Sheep shearing unit of knitting machine for tubular knitting towel

A technology of circular knitting towels and knitting machines, which can be used in knitting, textiles, papermaking, and cut pile loops, etc. It can solve the problems of high cost, unsatisfactory, and blade wear, and achieve the effect of simple structure and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

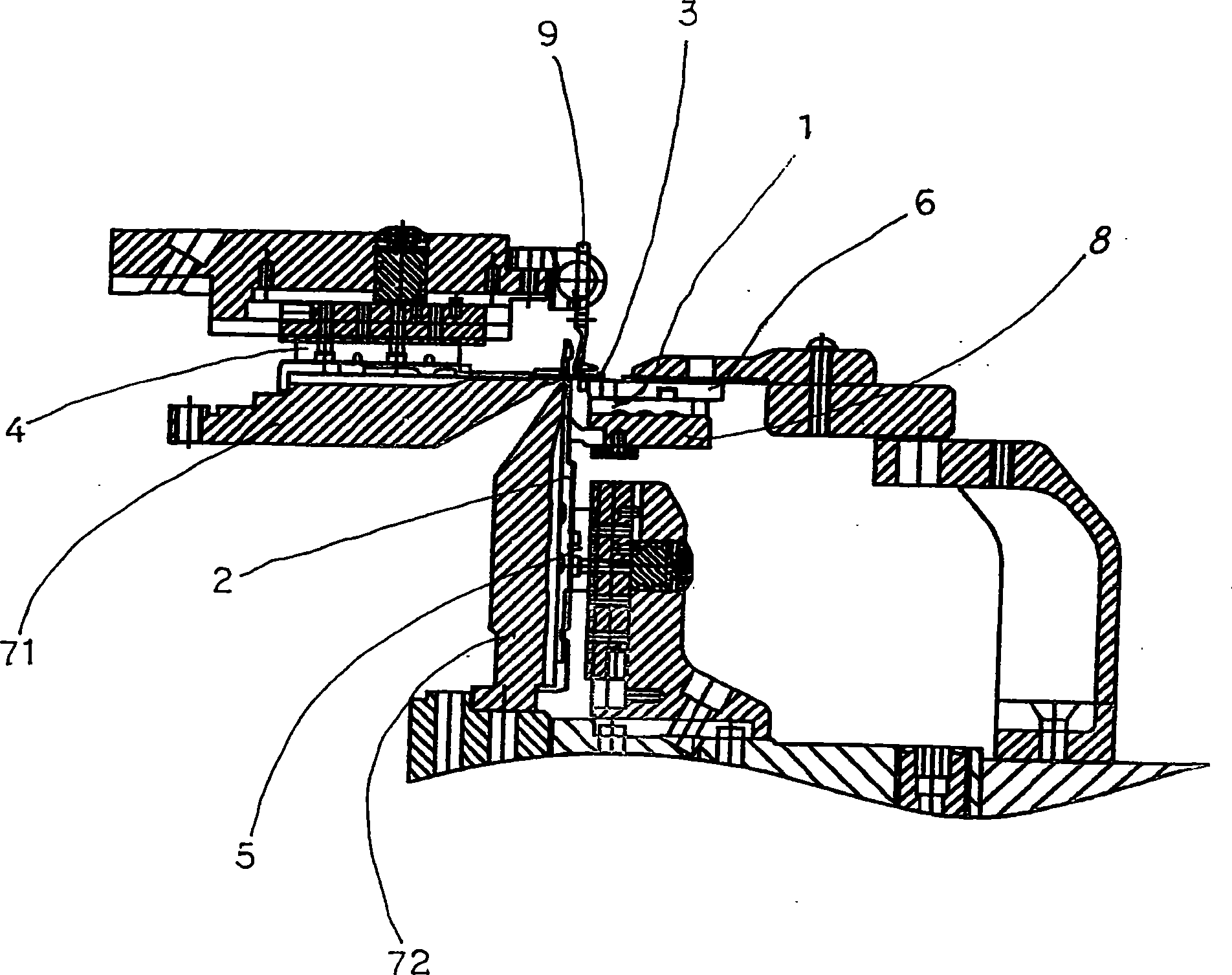

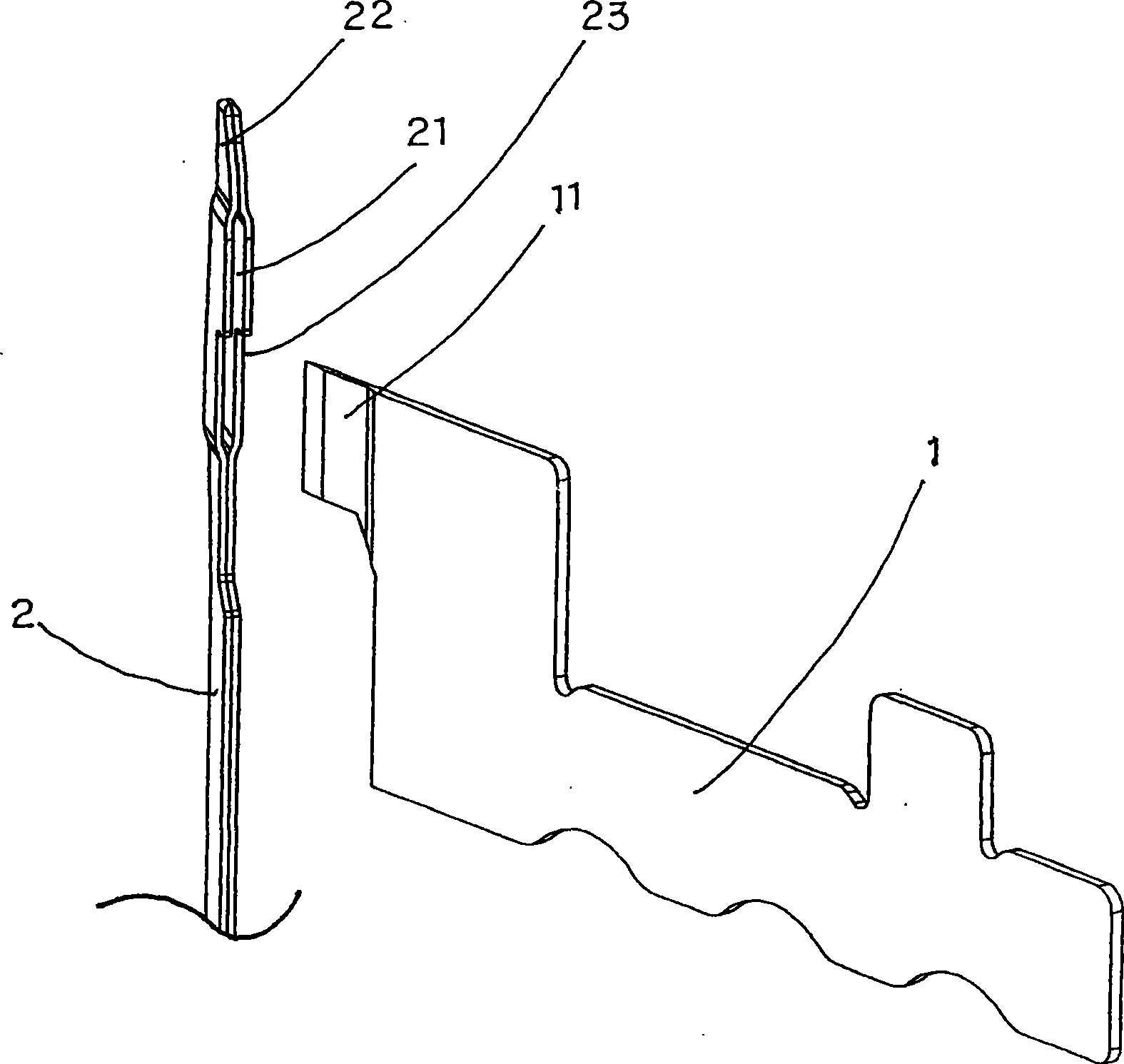

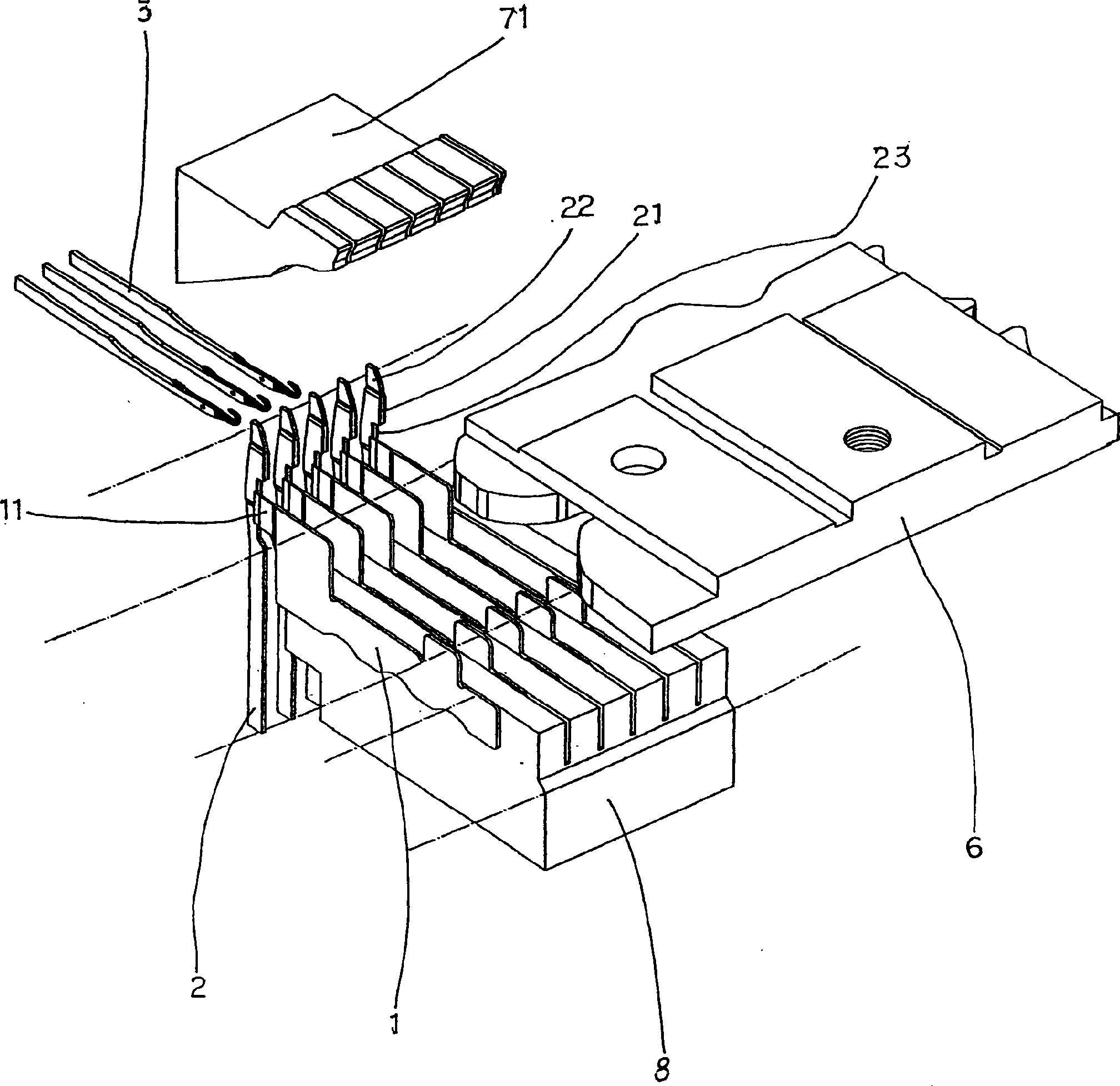

[0024] see Figure 1-3 , the basic components of the present invention are the same as those of a general circular knitting towel knitting machine, mainly that a thinner blade 11 is arranged at the front end of the yarn cutter 1, and a plurality of yarn cutters 1 are respectively placed in the ends of the raw cylinder 8. In the groove, and its movement trajectory is controlled by the yarn cutter triangle 6. The raising needle 2 is provided with a through cutting hole 21 at an appropriate position on its top, and a plurality of raising needles 2 are respectively placed in the lower needle cylinder. In the groove of 72, its motion track is then controlled by the lower cam 5, and a plurality of knitting needles 3 are respectively placed in the groove of the upper needle cylinder 71, and its motion track is also controlled by the upper cam 4.

[0025] With the above-mentioned components, please refer to 4-6. When the raising needle 2 rises, the knitting needle 3 advances the hooke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com