Dyeing process of fire retardant fibers

A flame-retardant fiber and process technology, which is applied in the field of flame-retardant fiber dyeing technology, can solve the problems of flame-retardant fiber being difficult to dye and dye, and achieve the effects of high production value, consistent effect, and good parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

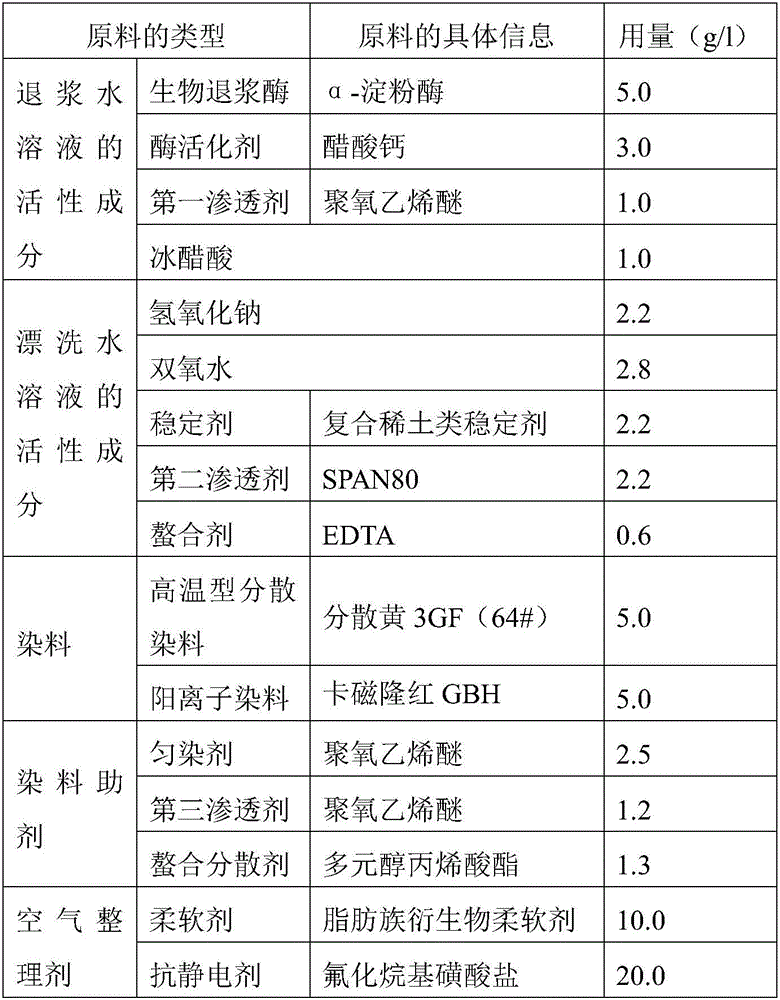

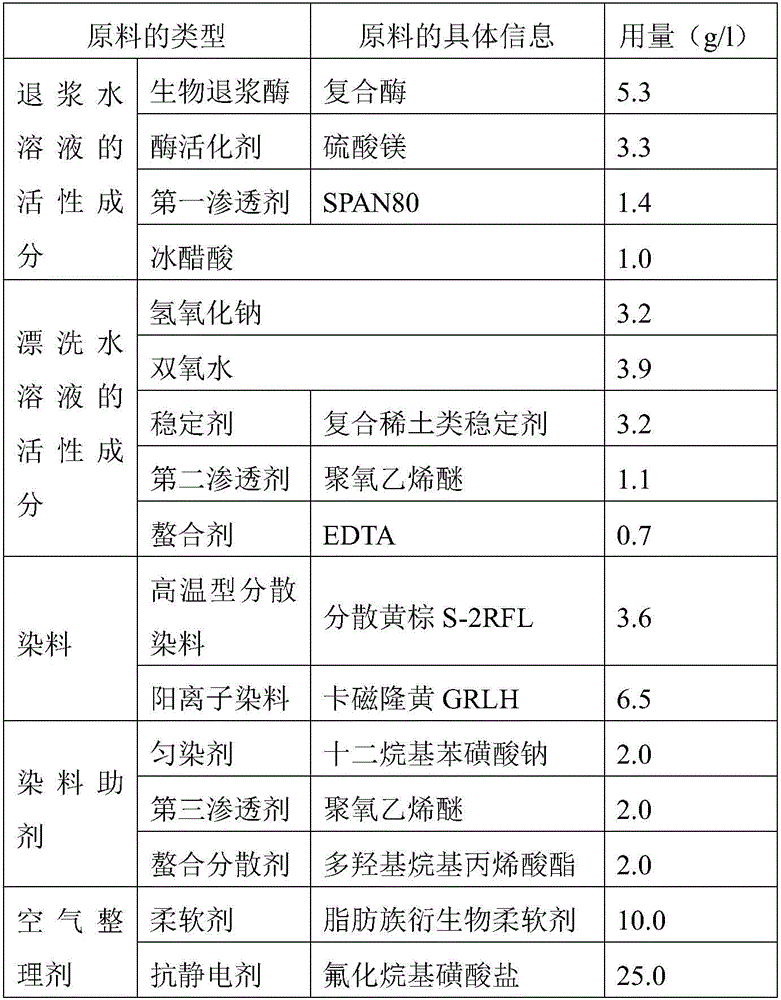

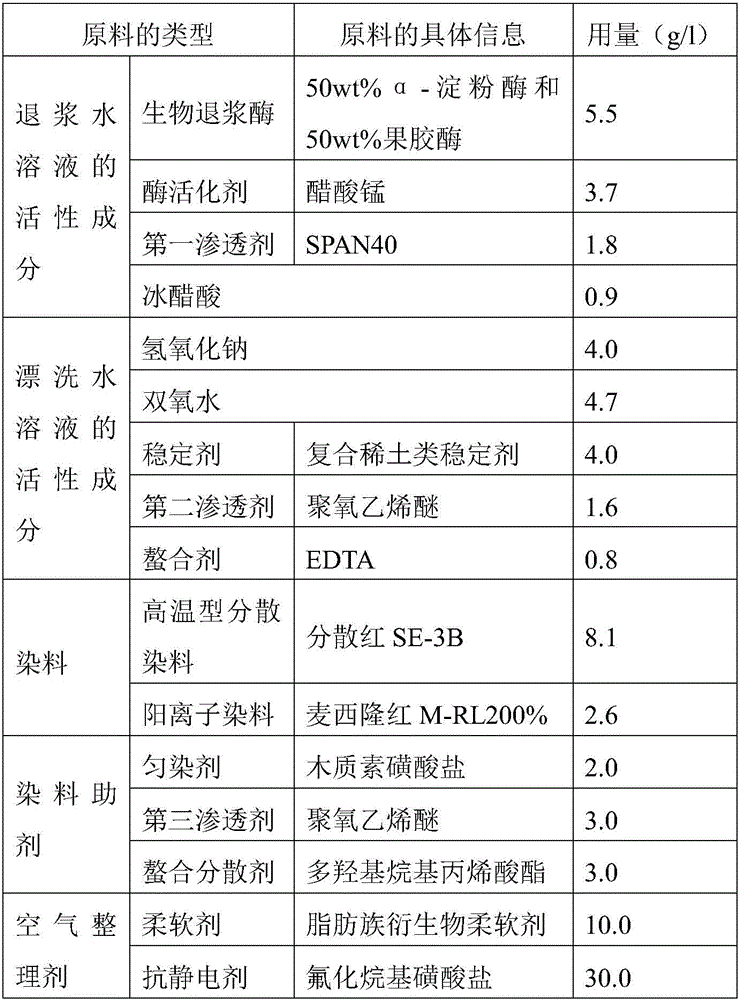

[0028] A kind of dyeing process of flame-retardant fiber, it comprises the steps:

[0029] Step 1, desizing treatment: Add the flame retardant fiber to the desizing aqueous solution at 50-60 °C, keep it warm for 10-24 hours, and then wash at 50-70 °C to remove the surface residue;

[0030] Step 2, rinsing treatment: take the flame-retardant fiber treated in step 1, add it to the rinsing aqueous solution at 95-100°C, keep it warm for 0.5-2hr, and then wash with water at 50-70°C to remove the surface residue;

[0031] Step 3, dehairing treatment: take the flame-retardant fiber treated in step 2, and remove the surface hairiness;

[0032] Step 4, dyeing treatment: take the flame-retardant fiber treated in step 3, add it to 15-35°C water, gradually raise the temperature of the water bath to 100-102°C, add dye when the water bath is 68-71°C Add dye auxiliaries at 95-100°C, keep warm at 100-102°C for 0.5-1hr; gradually raise the temperature of the water bath to 130-135°C, and keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com