation method thereof, which belong to the technical field of veterinary medicines. The main ingredients of themedicine include: 800ml to 1200ml of miticide bath wash, 800ml to 1200ml of phoxim solution, 800ml to 1200ml of 75-percent alcohol, 800g to 1200g of refined trichlorfon, 300g to 600g of ichthammol and 800g to 1200g of boiled oil. The medicine for treating post-shearing wounds of sheep disclosed by the invention is easy to prepare and convenient to operate, the sources of the materials are wide, the cost is low, the medicine for treating post-shearing wounds of sheep is safe and effective, and has the effects of disinfection, antisepsis, insect killing, itch relieving, heat clearing, toxicityremoval, wound healing acceleration and body immunity enhancement, the curative rate is up to 80 percent or more, and clinical practice proves that the composition achieves a relatively satisfactory therapeutic effect in treatment.

Owner:甘肃省绵羊繁育技术推广站

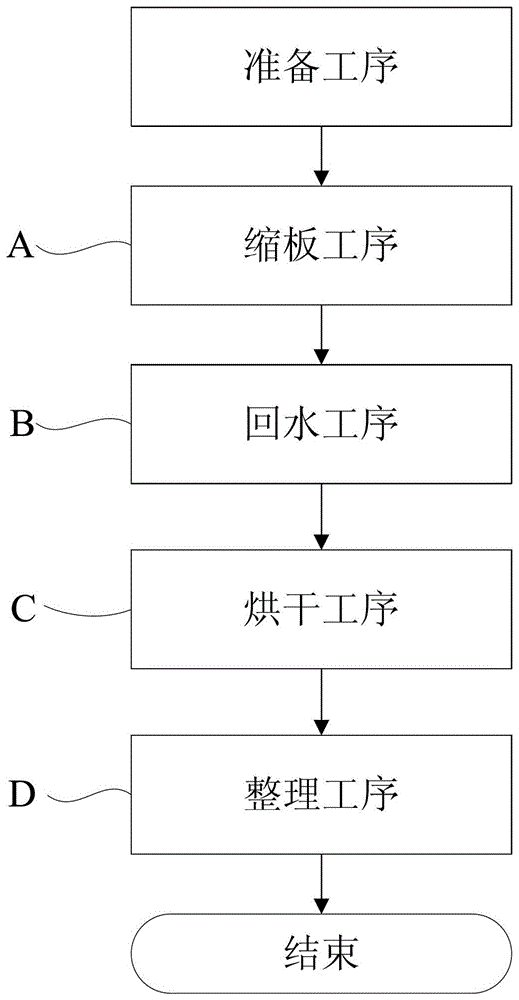

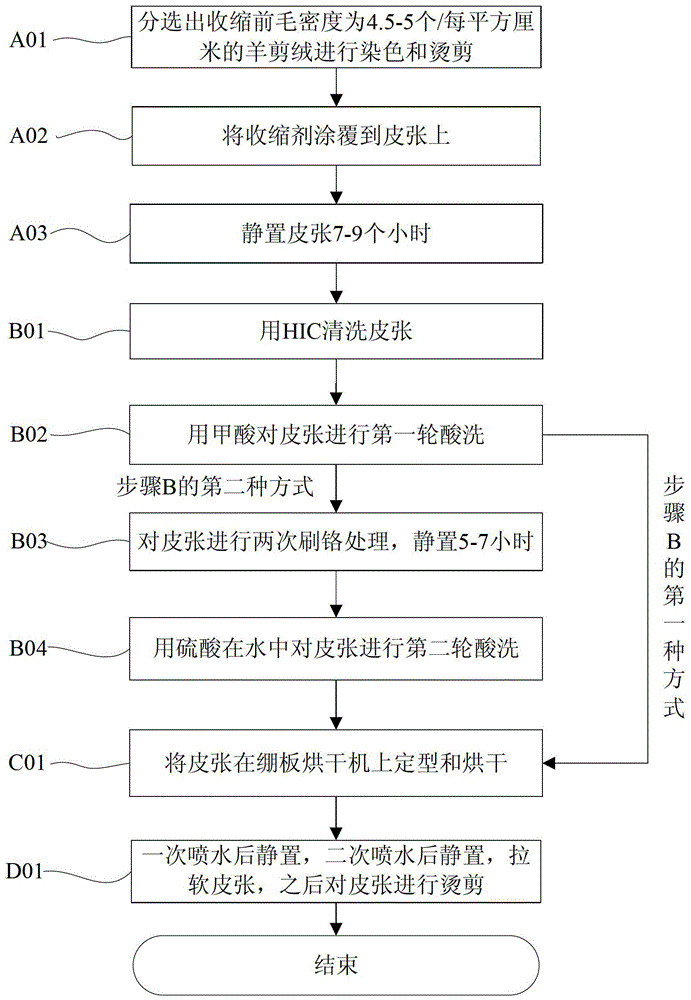

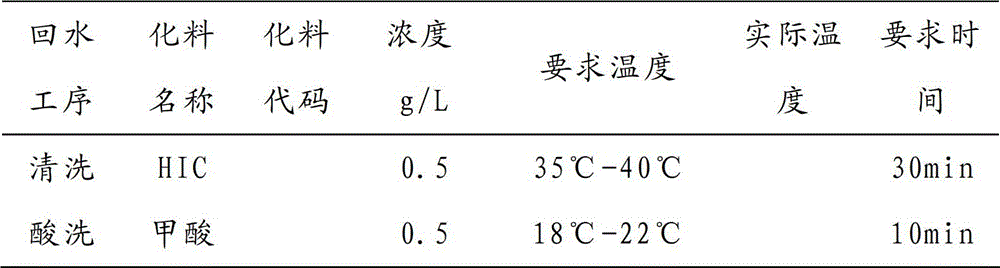

Clean production method of sheep shearlings for high-density bed blankets

ActiveCN112481428BFast convergenceImprove the effect of shrinkage special chemicalTanning treatmentPre-tanning chemical treatmentPulp and paper industryBiology

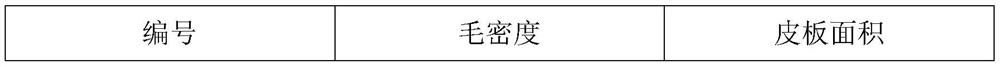

The invention belongs to the technical field of sheep shearing bed blanket production, and discloses a clean production method for sheep shearling for high-density bed blankets, comprising the following steps: 1) washing, removing flesh and shearing; 2) soaking in water; 3) ) degreasing; 4) treatment of increasing the gross density: adding the hide into the astringent tanning agent bath, stirring evenly, soaking for 15 hours; the preparation method of the astringent tanning agent bath is: slowly