Unstable island type PA6/PU suede superfine fiber synthetic leather pad-dyeing process by using vat dye

A superfine fiber and synthetic leather technology, applied in the field of acrylic fiber processing, can solve the problems of unsatisfactory vat dye dyeing effect, low dyeing rubbing fastness and soaping fastness, increased cohesive energy, etc., and achieves the distribution of microporous structure. The effect of uniform preservation, prevention of excessive local temperature, and favorable infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

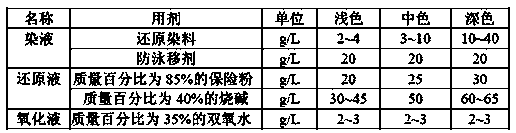

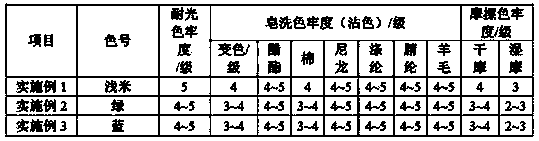

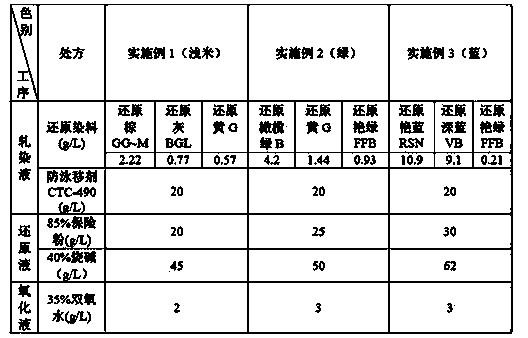

[0031] Examples 1 to 3 are specific implementations of the vat dye pad dyeing process for indeterminate island type PA6 / PU suede superfine fiber synthetic leather of the present invention, and Example 1 is the best implementation. Embodiment 1~3 pad dyeing process prescription, see Table 2.

[0032] Table 2 Example 1~3 Pad Dyeing Process Prescription

[0033]

[0034] Example 1

[0035] The indeterminate island type PA6 / PU suede superfine fiber synthetic leather obtained in Example 1 is light beige, and the color is prepared by using three kinds of vat dyes, vat brown GG~M, vat gray BGL, and vat yellow G.

[0036] In this embodiment, the indeterminate island type PA6 / PU suede superfine fiber synthetic leather vat dye pad dyeing process is characterized in that it includes the following steps:

[0037] Padding dyeing solution→infrared pre-baking→drying→baking→pad reducing solution→steaming→water washing→oxidation 3 times→soaping 2 times→water washing 2 times→drying;

[003...

Embodiment 2

[0046] The indeterminate island type PA6 / PU suede superfine fiber synthetic leather obtained in Example 2 is light beige, which is formulated with three kinds of vat dyes: vat olive green B, vat yellow G, and vat bright green FFB.

[0047] In this embodiment, the indeterminate island type PA6 / PU suede superfine fiber synthetic leather vat dye pad dyeing process is characterized in that it includes the following steps:

[0048] Padding dyeing solution→infrared pre-baking→drying→baking→pad reducing solution→steaming→water washing→oxidation 2 times→soaping 2 times→water washing 2 times→drying;

[0049] Among them, the padding dyeing solution: the padding method is one dipping and one padding, the padding temperature does not exceed 30°C, and the padding rate is 60%. The composition of the dyeing solution is vat dye and anti-swimming agent CTC-490; of vat dyes for fineness 2μm hollow dust-proof granular vat dyes.

[0050] Drying: The temperature is 113~115°C.

[0051] Baking: ...

Embodiment 3

[0057] The indeterminate island type PA6 / PU suede superfine fiber synthetic leather obtained in Example 3 is light beige, which is formulated by using three kinds of vat dyes: vat brilliant blue RSN, vat dark blue VB, and vat brilliant green FFB.

[0058] In this embodiment, the indeterminate island type PA6 / PU suede superfine fiber synthetic leather vat dye pad dyeing process is characterized in that it includes the following steps:

[0059] Padding dyeing solution→infrared pre-baking→drying→baking→pad reducing solution→steaming→water washing→oxidation 4 times→soaping 2 times→water washing 2 times→drying;

[0060] Among them, the padding dyeing solution: the padding method is one dipping and one padding, the padding temperature does not exceed 30°C, and the padding rate is 70%. The composition of the dyeing solution is vat dye and anti-swimming agent CTC-490; of vat dyes for fineness 2μm hollow dust-proof granular vat dyes.

[0061] Drying: The temperature is 110~112°C.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com