Method for dyeing calcium alginate fiber/silk fiber blend fabric by macromolecular dye containing polyethylene amine molecular chain

A technology of calcium alginate fibers and macromolecular dyes, applied in the field of fiber dyeing, can solve the problems of inability to meet the dyeing requirements of calcium alginate fiber/silk fiber blended fabrics, and inability to achieve simultaneous dyeing of two fibers, and achieve good energy saving and reduction. Discharge effect, good industrialization prospect, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

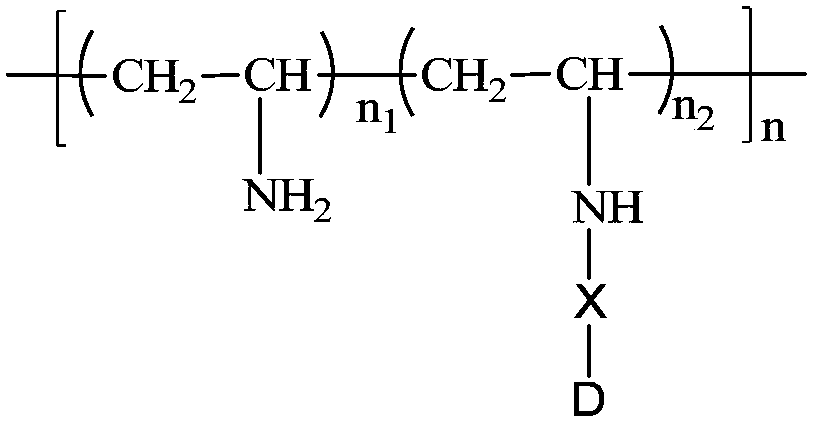

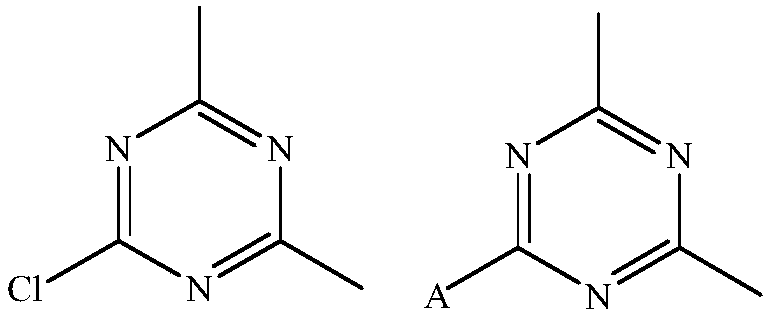

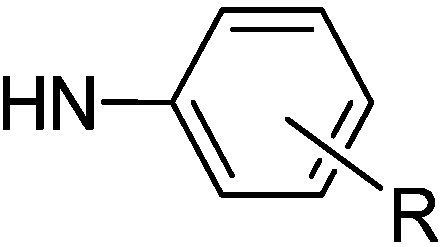

[0037] The structural formula of the polyvinylamine type macromolecular dye used in dyeing is:

[0038]

[0039] Among them, n 1 =50-60, n 2 =5-10, n=60-70

[0040] Dissolve 1g of the polyvinylamine-type macromolecular dye in 1000g of water, adjust the pH value to 8.5 with ammonia water, and mix evenly to obtain a dye liquor; then add 100g of calcium alginate fiber / silk fiber blended fabric into the dye liquor, and heat at 60°C Dyeing for 30min. After dyeing, take out the blended fabric, soak it in 4‰ neutral soap solution at 95°C for 10 minutes, and finally wash the seaweed fiber fully and dry it in the air.

Embodiment 2

[0042] The structural formula of the polyvinylamine type macromolecular dye used in dyeing is:

[0043]

[0044] Among them, n 1 =60-70,n 2 =10-15, n=70-80

[0045] Dissolve 1g of the polyvinylamine-type macromolecular dye in 2400g of water, adjust the pH value to 8.5 with ammonia water, and mix evenly to obtain a dye liquor; then add 80g of calcium alginate fiber / silk fiber blended fabric into the dye liquor, and heat Dyeing for 30min. After dyeing, take out the blended fabric, soak it in 4‰ neutral soap solution at 95°C for 10 minutes, and finally wash the blended fabric fully and dry it in the air.

Embodiment 3

[0047] The structural formula of the polyvinylamine type macromolecular dye used in dyeing is:

[0048]

[0049] Among them, n 1 =40-50, n 2 =15-20, n=60-70

[0050] Dissolve 1g of the polyvinylamine-type macromolecular dye in 2000g of water, use 10% sodium bicarbonate solution to adjust the pH value to 9, mix evenly to obtain a dye liquor; then add 50g of calcium alginate fiber / silk fiber blended fabric into the dye liquor , stained at 40°C for 40min. After dyeing, take out the blended fabric, soak it in 4‰ neutral soap solution at 95°C for 10 minutes, and finally wash the blended fabric fully and dry it in the air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com