adding 5 grams of sulfuric acid to 1000 grams of In the tanning agent SELLATAN LV conc.liq, stir evenly to make a shrinkage special chemical, and dilute the shrinkage special chemical 50 times with water to obtain an astringent tanning agent bath; 5) Brush chrome; 6) Pickling; 7) Shake 8) dry cleaning; 9) scalding and shearing. The production method of the invention can increase the wool density of sheep shearling to more than 7.

Owner:隆丰革乐美时尚有限公司

A flipping device for shearing sheep's hooves

ActiveCN111134888BEasy to trimReduce labor intensityAnimal fetteringRolling-element bearingStructural engineering

The invention relates to the technical field of sheep's hoof nail clipping, and discloses a flipping device for sheep's hoof nail clipping, which includes a U-shaped fixing plate, and support plates are fixed on the left and right sides of the lower surface of the U-shaped fixing plate, and Both the inner walls are rotated by the first rolling bearing and are provided with rotating shafts, and the opposite ends of the two rotating shafts are fixed with the first connecting rod arranged vertically, and the ends of the two rotating shafts facing away from each other penetrate to the outside of the U-shaped fixed plate and the rod wall Both are equipped with a limit mechanism, the lower ends of the two first connecting rods are fixed with fixed blocks, the lower sides of the two fixed blocks are provided with bar-shaped grooves, and the inside of the two bar-shaped grooves is equipped with a moving mechanism, and the lower Both sides are provided with second connecting rods, the opposite sides of the lower ends of the two second connecting rods are fixed with connecting blocks, and the opposite sides of the two connecting blocks are fixed with arc splints. The invention is easy to operate and reduces the labor intensity of workers.

