Sheep shearing field

A technology of sheep shearing and sheep pen, which is applied in the field of sheep shearing, can solve the problems of high labor intensity, heavy labor, and lower wool quality, and achieve the effect of reducing labor intensity, reducing labor intensity, and improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

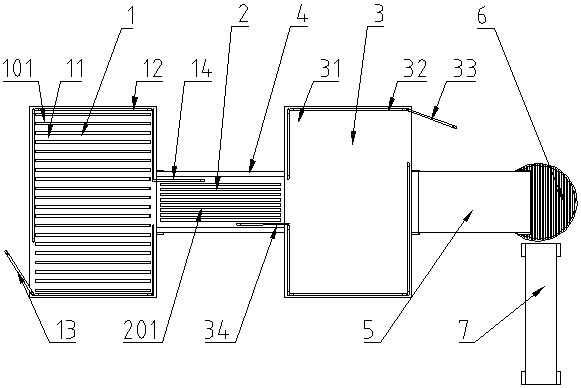

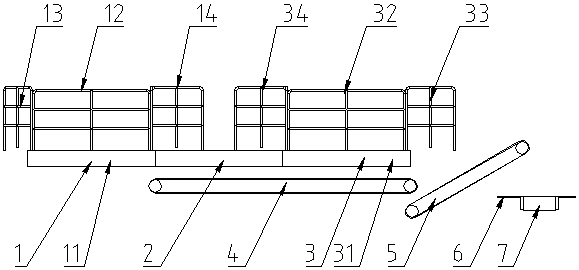

[0017] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

[0018] Such as figure 1 , figure 2 As shown, a sheep shearing field includes a sheep-to-be-sheared circle 1, a shearing platform 2 and a sheep-sheared circle 3, and the sheep-to-be-sheared circle 1 includes a platform 11, a fence 12, an entrance gate 13 and an exit gate 14. The platform 11 is provided with a horizontal rectangular strip hole 101, which is used to drop the feces and other sundries produced by the sheep in the sheepfold to the lower space, and at the same time keep the sheepfold 1 to be sheared clean. The platform 11 is surrounded by fences 12. The side of the lower left part of the platform 11 is provided with an entrance door 13, and the side of the right middle part of the platform 11 is provided with an exit door 14, and the right middle part of the sheep pen to be sheared 1 is opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com