A kind of water-based nano pigment ink for textile printing

A technology of nano-pigment and water-based pigment paste, which is applied in the field of ink, can solve the problems of poor color fastness to rubbing, poor film-forming and rheological properties, hard hand feeling of printed fabrics, etc., and achieve comfortable fabric hand feeling , Guarantee printing fluency and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

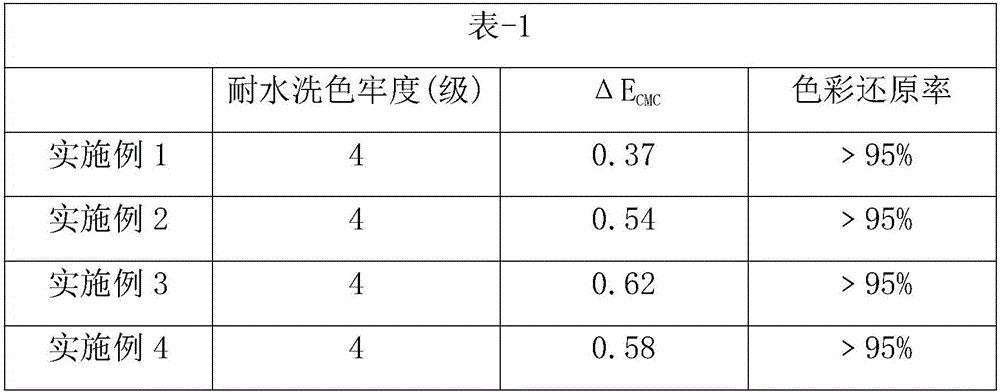

Examples

Embodiment 1

[0028] This example is the preparation embodiment of black water-based nano pigment ink

[0029] (1) Add 65.55 parts by mass of deionized water, 3.4 parts by mass of glycerin, and 2 parts by mass of triethylene glycol monobutyl ether into the liquid agitator at a stirring speed of 1000r / min, stir for 0.5 hours, and stir the solution evenly (2) 2.7 parts by mass of maleic anhydride resin and 6.8 parts by mass of alkyd resin are added to the solution, the temperature is raised to 60° C., and stirring is continued at a stirring speed of 1000 r / min. After stirring for 1 hour, the water-based resin is completely dissolved;

[0030] (3) Add 1 mass part of BYK346 and 0.05 mass part of 2-imidazolidinone into the solution, continue stirring at a stirring speed of 1600r / min, stir for 3 hours, and stir the solution evenly;

[0031] (4) Add 12.9 parts by mass of water-based black pigment paste (C.I. Pigment Black 6) into the solution, continue to stir, the stirring speed is 1600r / min, and...

Embodiment 2

[0035] This example is the preparation embodiment of blue water-based nano pigment ink

[0036] (1) Add 50.9 parts by mass of deionized water, 4.2 parts by mass of glycerin, and 3.6 parts by mass of triethylene glycol monobutyl ether into a liquid agitator at a stirring speed of 1000r / min, stirring for 0.5 hours, and stirring the solution evenly ;

[0037] (2) Add 5.2 parts by mass of ethylene acid resin and 9.5 parts by mass of alkyd resin into the solution, raise the temperature to 60° C., continue stirring at a stirring speed of 1000 r / min, and stir for 1 hour to completely dissolve the water-based resin;

[0038] (3) Add 1.5 parts by mass of Surfynol 465 and 0.2 parts by mass of 2-imidazolidinone into the solution, continue to stir at a stirring speed of 1600r / min, stir for 3 hours, and stir the solution evenly;

[0039] (4) Add 15.3 parts by mass of water-based blue pigment paste (C.I. Pigment Blue 15:3) into the solution, continue to stir, the stirring speed is 1600r / mi...

Embodiment 3

[0043] This example is the preparation embodiment of red water-based nano pigment ink

[0044] (1) Add 52.6 parts by mass of deionized water, 5.2 parts by mass of glycerin, and 3.7 parts by mass of triethylene glycol monobutyl ether into the liquid agitator at a stirring speed of 1000r / min, stir for 0.5 hours, and stir the solution evenly ;

[0045] (2) Add 6.3 parts by mass of maleic anhydride resin and 8.6 parts by mass of alkyd resin into the solution, raise the temperature to 60°C, continue stirring at a stirring speed of 1000r / min, stir for 1 hour, and the water-based resin is completely dissolved;

[0046] (3) Add 2 parts by mass of Surfynol 440 and 0.1 part by mass of 2-imidazolidinone into the solution, continue to stir at a stirring speed of 1600r / min, stir for 3 hours, and stir the solution evenly;

[0047] (4) Add 12.4 parts by mass of water-based red pigment paste (C.I. Pigment Red 175) into the solution, continue stirring at a stirring speed of 1600r / min, and nat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com