Owner:ANHUI PROVINCE TIANCHANG CITY ZHOUSHI SHEEP CO LTD

A kind of tanning method of sheep shearing

ActiveCN103725810BHarm reductionReduce pollutionTanning treatmentPre-tanning chemical treatmentFiberWet grinding

Owner:隆丰革乐美时尚有限公司

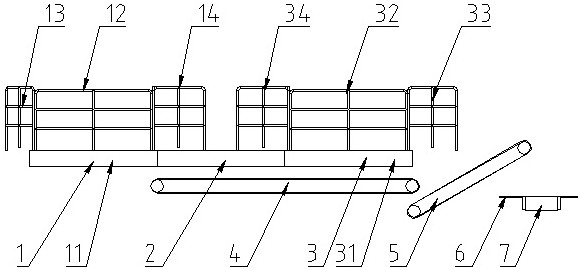

a sheep shearing farm

ActiveCN107821210BEasy to cleanReduce labor intensityOther apparatusGrooming devicesStructural engineeringMechanical engineering

The invention discloses a sheep shearing field, which comprises a pen to be sheared, a shearing platform and a pen for sheared sheep. The pen to be sheared includes a platform, a fence, an entrance gate and an exit gate. Fences are arranged around the platform, and the left lower part of the platform An entrance door is set on the side of the platform, an exit door is set on the side of the right middle part of the platform, and a shearing table is set in the middle part of the right side of the sheep-to-be-sheared pen. There is a conveyor belt conveyor directly below the spatial position of the circle, a diagonal belt conveyor is provided directly below the spatial position of the right end of the conveyor belt conveyor, and a sorting table is provided at the right bottom of the spatial position of the diagonal belt conveyor. There is a movable sorting belt conveyor; when in use, the wool cover is placed on the conveyor belt conveyor, thrown by the inclined belt conveyor, sorted by the sorting table, and sent to the packing place by the sorting belt conveyor, which reduces the labor of workers Strength; the present invention has the advantages of high sorting efficiency and reduced labor intensity of workers.

Owner:常州云鲲光电科技发展有限公司

A kind of fast soaking method for sheep shearing

ActiveCN105039606BReduce immersion timeShort immersion timePre-tanning chemical treatmentFiberAlkane

The invention discloses a quick soaking method of shorn sheepskin. The quick soaking method of shorn sheepskin includes the technical steps that (1) the water temperature is 38 DEG C, and 1 g of alkane sulfonate-like rewetting auxiliaries Feliderm MS Power, 1 g of scouring agents and 1 g of degreasing agents SE are added per liter of water for primary soaking; (2) the water temperature is 38 DEG C, 1.5 g of complex enzyme preparations DESOBATE DB and 0.5 g of degreasing agents SE are added per liter of water for pre-soaking; (3) the water temperature is 38 DEG C, 3 g of polyphosphoester-like soaking agents Feliderm SWP Powder and 1 g of interface surface active agents Borron SE are added per liter of water for soaking again; and (4) the soaked skin is fully washed with water of normal temperature, dirt is thoroughly washed away, and the next process is conducted after two hours of water control. By means of the quick soaking method of shorn sheepskin, the soaking time can be shortened, and the requirement of modern enterprises for shortening the production cycle is met; and the fiber loosening effect is high, water consumption can be remarkably reduced, and production efficiency is improved.

Owner:隆丰革乐美时尚有限公司

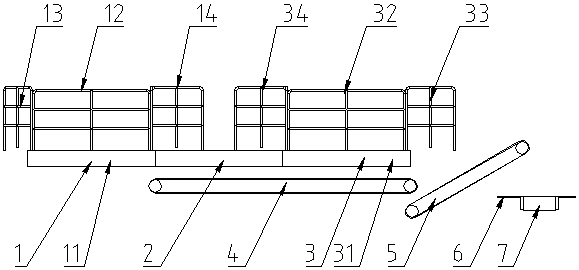

Sheep shearing field

ActiveCN107821210AEasy to cleanReduce labor intensityOther apparatusGrooming devicesEngineeringUltimate tensile strength

The invention discloses a sheep shearing field. The sheep shearing field includes a pen for sheep to be sheared, a shearing table, and a pen for sheared sheep; the pen for the sheep to be sheared includes a platform, a fence, an entrance door and an exit door; the fence is arranged around the platform; the exit door is arranged on a side surface of the lower left part of the platform; the exit door is arranged on a side surface of the central right part of the platform; the shearing table is arranged on the central part of the right side of the pen for the sheep to be sheared; the pen for thesheared sheep is arranged on the right side of the shearing table; a belt conveyor is arranged under a spatial position between the shearing table and the pen for the sheep to be sheared; an inclinedbelt conveyor is arranged under a spatial position of the right end of the belt conveyer; a sorting table is arranged on a lower right part of a spatial position of the inclined belt conveyor; and movable sorting belt conveyors are arranged around the sorting table. In use, wool is placed on the belt conveyor, is thrown by the inclined belt conveyor, is sorted by the sorting table, and is conveyedto a packaging portion via the sorting belt conveyor; the working load of workers can be reduced; the sheep shearing field is high in sorting efficiency, and can reduce the working load of the workers.

