Supersoft cotton-like polyesteramide fiber blended colored yarn and production method thereof

A cotton-like fiber and polyester amide technology, applied in the field of textile yarn, can solve the problems of difficult dyeing and poor spinnability, and achieve the effect of soft hand feeling, severe entanglement and complete color spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

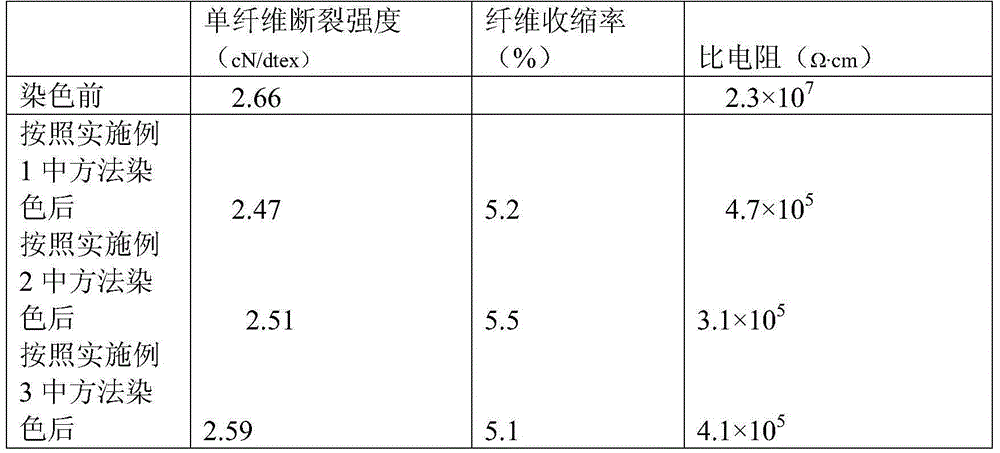

Embodiment 1

[0032] In this example, Archroma's Foron S-WF series was used for dyeing.

[0033] The dyeing pH value is 4.6, the dyeing temperature is 80°C, the heating rate is 0.5°C / min, and the holding time is 90min.

Embodiment 2

[0035] The polyamide ester supersoft cotton-like fiber described in this example is dyed by Huntsman's TERASILW / WW series.

[0036] The specific dyeing process is as follows: the dyeing pH value is 4.6, the dyeing temperature is 90°C, the heating rate is 1.0°C / min, the holding time is 70min, the liquid is drained after dyeing, and the reduction cleaning is performed after two washes.

Embodiment 3

[0038] The polyamide ester supersoft cotton-like fiber described in this example is dyed by DyStar's DianixXF / SF series.

[0039] The specific dyeing process is as follows: the dyeing pH value is 6.0, the dyeing temperature is 105°C, the heating rate is 1.5°C / min, and the holding time is 40min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com