Nail-free module suspended ceiling

A technology of suspended ceiling and cladding keel, applied in the direction of ceiling, building components, buildings, etc., can solve the problems of affecting the service life, poor levelness of gypsum board, low efficiency, etc., and achieve the effect of rapid installation, convenient operation and good leveling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

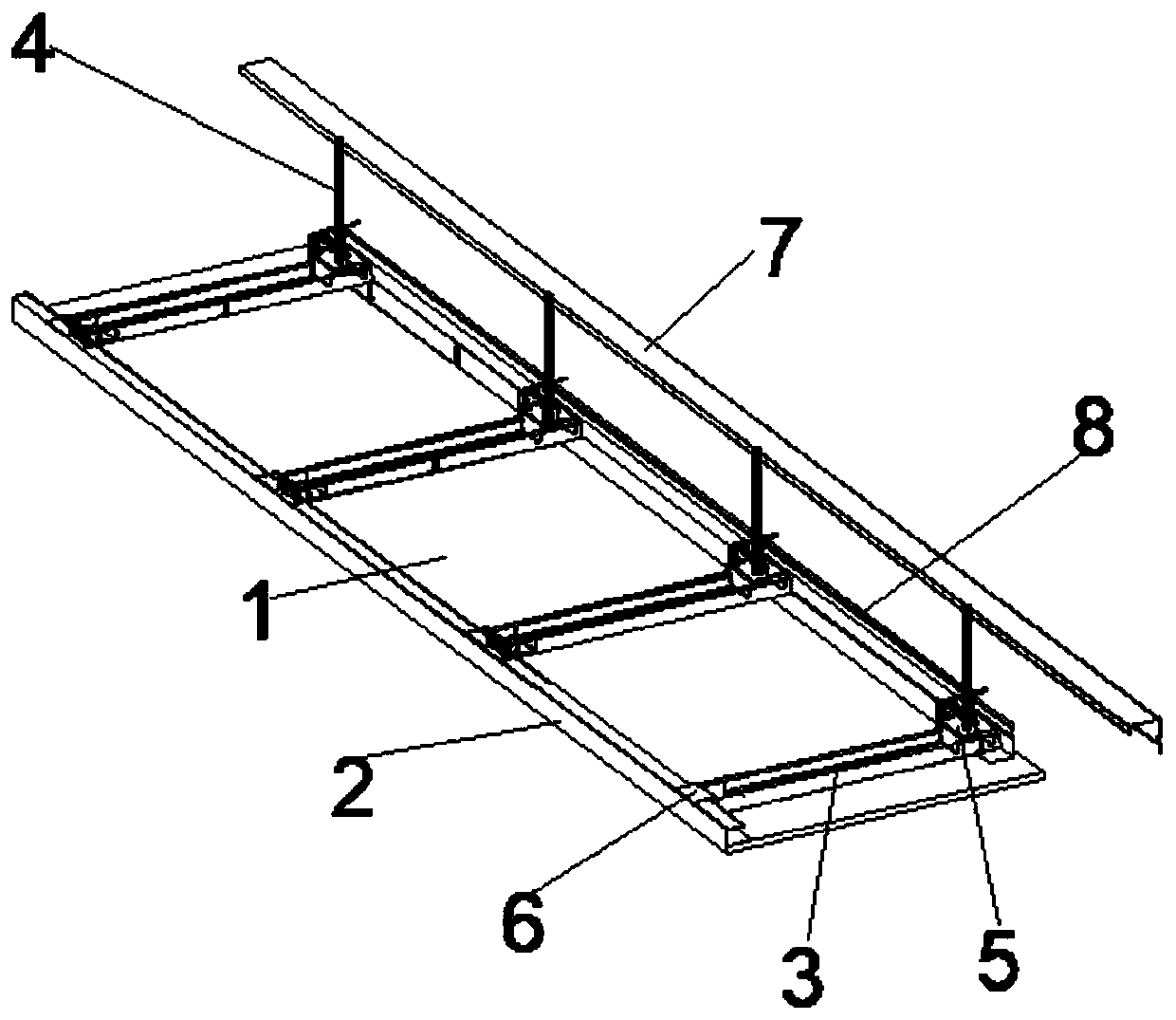

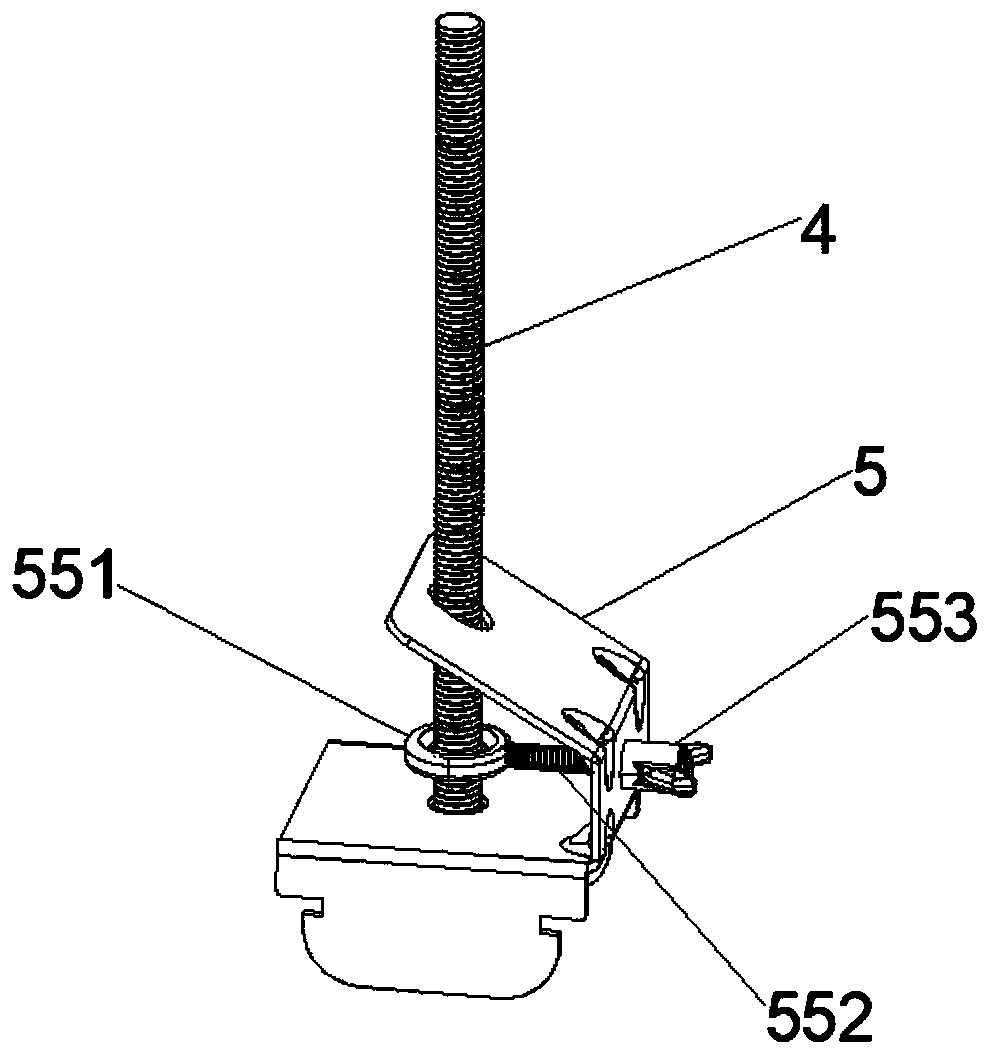

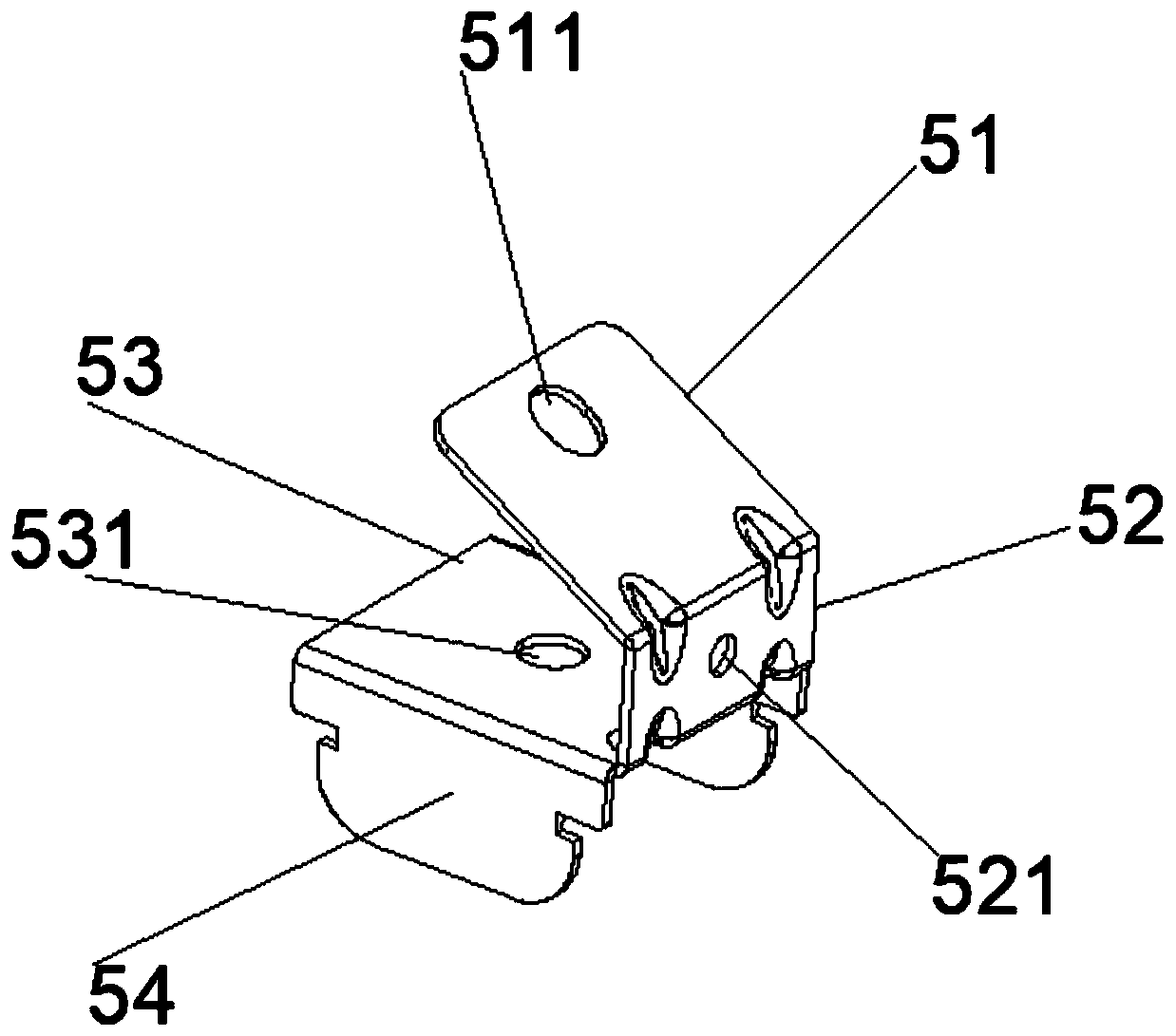

[0022] refer to Figure 1-4 , a nail-free modular ceiling, comprising a gypsum board 1, a cladding joist 3, and a side joist 2, the gypsum board 1 is fixed on the lower end of the cladding joist 3, and one end of the cladding joist 3 is fixedly connected to the side joist 2 , also includes a fixing rod and