Owner:常州云鲲光电科技发展有限公司

Auxiliary fixing device for animal husbandry shearing sheep and its use method

ActiveCN107667901BEasy to cutThe cropping process is quietTaming and training devicesAnimal scienceCrop livestock

Owner:肖天琪

A kind of preparation method of sheep shearing pulp leather product

ActiveCN107338338BImprove processing efficiencyImprove efficiencyFur shearingFur dressingWaxPulp and paper industry

The invention provides a preparation method for a chenille oar leather product. The preparation method comprises the following steps that (1) chenille fur after retanning and dyeing is neatened for the first time; (2) the fur after processing in the first step is subjected to staking and leather buffing and then is neatened for the second time; (3) a top side of the fur after processing in the second step is subjected to bottom oar spraying, color paste spraying and top oar spraying in sequence; (4) after the fur after processing in the third step is milled, wax change effect leather is obtained. A wax color change effect glaze can be obtained from a chenille flesh side. The product has good color fastness to light, dry and wet rubbing color fastness and PVC transfer resistance.

Owner:隆丰革乐美时尚有限公司

A kind of processing method of sheep suede leather

The invention discloses a processing method for sheared sheep skin leather. The method comprises the step of performing board shrinkage on a piece of sheared sheep skin subjected to preparation, wherein a roll coater is used, a shrink agent is added into the roll coater, and is coated on the sheared sheep skin leather by the roll coater, and then the leather is subjected to still standing, backwater, drying and finishing to obtain a sheared sheep skin product. According to the method, the roll coater is used to uniformly coat the shrink agent on the sheared sheep skin leather, and the shrink agent enables the leather to shrink, and can fully permeate into the leather through the still standing of the leather, so that the leather can shrink further to obtain required sheared sheep skin with higher wool density, and a problem that raw materials of the high-density sheared sheep skin are less, which limit the mass processing and production of the required sheared sheep skin leather with higher wool density in the prior art is solved.

Owner:隆丰革乐美时尚有限公司

Preparation process of short wool tops in 18.5 microns

The invention relates to a preparation process of short wool tops in 18.5 microns. The preparation process comprises the following specific steps: 1, wool selection: 50%-60% of lamb wool, 30%-40% of weaned lamb wool and 5%-10% of early sheared wool; 2, opening, wool washing and drying: respectively carrying out opening, washing and drying on the three kinds of wool in the step 1, controlling the wool washing temperature of the early sheared wool to be 42-46 DEG C, the wool washing machine being provided with 3-5 tanks, a washing agent being not added into the first tank and the last tank, controlling the washing temperature of the lamb wool and the broken lamb wool to be 35-40 DEG C, controlling the number of the tanks of the wool washing machine to be 4-5, the first tank and the last tankbeing filled with clear water, adding the washing agent into the rest tanks, and drying the cleaned wool; 3, mixing the wool; and 4) carrying out pre-gilling, combing and post-gilling processes. According to the preparation process of the short wool tops in 18.5 microns, the wool tops are stable in quality and belong to the category of qualified products, the supply amount is increased, the market requirement is met, the production efficiency is improved, and the energy consumption is reduced.

Owner:TIANYU WOOL IND ZHANGJIAGANG FREE TRADE ZONE CO LTD

Manufacturing process of hair tip effect by electroplating method

ActiveCN112481427BImprove plating efficiencyFeel goodTanning treatmentPre-tanning chemical treatmentWet grindingMaterials science

The invention discloses an electroplating hair tip effect production process, which includes fur treatment, fur tanning treatment, electroplating pretreatment, electroplating and other steps; fur tanning treatment includes water immersion, tanning, retanning, wet grinding, cleaning and drying. The present invention uses the electroplating method to carry out electroplating on the hair surface of sheep shearling to form a hair tip effect with metallic luster; in the process of retanning and fatliquoring, a waterproof fatliquoring agent is used, which greatly improves the efficiency of electroplating on the wool surface. After completion, 200°C high-temperature scalding technology is used to improve the feel, brightness and wet and dry wiping performance of the wool surface.

Owner:隆丰革乐美时尚有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com