High-precision flat shade cloth dyeing process

A high-precision, shading cloth technology, applied in the field of textile dyeing, can solve the problems of long wet processing time, affecting the fabric feel, large sewage discharge, etc., to improve color fastness, ensure dyeing uniformity, and efficient dyeing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

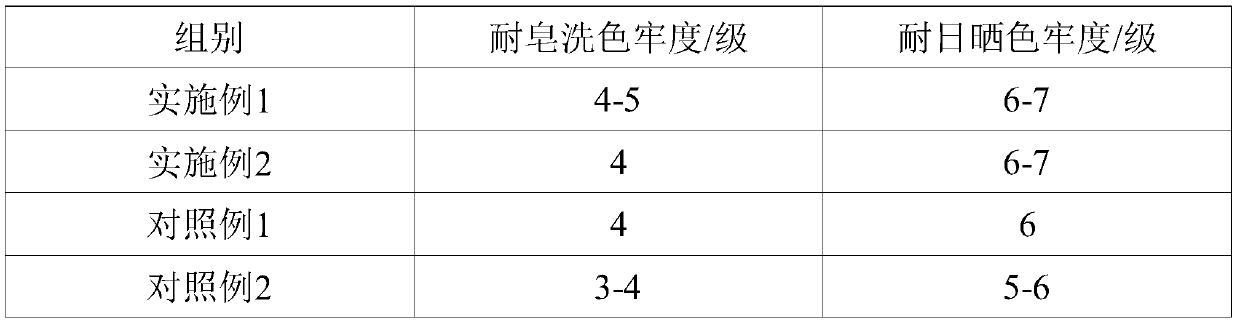

Examples

Embodiment 1

[0041] (1) Dye liquor preparation: Add 3kg of disperse dyes, 2kg of reactive dyes and 5kg of leveling agent to 90kg of water at 55°C, the leveling agent consists of glucoside and L-glutamine with a mass ratio of 3:0.5, stir to dissolve, get the dye solution;

[0042] (2) Dyeing: immerse 5kg of polyester-cotton blended yarn into the dyeing solution, the bath ratio is controlled at 1:20, the initial temperature of the dyeing solution is set at 50°C, and heated to 86°C at a heating rate of 2°C / min for 30 minutes, and then Add 3kg color fixing agent polyallyl glycol, continue to heat at 2°C / min to 112°C for 15min;

[0043] (3) Washing: The polyester-cotton blended yarn after the above dyeing process enters the washing process. The washing is divided into three stages. The washing temperature in the first stage is set at 50 ° C. After washing for 15 minutes, the waste liquid is drained; and then The second stage of water washing, the temperature of the second stage of water washin...

Embodiment 2

[0047] The color-fixing agent consumption in embodiment 1 is revised to 2kg, all the other are exactly the same as embodiment 1.

[0048] (1) Dye liquor preparation: Add 3kg of disperse dyes, 2kg of reactive dyes and 5kg of leveling agent to 90kg of water at 55°C, the leveling agent consists of glucoside and L-glutamine with a mass ratio of 3:0.5, stir to dissolve, get the dye solution;

[0049](2) Dyeing: immerse 5kg of polyester-cotton blended yarn into the dyeing solution, the bath ratio is controlled at 1:20, the initial temperature of the dyeing solution is set at 50°C, and heated to 86°C at a heating rate of 2°C / min for 30 minutes, and then Add 2kg color-fixing agent polyallyl glycol, continue heating to 112°C at a heating rate of 2°C / min and keep it warm for 15min;

[0050] (3) Washing: The polyester-cotton blended yarn after the above dyeing process enters the washing process. The washing is divided into three stages. The washing temperature in the first stage is set ...

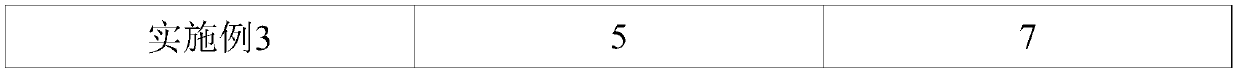

Embodiment 3

[0068] In embodiment 1, increase finishing process, all the other are completely with embodiment 1.

[0069] (1) Dye liquor preparation: Add 3kg of disperse dyes, 2kg of reactive dyes and 5kg of leveling agent to 90kg of water at 55°C, the leveling agent consists of glucoside and L-glutamine with a mass ratio of 3:0.5, stir to dissolve, get the dye solution;

[0070] (2) Dyeing: immerse 5kg of polyester-cotton blended yarn into the dyeing solution, the bath ratio is controlled at 1:20, the initial temperature of the dyeing solution is set at 50°C, and heated to 86°C at a heating rate of 2°C / min for 30 minutes, and then Add 2kg color-fixing agent polyallyl glycol, continue heating to 112°C at a heating rate of 2°C / min and keep it warm for 15min;

[0071] (3) Finishing: Immerse the polyester-cotton blended yarn dyed above into the finishing agent, the bath ratio is controlled at 1:20, the temperature of the finishing agent is set at 75°C, and the temperature is kept for 30 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| shading coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com