a leveling assembly 5, the upper end of the leveling assembly 5 is fixedly connected to the fixing rod, and the lower end is fixedly connected to the cladding keel 3 . The leveling assembly 5 includes a clamping part and a tightening part. The clamping part includes a guide plate 51, a connecting plate 52, a horizontal plate 53 and a vertical locking tooth 54 integrally connected in sequence. The tightening part includes a fixing ring 551, the fixed ring is provided with a screw rod 552, the screw rod 552 is provided with a nut 553, the nut 553 is an ingot nut, the guide plate 51 is provided with a first through hole 511, and the connecting plate 52 is provided with a first ...

Embodiment 2

[0025] refer to Figure 1-5 , during installation, fix the side keel 2 on the top of the wall in advance, fix the top keel 7 on the top floor of the house, fix the top of the screw rod 4 on the installed top keel 7, install the leveling component 5 at the bottom, and place the plaster The plate 1 is fixed on the cladding keel 3 by self-tapping screws, one end of the cladding keel 3 is lapped on the side keel 2 through the edge pendant 6, and the other end is inserted into the vertical locking tooth 54 of the leveling assembly 5, loosen the ingot nut, and adjust Adjust the height of the leveling component 5 on the screw rod 4 to adjust the level of the gypsum board 1, and then tighten the ingot nut. After the gypsum board 1 is installed and adjusted to the level, install the light groove 9 on the end of the gypsum board 1 away from the side keel 2, and Long sealing plate 10 and lateral short sealing plate 11 get final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com