Silk fiber prepared by modifying plant extracts and preparation method of silk fiber

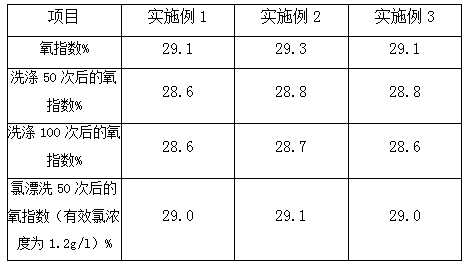

A plant extract and silk fiber technology, applied in plant fiber, fiber treatment, dyeing, etc., can solve the problems of less research on silk fiber modification, achieve good flame retardancy, high oxygen index, and color fastness to chlorine bleaching The effect of low reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

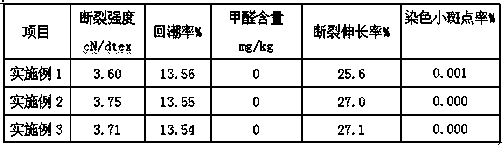

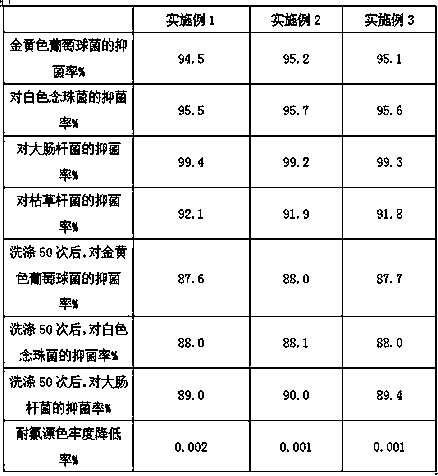

Examples

Embodiment 1

[0062] Embodiment 1 A kind of silk fiber prepared by modification of plant extract and its preparation method

[0063] A kind of silk fiber prepared by plant extract modification of the present invention and preparation method thereof, comprises the following steps:

[0064] Step 1. Preprocessing

[0065] 1) Soaking: Remove impurities from viscose filaments, ultrasonically clean them with deionized water and 1% dilute hydrochloric acid for 10 minutes, and then clean them with ultrapure water. After soaking at room temperature for 10 minutes, control the temperature between 25°C , let stand for 20h.

[0066] 2) Washing material: washing and immersing the above-mentioned silk fibers in washing immersion liquid, the washing temperature is 66° C. to obtain silk fibers;

[0067] The washing immersion solution is made of the following ingredients in parts by weight: 8 parts of Yuanming powder, 8 parts of sodium chloride, 2 parts of baking soda powder, 5 parts of sodium citrate, 0....

Embodiment 2

[0101] Embodiment 2 A kind of silk fiber prepared by plant extract modification and preparation method thereof

[0102] A kind of silk fiber prepared by plant extract modification of the present invention and preparation method thereof, comprises the following steps:

[0103] Step 1. Preprocessing

[0104] 1) Soaking: Remove the impurities from the viscose filaments, then ultrasonically clean them with deionized water and 1% dilute hydrochloric acid for 12 minutes, and then clean them with ultrapure water. After soaking at room temperature for 22 minutes, control the temperature between 48°C , let stand for 37h.

[0105] 2) Washing material: washing and soaking the above-mentioned silk fibers with washing immersion liquid, the washing temperature is 66-70° C. to obtain silk fibers;

[0106] The washing liquid is made up of the following ingredients in parts by weight: 9.8 parts of sodium bismuth powder, 5.8 parts of sodium chloride, 3.5 parts of baking soda powder, 4.2 parts...

Embodiment 3

[0140] Embodiment 3 A kind of silk fiber prepared by plant extract modification and its preparation method

[0141] A kind of silk fiber prepared by plant extract modification of the present invention and preparation method thereof, comprises the following steps:

[0142] Step 1. Preprocessing

[0143] 1) Soaking: Remove impurities from viscose filaments, ultrasonically clean them with deionized water and 1% dilute hydrochloric acid for 15 minutes, and then clean them with ultrapure water. After soaking at room temperature for 30 minutes, control the temperature between 50°C , let stand for 50h.

[0144] 2) Washing material: washing and soaking the above-mentioned silk fibers with washing immersion liquid, the washing temperature is 70° C. to obtain silk fibers;

[0145] The washing immersion solution is made of the following ingredients in parts by weight: 12 parts of Yuanming powder, 2 parts of sodium chloride, 5 parts of baking soda powder, 2 parts of sodium citrate, 0.2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com